Battery component disconnection control system, battery component and vehicle having same

A technology for control systems and battery components, applied in the field of vehicles, can solve problems such as time-consuming and economical costs, increased costs, and long response times, and achieve the effect of reducing maintenance time and economical costs and ensuring work safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0041] The "first" and "second" mentioned in the following embodiments do not represent an absolute distinction in structure or function, but are only for the convenience of description.

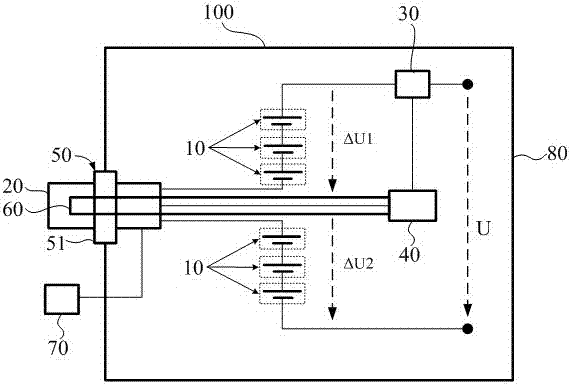

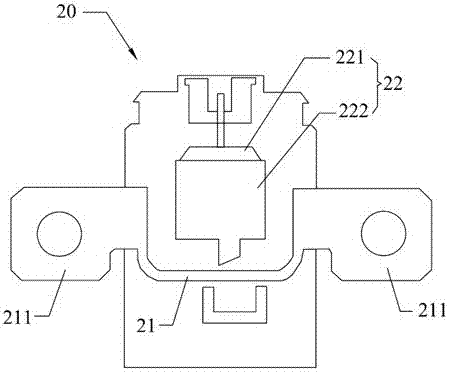

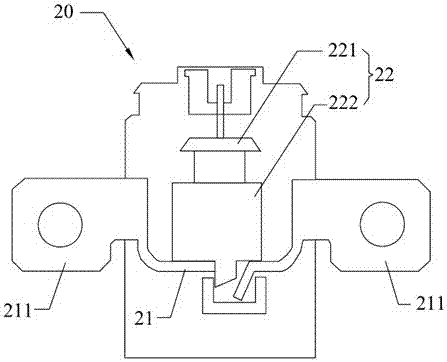

[0042] ginseng figure 1 , to introduce the first specific embodiment of the present invention applied to the disconnection control system of the battery assembly 100 . In this embodiment, the disconnect control system includes a disconnect switch 20 , a circuit information sensor 30 , a disconnect control module 40 and a manual circuit breaker 50 .

[0043]The battery assembly 100 includes a plurality of battery ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com