Novel sand washer

A sand washing machine, a new type of technology, applied in the field of sand washing machines, can solve the problems of high cost, high power, loss of fine sand, etc., and achieve the effect of improving utilization rate, ingenious structure, and simplifying the process of sand washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

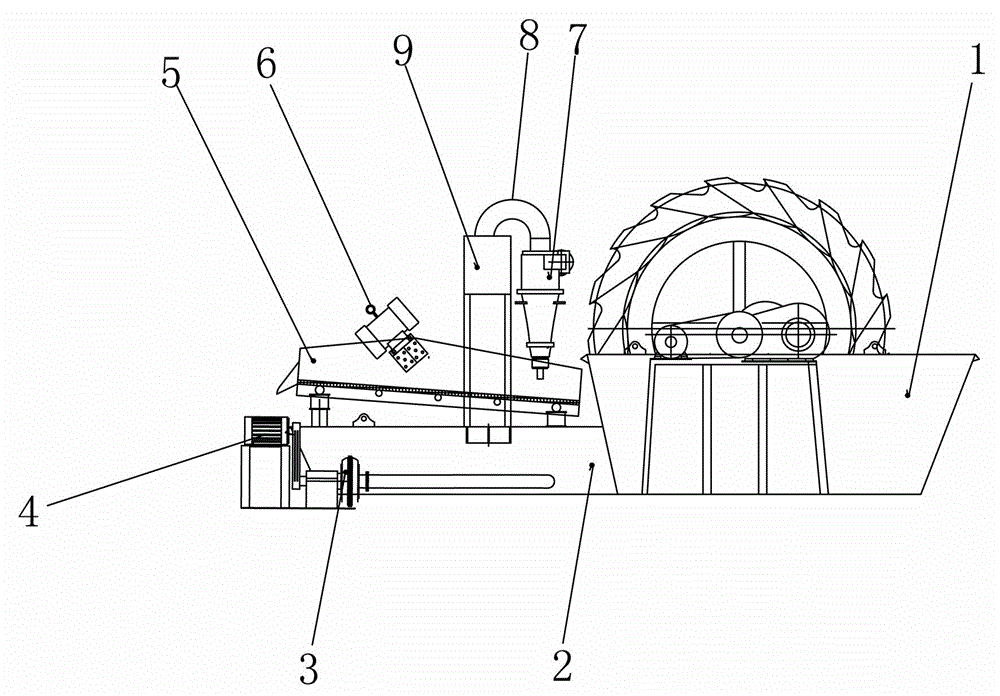

[0009] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Depend on figure 1 Given, the present invention includes a wheel type sand washing machine 1, one side of the discharge side of the wheel type sand washing machine 1 is fixedly connected with a cleaning tank 2, one side of the cleaning tank 2 is connected with a slurry pump 3, and the slurry pump 3 is connected with another A motor 4 is fixed at one end, a linear vibrating screen 5 is fixed above the cleaning tank 2, a vibrating motor 6 is fixed on the upper end of the linear vibrating screen 5, and the slurry pump 3 is connected with a separator 7 placed above the cleaning tank 2 through a pipeline. The lower port of 7 is placed above the linear vibrating screen 5, and the separator 7 is connected with the return box 9 through the inverted U-shaped pipe 8, and the lower port of the return box 9 is placed above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com