Pulse-jet screening machine

A technology of pulse blowing and powder sifting machine, which is used in sieve, solid separation, grid and other directions, can solve the problem of poor efficiency and effect of nano-scale carbon black particle or powder classification, increase cost, and super-diameter mixing. grading and other issues, to achieve high screening efficiency, improve service life, and avoid over-diameter mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

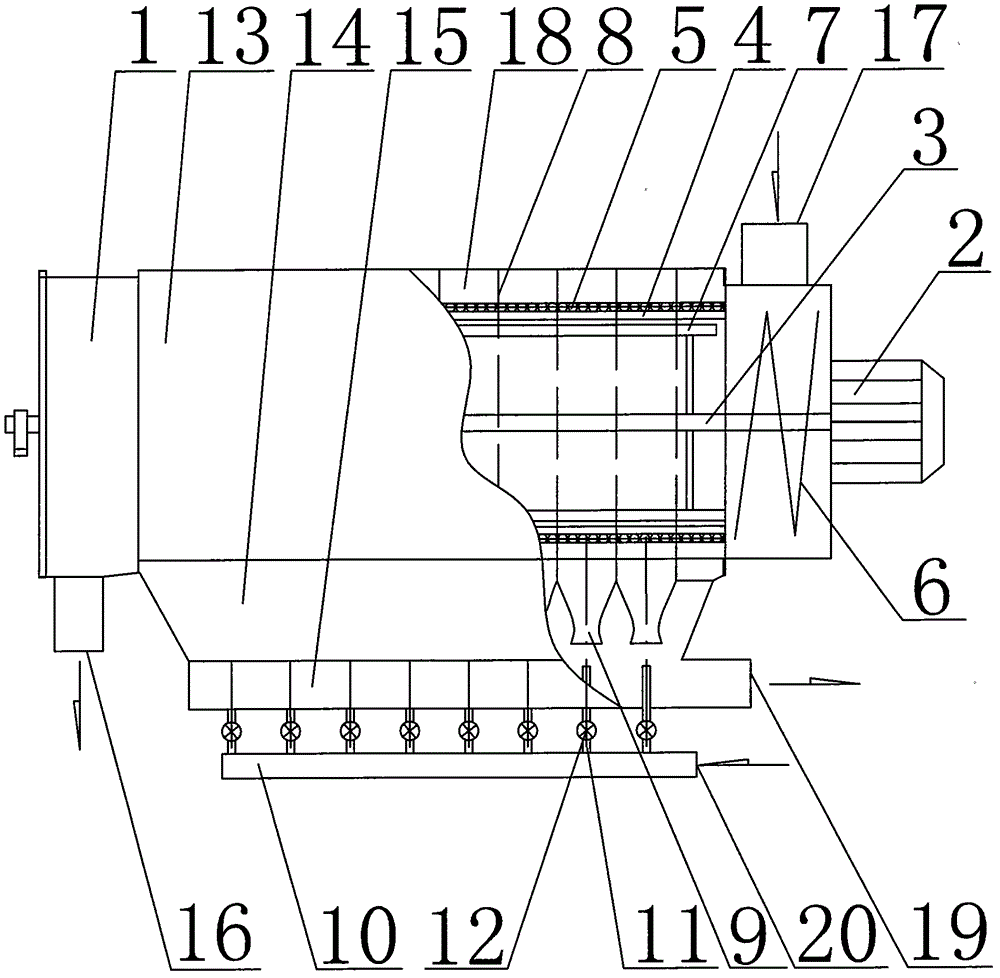

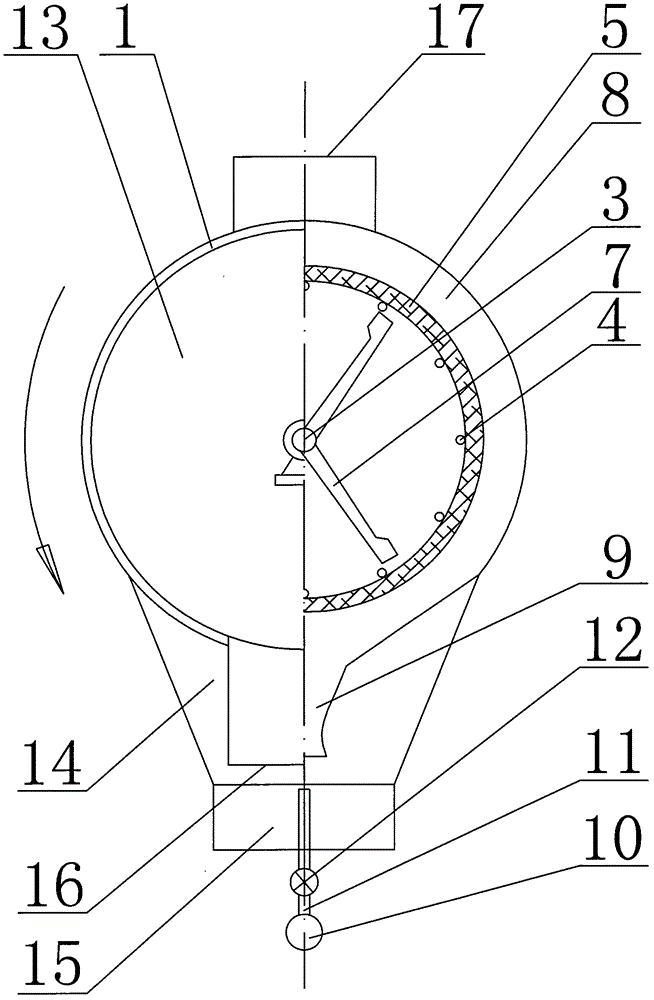

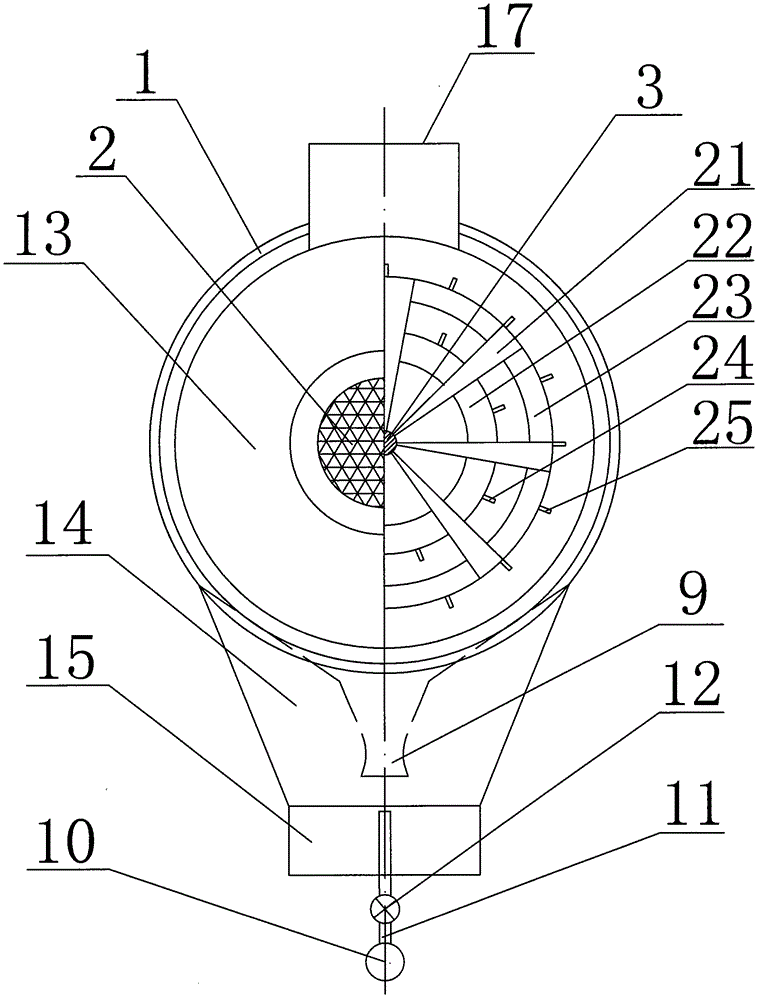

[0026] Such as figure 1 , figure 2 with image 3 As shown, the present invention discloses a pulse jet powder sieving machine, which includes a casing 1, a motor 2, a main rotating shaft 3, a grid frame 4 and a screen 5, and also includes an atomization assembly 6, a swirling paddle hammer 7, Injection cabin partition 8, venturi tube 9, compressed air main pipe 10, compressed air injection pipe 11 and electromagnetic pulse valve 12:

[0027] The casing 1 includes a screening part 13, a venturi tube setting part 14 and a compressed air blowing pipe setting part 15 from top to bottom. A slag discharge port 16 is provided under one end of the screening part 13, and a motor is provided at the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com