Electric arc 3D printing device and method for magnesium alloy tubular structural components

A tubular structure and 3D printing technology, which is applied in the field of magnesium alloy arc 3D printing additive manufacturing process, can solve problems that have not been reported, and achieve the effects of easy processing, improved product forming efficiency, and reduced product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

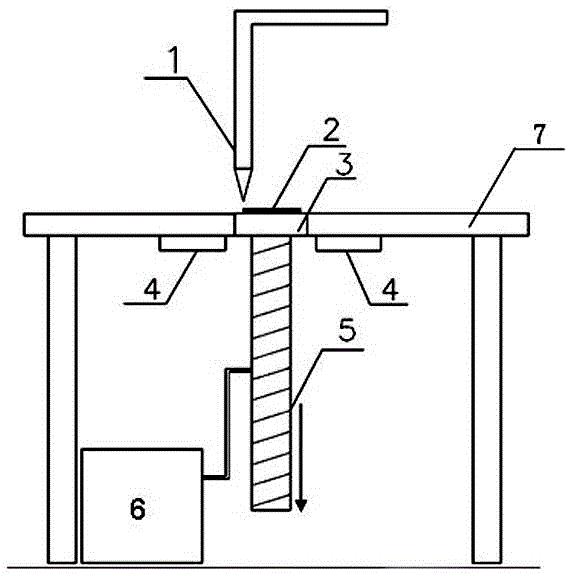

[0024] Such as figure 1 As shown, an arc 3D printing device for a magnesium alloy tubular structure includes a welding base, a copper component substrate, a cooling system, a linkage screw, a speed-regulating motor, and a welding torch. The component substrate is arranged on the welding base. The cooling system is arranged under the welding base, the component substrate and the linkage screw are fixedly connected, and the component substrate moves up and down with the linkage screw, the speed regulating motor drives the linkage screw, and the linkage screw Cooperating with the welding process, the welding torch is built up on the base plate of the component to form a magnesium alloy tubular str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com