Material-plug-type spiral feeder

A screw feeder, material plug technology, used in conveyors, loading/unloading, packaging and other directions, can solve the problems of poor material compressibility, unable to form material plugs, unable to compress materials, etc., to increase the compression strength, increase The effect of conveying thrust and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

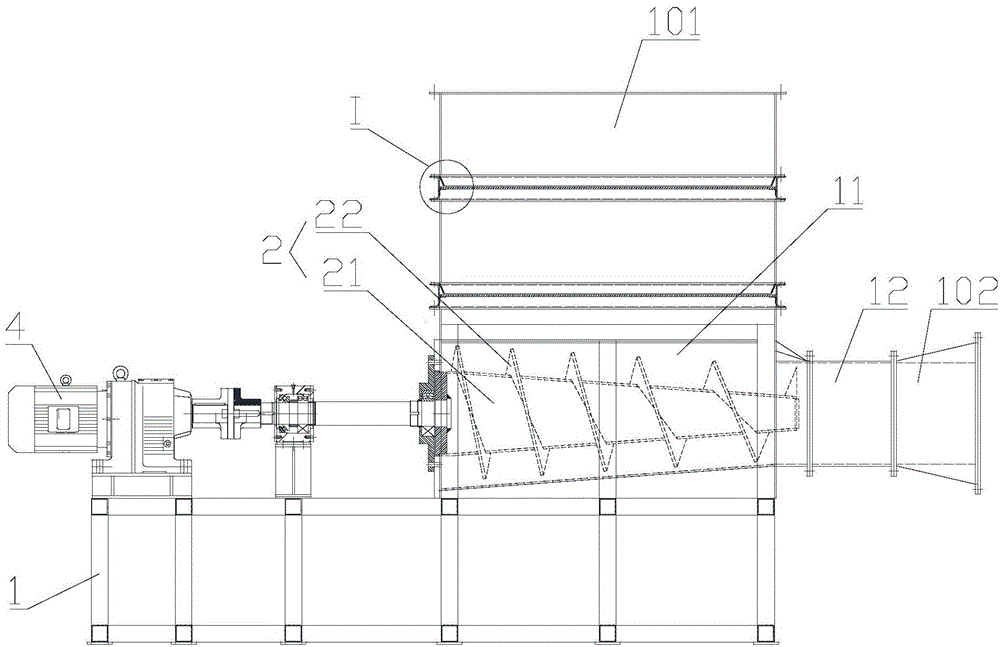

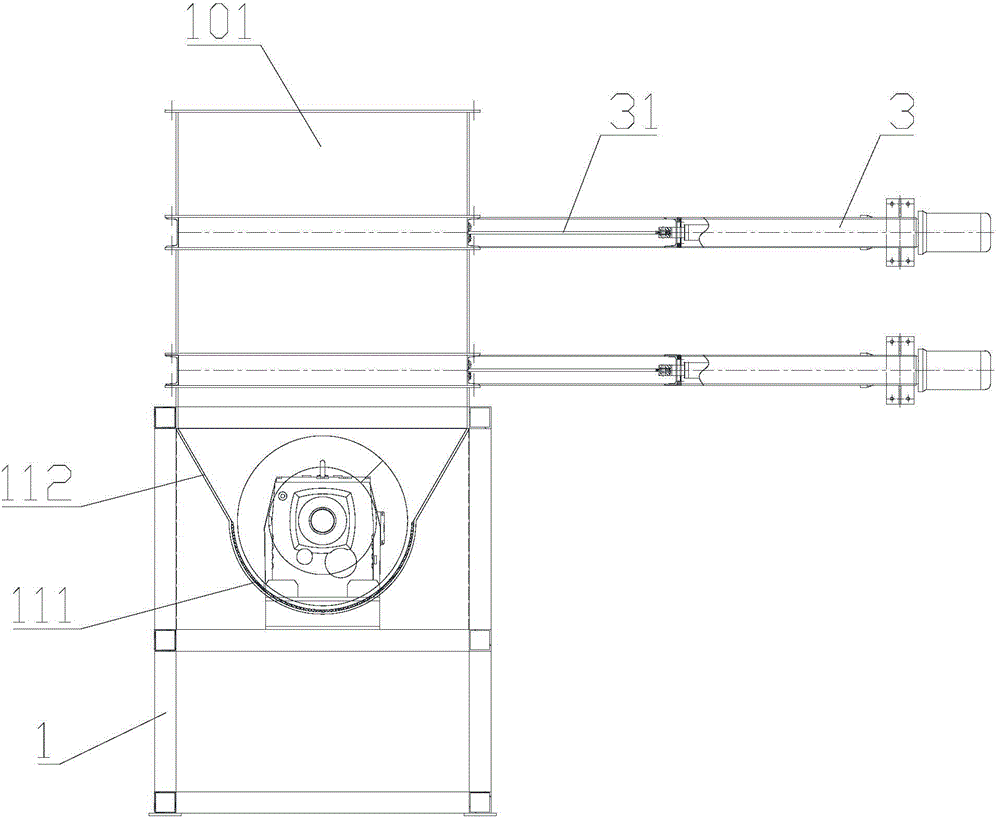

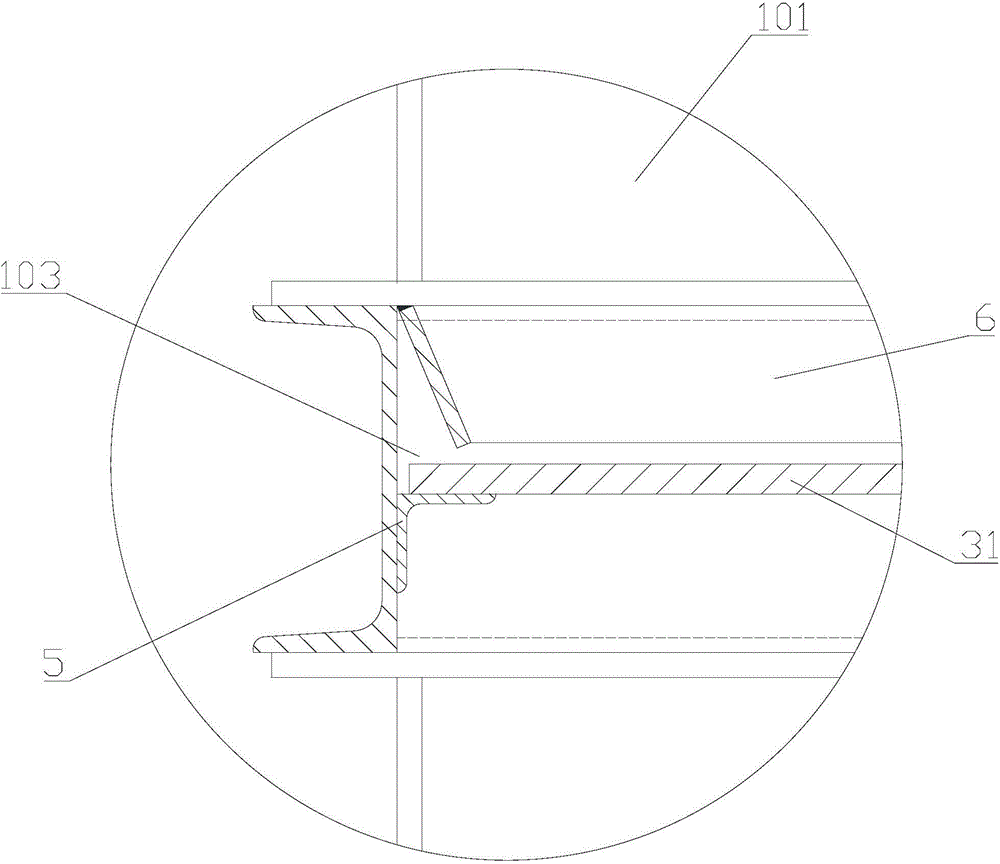

[0019] like figure 1 and figure 2 As shown, the plug-type screw feeder of this embodiment includes a casing 1, a compression area 11 and a plug area 12 are arranged in the casing 1, a screw shaft 2 is arranged in the compression area 11, and the rear end of the screw shaft 2 Part of the rotation is connected to the casing 1 and passes through the casing 1 to connect with the motor 4. The screw shaft 2 is driven to rotate by the motor 4. The motor 4 is electrically connected to the electric control system. The electric control system controls the movement of the motor 4. The compression zone 11 has The feeding port 101 and the output end, the feeding port 101 is located at the top of the casing 1, the output end is the front end of the screw shaft 2, the plug area 12 has an input end and a discharge port 102, the input end of the plug area 12 is connected to the compression The output end of zone 11 is connected, and the discharge port 102 is located at the front end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com