Flame retardant rubber composition and application thereof

A technology of flame retardant rubber and composition, applied in the field of rubber preparation, can solve the problems of tire fire, hidden dangers of life and property safety, human harm, etc., and achieve the effect of reducing the percentage content, improving the flame retardant performance, and improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

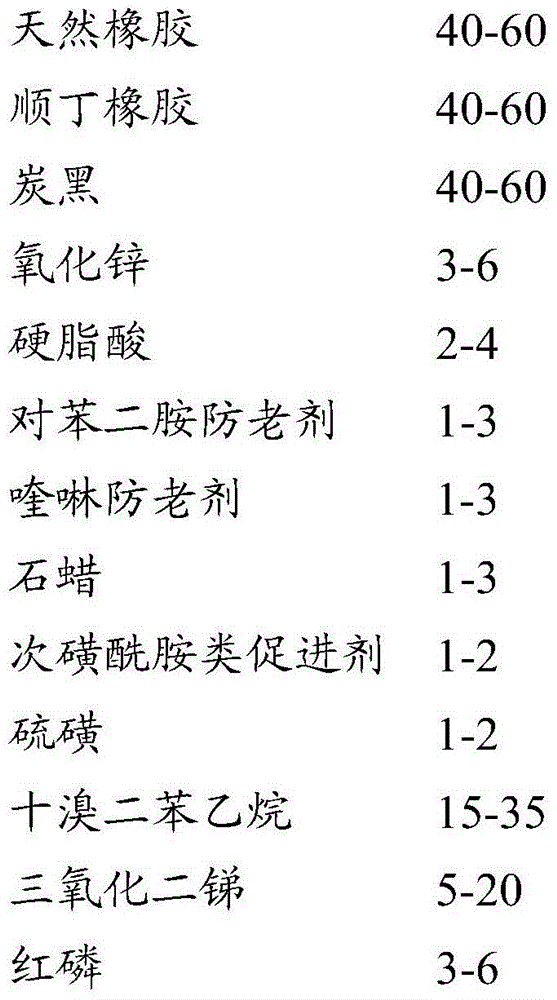

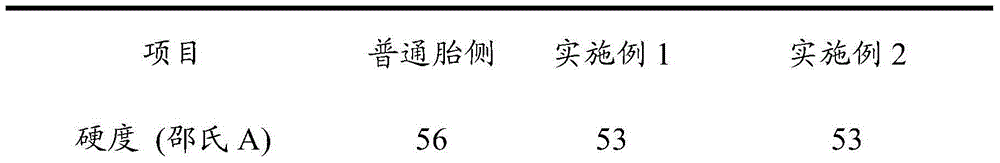

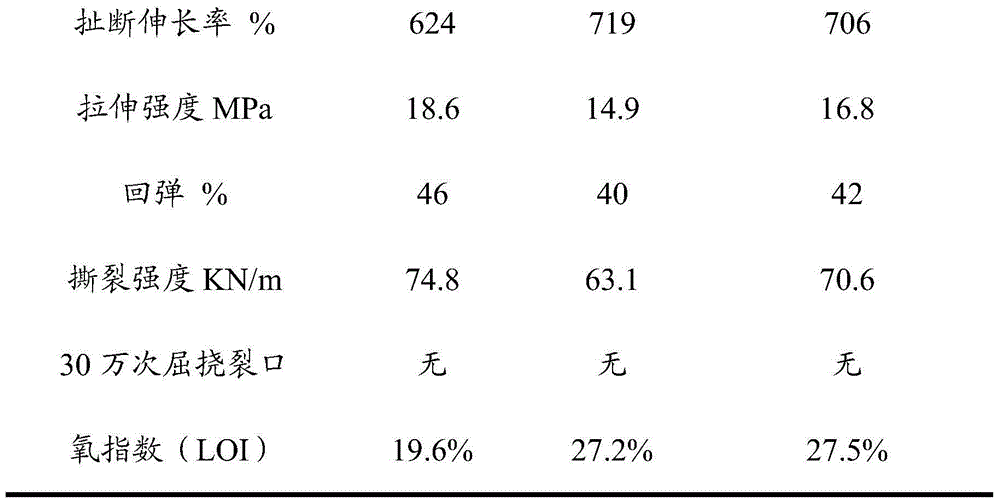

Embodiment 1

[0046] By weight: 40kg of natural rubber, 60kg of butadiene rubber, 50kg of carbon black, 3kg of zinc oxide, 2kg of stearic acid, 1kg of p-phenylenediamine antioxidant, 1kg of quinoline antioxidant, 1kg of paraffin wax, sulfenamide accelerator 1kg, sulfur 1kg, decabromodiphenylethane 30kg, antimony trioxide 10kg, red phosphorus 3kg.

[0047] The above-mentioned composition material is processed by a 3-stage mixing process, and the 3-stage mixing is carried out in an F370 type internal mixer, and the rotor speed is 10-60r / min; after the 3-stage mixing, the tablet is discharged from the mill; : Add 40kg of natural rubber, 60kg of butadiene rubber, 50kg of carbon black, 3kg of zinc oxide, 2kg of stearic acid, 1kg of p-phenylenediamine antioxidant, 1kg of quinoline antioxidant, 1kg of paraffin, 30kg of decabromodiphenylethane in one stage , antimony trioxide 10kg, red phosphorus 3kg, debinding temperature 165°C; the second stage is the rubber compound re-milling process; the third...

Embodiment 2

[0050] By weight: natural rubber 45kg, butadiene rubber 55kg, high wear-resistant carbon black 55kg, zinc oxide 5kg, stearic acid 4kg, p-phenylenediamine antioxidant 3kg, quinoline antioxidant 2kg, paraffin 3kg, decabromodi 25kg of phenylethane, 8kg of antimony trioxide, and 5kg of red phosphorus.

[0051]The above-mentioned composition material is processed by a 3-stage mixing process, and the 3-stage mixing is carried out in an F370 type internal mixer, and the rotor speed is 10-60r / min; after the 3-stage mixing, the tablet is discharged from the mill; : Add 40kg of natural rubber, 60kg of butadiene rubber, 50kg of carbon black, 3kg of zinc oxide, 2kg of stearic acid, 1kg of p-phenylenediamine antioxidant, 1kg of quinoline antioxidant, 1kg of paraffin, 30kg of decabromodiphenylethane in one stage , 10kg of antimony trioxide, 3kg of red phosphorus, debinding temperature 165°C; the second stage is the process of mixing rubber; the third stage adds 2kg of sulfur and 2kg of sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com