Alkylation product desulphurization and deacidifying method and device

A technology of alkylation and sulfuric acid, applied in the direction of adsorption purification/separation, only multi-stage serial refining process, etc., can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

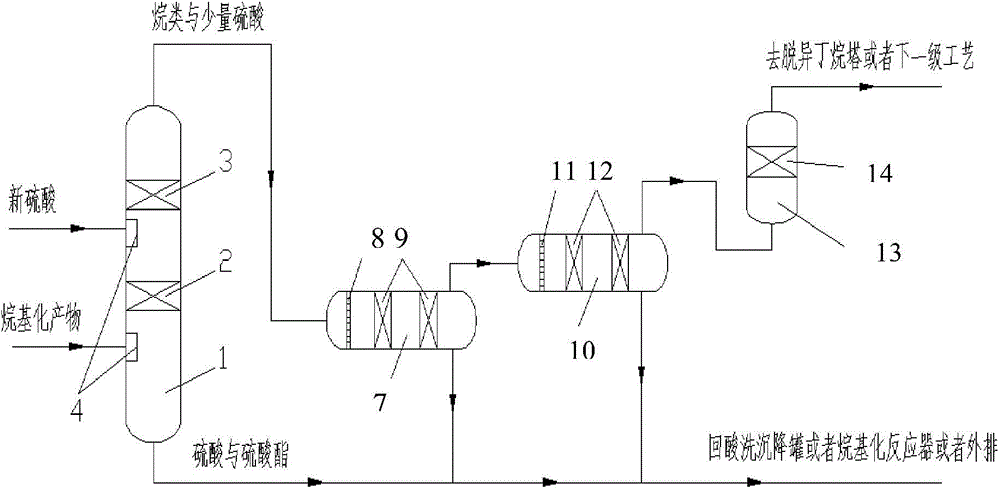

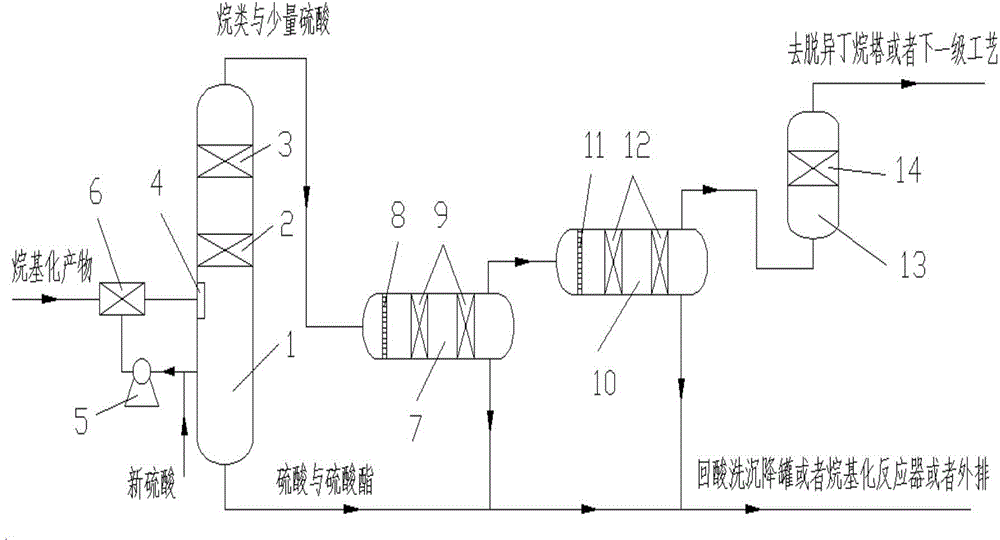

Method used

Image

Examples

Embodiment 1

[0070] A petrochemical company in Shandong tried the alkylation product desulfurization and deacidification device of the present invention to separate impurities such as sulfuric acid and sulfuric acid ester contained in the alkylation reaction product, so as to ensure the safety of downstream production devices and optimize the production process. Reduce the cost.

[0071] Its specific operation and effects are described as follows:

[0072] The main parameters of the desulfurization and deacidification process of the alkylation product: the working pressure of the pickling separation tank is 0.5MPa, the added new sulfuric acid=98% by weight, the treatment capacity of the alkylation product is 13t / h, and the sulfuric acid content is 15% by weight, and the sulfuric acid Esters = 2 to 3% by weight.

[0073] Shown in the following table 1 pickling separation tank design physical property parameters:

[0074] Table 1

[0075]

[0076] The design parameters of the first-sta...

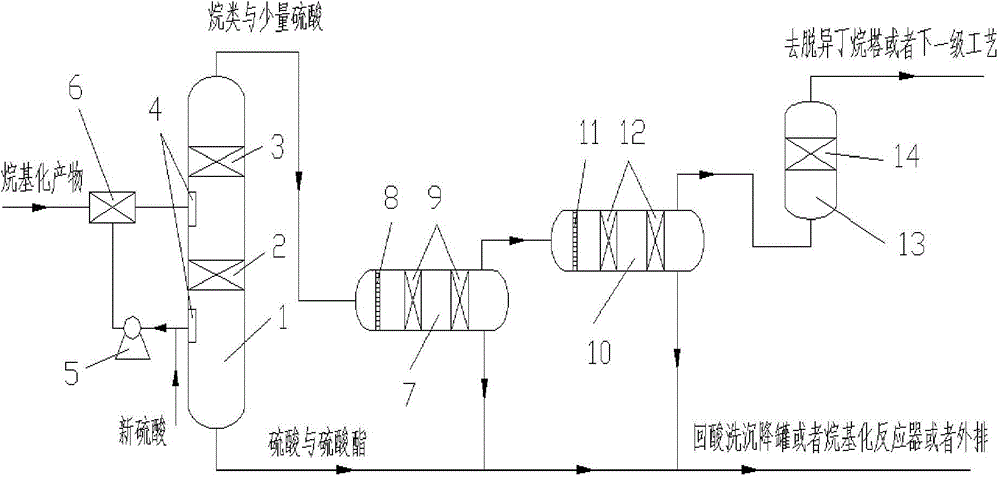

Embodiment 2

[0086] The alkylation pilot plant of a petrochemical company in Hebei Province tried the alkylation product desulfurization and deacidification device of the present invention, and separated impurities such as sulfuric acid and sulfuric acid ester contained in the alkylation reaction product to ensure that the downstream production equipment The safe and optimized production process reduces costs.

[0087] Its specific operation and effects are described as follows:

[0088] The main parameters of the desulfurization and deacidification process of the alkylation product: the working pressure of the pickling separation tank is 0.6MPa, the added new sulfuric acid=98% by weight, the processing capacity of the alkylation product is 500L / h, and the sulfuric acid content=18% by weight, the sulfuric acid Esters = 1 to 2.5% by weight.

[0089] Implementation process:

[0090] process such as figure 2 shown.

[0091] Driven by the circulation pump, the fresh sulfuric acid and the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com