A heating plate with high strength and convenient laying

A heating plate, high-strength technology, applied to pavement details, walls, roads, etc., can solve the problems of unsatisfactory snow melting and deicing effects, damage to road surface performance, and low degree of intelligence, so as to prevent deformation or displacement and reduce production costs Low, increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

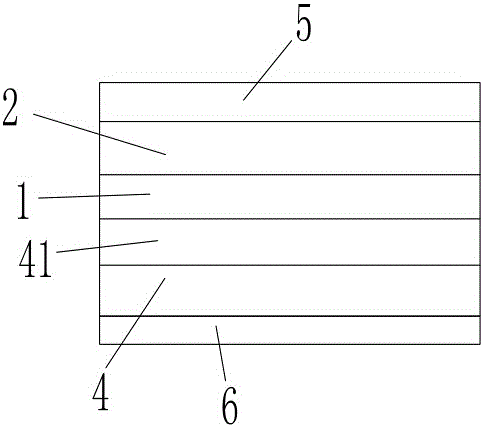

[0043] A high-strength heating plate that is easy to lay, comprising a heat insulating layer 4, a heat dissipation mesh layer 1, a heating wire layer 2 laid on the heat dissipation mesh layer, and a moisture-proof layer 6 arranged at the bottom of the heating plate, the heat dissipation mesh layer and the heating wire layer are located on the heat insulating layer, at least one surface of the heat dissipation mesh layer is laid with a heating wire layer, and a layer of reflective heat layer 41 is also covered on the upper surface of the heat insulating layer. The top layer is also covered with a layer of glass fiber mesh layer 5, and the moisture-proof layer, heat insulation layer and glass fiber mesh layer are fixedly connected with the heat dissipation mesh layer through connectors and / or wrapping, and the heat dissipation mesh layer is provided with multiple A connecting monomer for connecting the heat dissipation mesh layer and the heating wire layer, the heating wire layer...

Embodiment 2

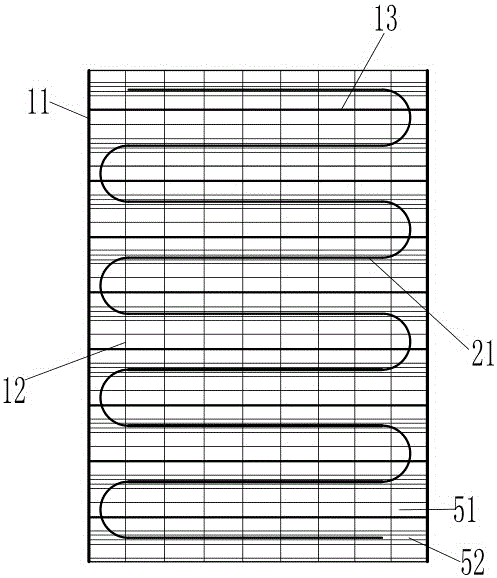

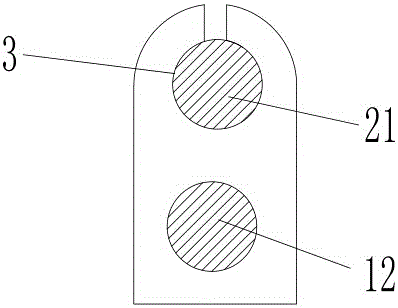

[0047] The difference from the above embodiment is that the heat dissipation mesh layer includes a single-layer flexible and rollable heat dissipation mesh layer, the heating wire layer is two layers arranged on the two surfaces of the heat dissipation mesh plate, and the heat dissipation mesh The network wires of the board include the shaped reinforcement frame wires 11 arranged in parallel on both sides of the heat dissipation screen and the main grid wires 12 interlaced between the two shaped reinforcement frame wires. The diameter of the shaped reinforced frame wires is larger than the main grid wires diameter. There is a fixed jacket ring with openings on both sides of the connecting monomer, and the middle part is a fixed section fixed on the mesh wire of the heat dissipation mesh layer by thermal fusion, and the heating wires located on both sides of the heat dissipation mesh plate They are respectively installed in the fixed jacket rings on both sides of the connecting...

Embodiment 3

[0049] The difference from the above-mentioned embodiment is that the connecting unit is provided with an open fixed jacket ring, and part of the heating wire and the local network cable of the heat dissipation mesh layer pass through the fixed jacket ring. The distance from the edge of the heating wire layer to the edge of the heat insulating layer is 9 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com