Synchronous double-valve electromagnetic control oil atomizer

An electromagnetic control and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problem of reducing valve flow, slowing the seating speed of the needle valve of the fuel injector, and reducing the sealing performance of the pilot ball valve, etc. The problem, achieve the effect of increasing rising speed and attenuation, ensuring fast response characteristics, and accelerating response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

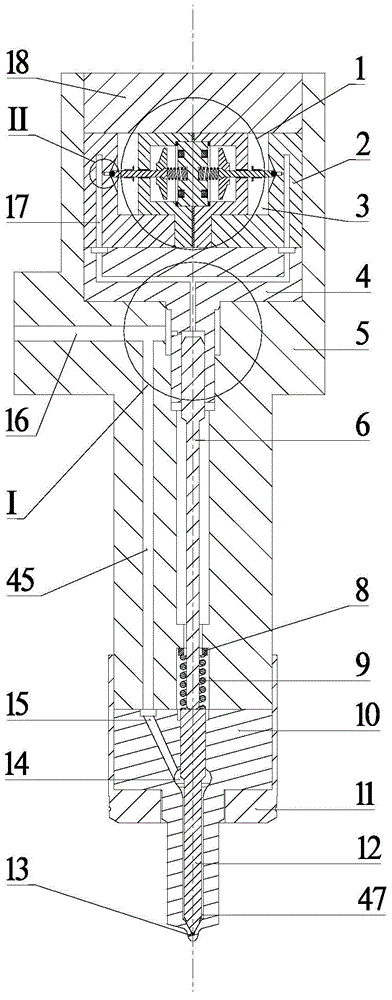

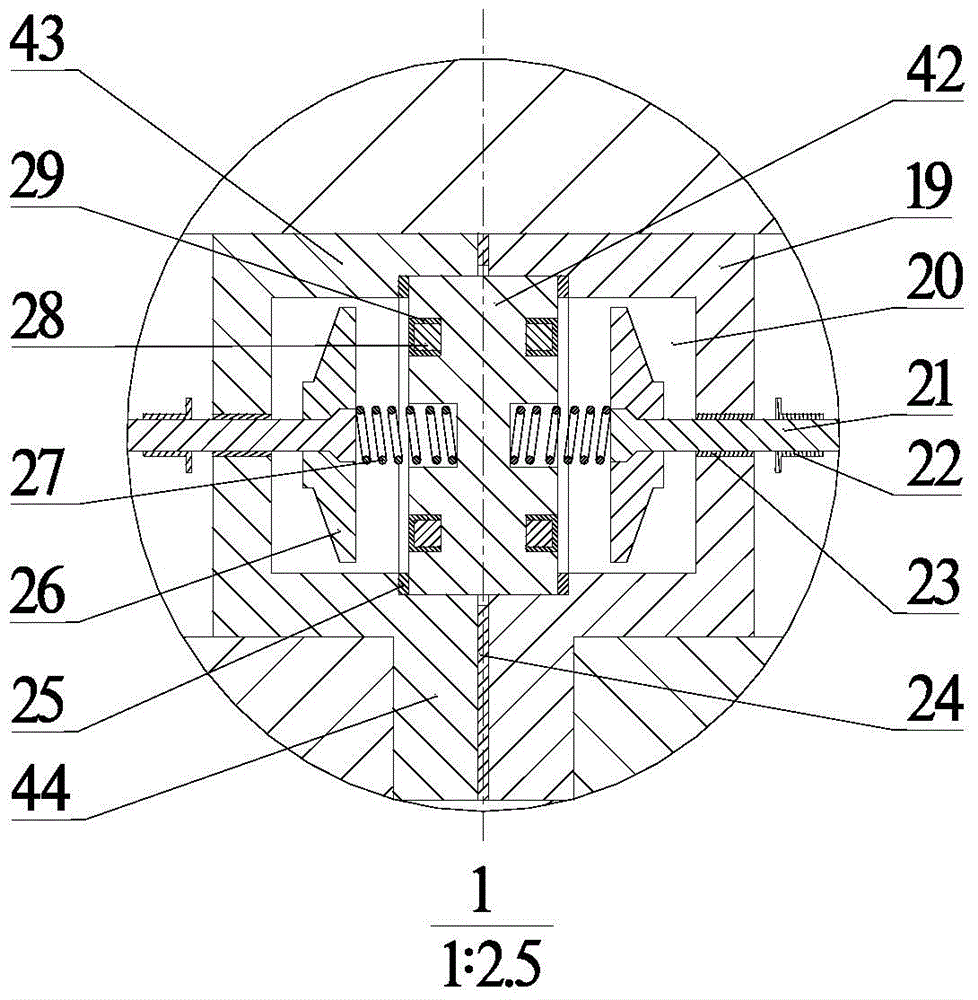

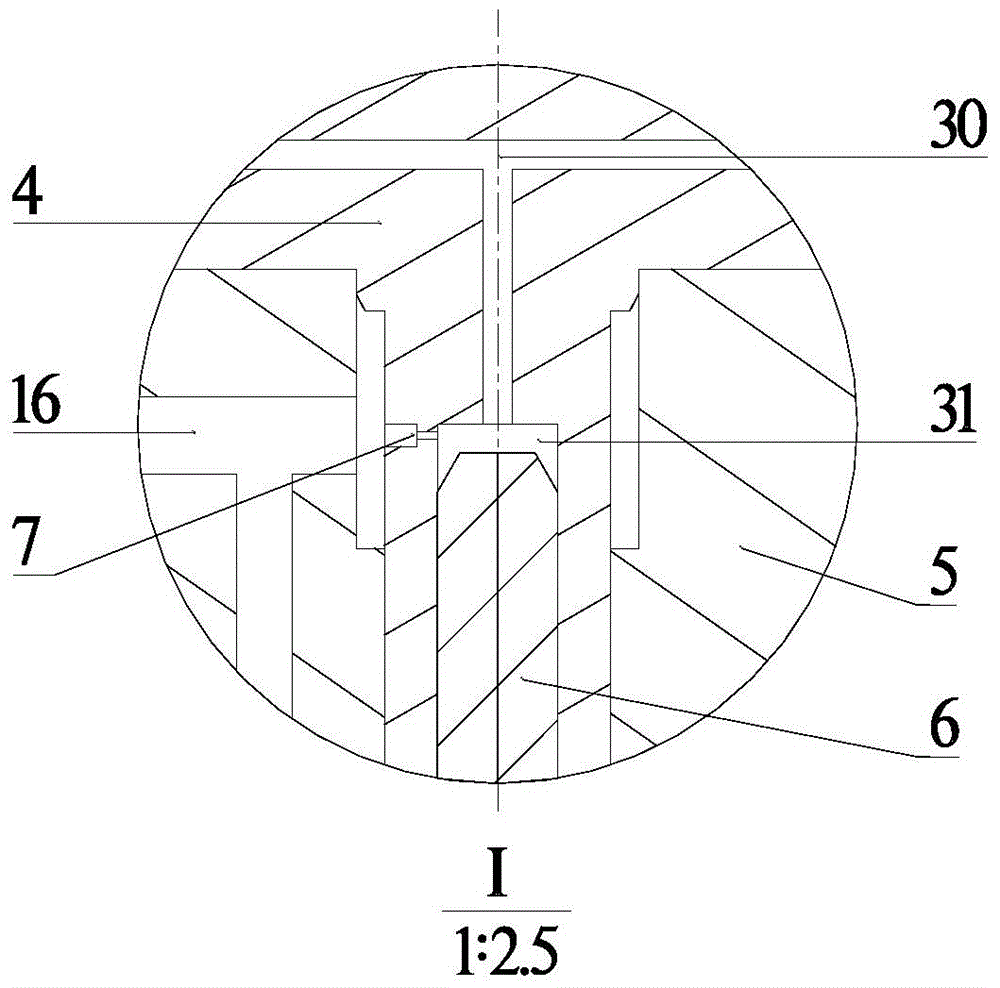

[0034] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0035] combine Figure 1~14. The composition of the first embodiment of the synchronous dual-valve electromagnetic control injector of the present invention includes a synchronous dual-valve electromagnet assembly 1, pilot ball valve seat 2, steel ball 32, control piston body 4, injector body 5, Needle valve ejector rod 6, needle valve return spring seat 8, needle valve return spring 9, nozzle 10, nozzle fastening nut 11, needle valve 12 and injector head fastening nut 18. The needle valve ejector rod 6 and the control piston body 4 are sequentially installed from the upper part of the injector body 5, and the two pilot ball valve seats 2, two steel balls 32 are symmetrically matched with the synchronous double valve electromagnet assembly 1 and placed on the upper part of the control piston body 4, The injector head is fixed by the fastening nut 18, the needle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com