Steel cylinder filling device and method for high-purity arsine

A pure arsine and steel cylinder technology, which is applied in the field of high-purity arsine cylinder filling system, can solve the problems of small output and no high-purity arsine filling system, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

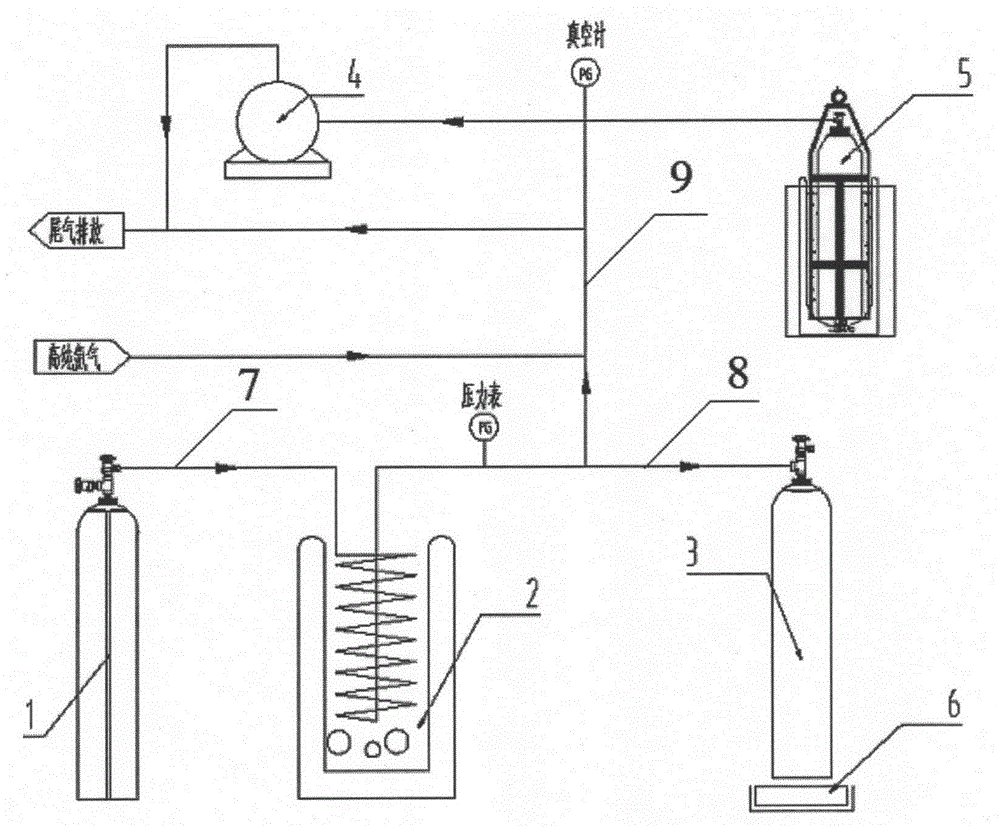

[0025] Such as figure 1 Shown is a schematic structural diagram of a high-purity arsine cylinder filling device. The high-purity arsine cylinder filling device includes a first pipe 7, one end of which is used to connect to the source gas cylinder 1 , The other end of the first pipe 7 is connected to the upper end of the cooling coil, the cooling coil is placed in the cooling tank 2, the lower end of the cooling coil is connected to one end of the second pipe 8, and the other end of the second pipe 8 is used for Connected to the steel cylinder 3 to be filled. The first pipe 7, the cooling coil and the second pipe 8 constitute the main pipe. The second pipe 8 is connected to a branch pipe 9, and the branch pipe 9 is connected to the cold trap collection steel bottle 5. With the vacuum pump 4, the branch pipeline 9 is also connected with a high-purity helium source and a tail gas discharge port. The steel cylinder 3 to be filled is arranged on the steel cylinder scale 6. The co...

Embodiment 2

[0035] Such as figure 1 Shown is a schematic structural diagram of a high-purity arsine cylinder filling device. The high-purity arsine cylinder filling device includes a first pipe 7, one end of which is used to connect to the source gas cylinder 1 , The other end of the first pipe 7 is connected to the upper end of the cooling coil, the cooling coil is placed in the cooling tank 2, the lower end of the cooling coil is connected to one end of the second pipe 8, and the other end of the second pipe 8 is used for Connected to the steel cylinder 3 to be filled. The first pipe 7, the cooling coil and the second pipe 8 constitute the main pipe. The second pipe 8 is connected to a branch pipe 9, and the branch pipe 9 is connected to the cold trap collection steel bottle 5. With the vacuum pump 4, the branch pipeline 9 is also connected with a high-purity helium source and a tail gas discharge port. The steel cylinder 3 to be filled is arranged on the steel cylinder scale 6. The co...

Embodiment 3

[0045] Such as figure 1 Shown is a schematic structural diagram of a high-purity arsine cylinder filling device. The high-purity arsine cylinder filling device includes a first pipe 7, one end of which is used to connect to the source gas cylinder 1 , The other end of the first pipe 7 is connected to the upper end of the cooling coil, the cooling coil is placed in the cooling tank 2, the lower end of the cooling coil is connected to one end of the second pipe 8, and the other end of the second pipe 8 is used for Connected to the steel cylinder 3 to be filled. The first pipe 7, the cooling coil and the second pipe 8 constitute the main pipe. The second pipe 8 is connected to a branch pipe 9, and the branch pipe 9 is connected to the cold trap collection steel bottle 5. With the vacuum pump 4, the branch pipeline 9 is also connected with a high-purity helium source and a tail gas discharge port. The steel cylinder 3 to be filled is arranged on the steel cylinder scale 6. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com