Stirring device achieving internal electromagnetic induction heating function

A stirring device and electromagnetic induction technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as adverse effects of chemical processes, uneven heating of liquids, and slow heating speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

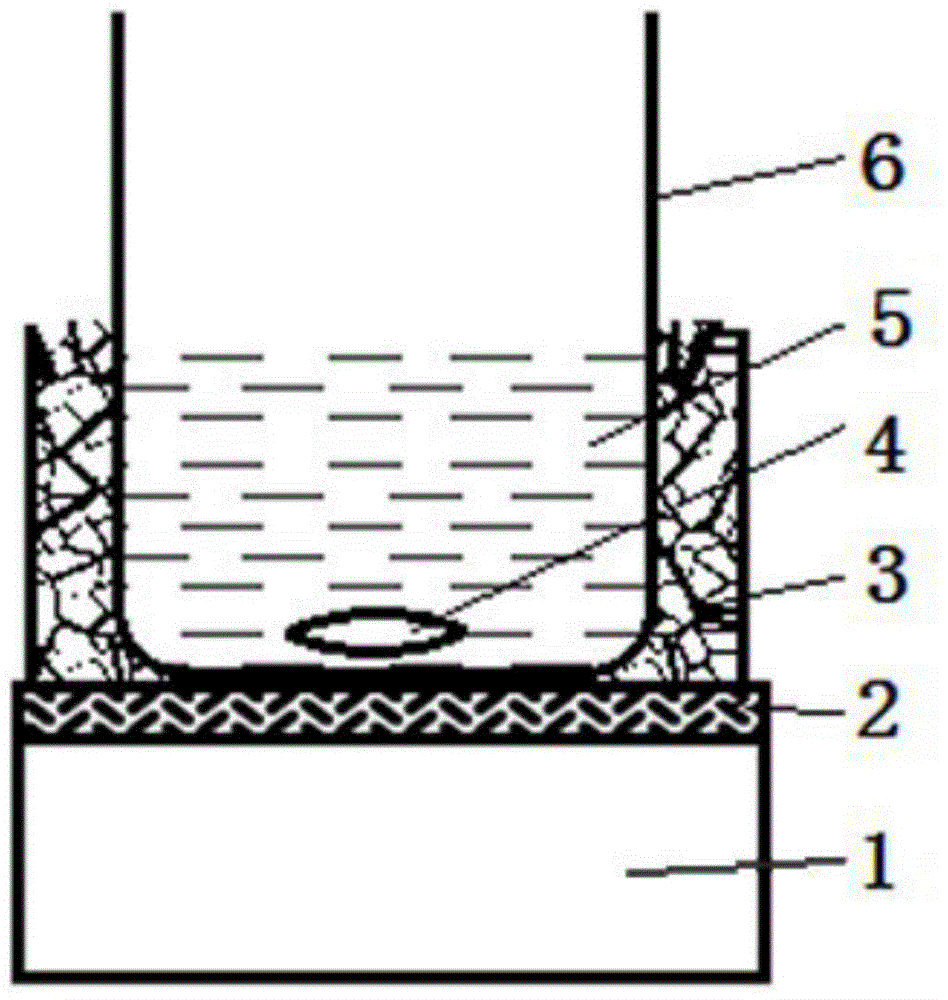

Embodiment 1

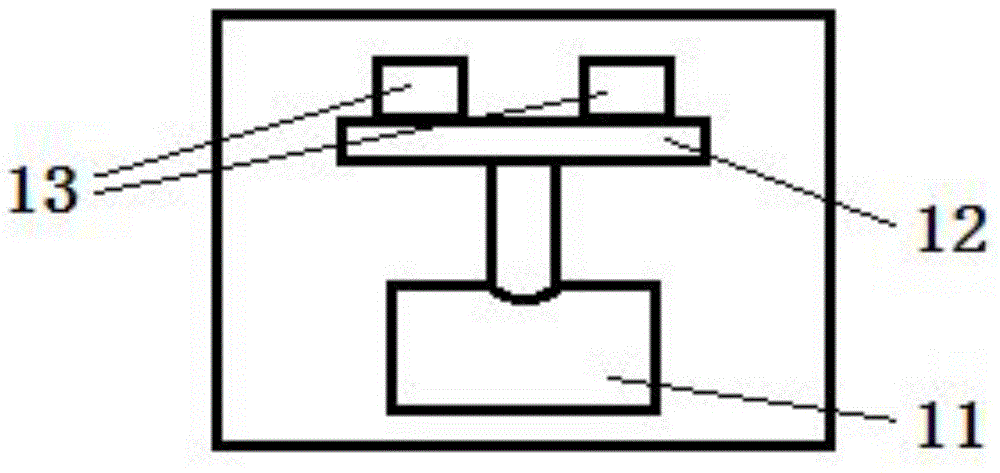

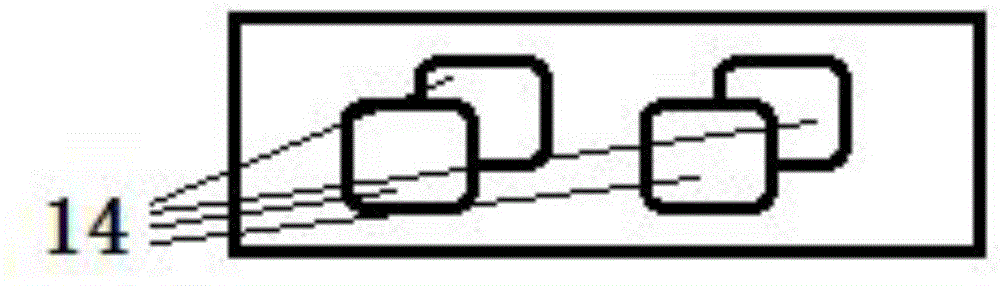

[0038] Embodiment 1 is an electromagnetic internal heating and stirring device using a planar coil, such as Figure 4 As shown, it includes a magnetic field generator 1, a planar coil 71 and a heating magnet 81 with a ring-shaped metal induction sheet. The magnetic field generator 1 adopts a permanent magnet type; the planar coil 71 is placed above the magnetic field generator 1; The heating magnet 81 of the shape metal induction sheet is made up of ring-shaped metal induction sheet 811 and stirring magnet 812, and wherein, ring-shaped metal induction sheet 811 outer diameter is 100mm, is positioned at the outside of stirring magnet 812, and both can be closely combined, It can also be assembled, and the stirring magnet 812 is a permanent magnet, such as Figure 5 shown. The ring-shaped metal induction piece 811 can be made of ferromagnetic metal, such as steel, iron, cobalt, nickel, or non-ferromagnetic metal foil, such as aluminum, copper, silver, molybdenum, tungsten, etc....

Embodiment 2

[0047] Embodiment 2 is an electromagnetic internal heating and stirring device using a cylindrical coil, such as Figure 6 As shown, it includes a magnetic field generator 1, a cylindrical coil 72 and a heating magnet 82 with a cylindrical metal induction sheet. The magnetic field generator 1 adopts an electromagnetic field type; the cylindrical coil 72 is vertically arranged above the magnetic field generator 1, with The heating magnet 82 of the cylindrical metal induction sheet is made up of the cylindrical metal induction sheet 821 and the stirring magnet 822. The outer diameter of the cylindrical metal induction sheet 821 is 20 mm and is located outside the stirring magnet 822. The two can be closely combined, or It can be assembled, and the stirring magnet 822 is a permanent magnet, such as Figure 7 shown. The material of the cylindrical metal sensing piece 822 and the material of the outer corrosion-resistant material are shown in the first embodiment.

[0048] During h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com