Orthogonal polarization laser feedback interferometer

An orthogonal polarization and laser feedback technology, applied in the field of laser measurement, can solve problems such as crosstalk between measurement light and reference light, measurement error, and measurement accuracy reduction, so as to improve stability and anti-interference ability, improve resolution, reduce The effect of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The orthogonally polarized laser feedback interferometer provided by the present invention will be described in detail below with reference to the accompanying drawings.

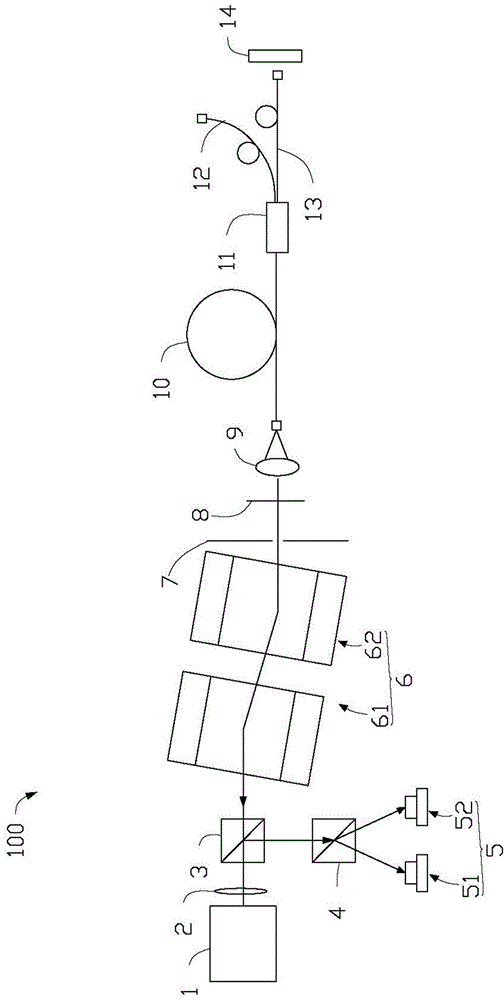

[0015] see figure 1 The orthogonally polarized laser feedback interferometer 100 provided by the embodiment of the present invention includes an orthogonally polarized laser module 1, a focusing lens 2, a beam splitter 3, a polarizing beam splitter 4, a photoelectric detection module 5, and a Optical frequency shifting module 6, a diaphragm 7, a first half-wave plate 8, a polarization coupling lens 9, a first polarization maintaining fiber 10, a fiber polarization beam splitter 11, a second polarization maintaining fiber 12 and a third polarization maintaining optical fiber 13 .

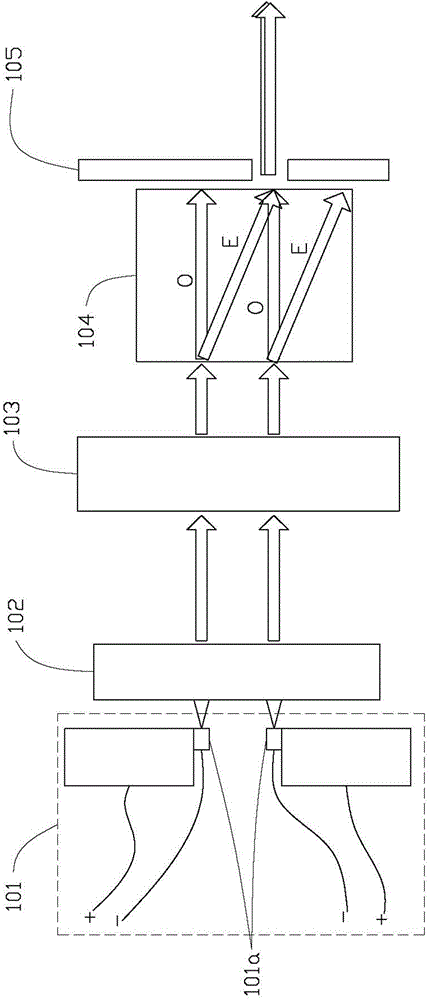

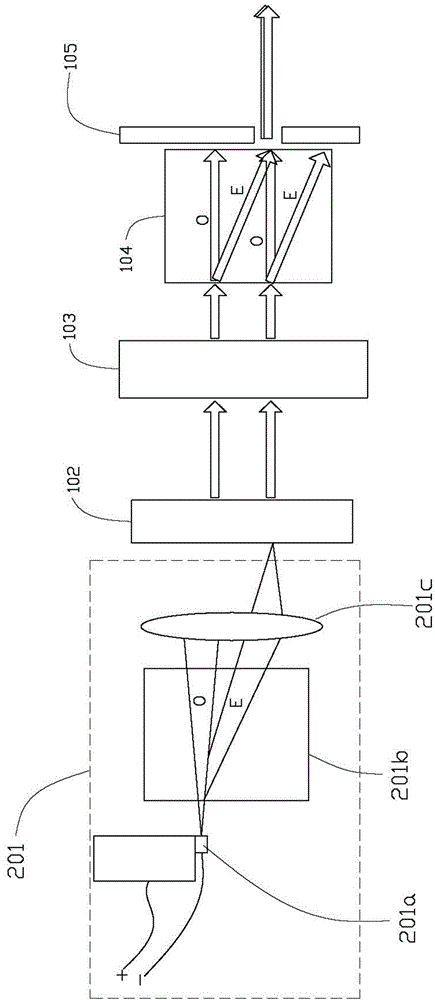

[0016] The orthogonally polarized laser module 1 is used to output two orthogonally polarized laser beams in the same direction, and the two beams of light overlap in space. Please also refer to figure 2 , in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com