Fretting fatigue testing method allowing contact load to be adjusted in real time and testing machine adopting fretting fatigue testing method

A fatigue testing machine, fretting fatigue technology, applied in the testing of mechanical parts, the testing of machine/structural parts, the use of repetitive force/pulse force to test the strength of materials, etc., can solve the problem of low control accuracy and small contact load application range , low degree of automation, etc., to achieve the effect of good repeatability, high test and control accuracy, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] A specific embodiment of the present invention is a fretting fatigue test method with real-time adjustable contact load:

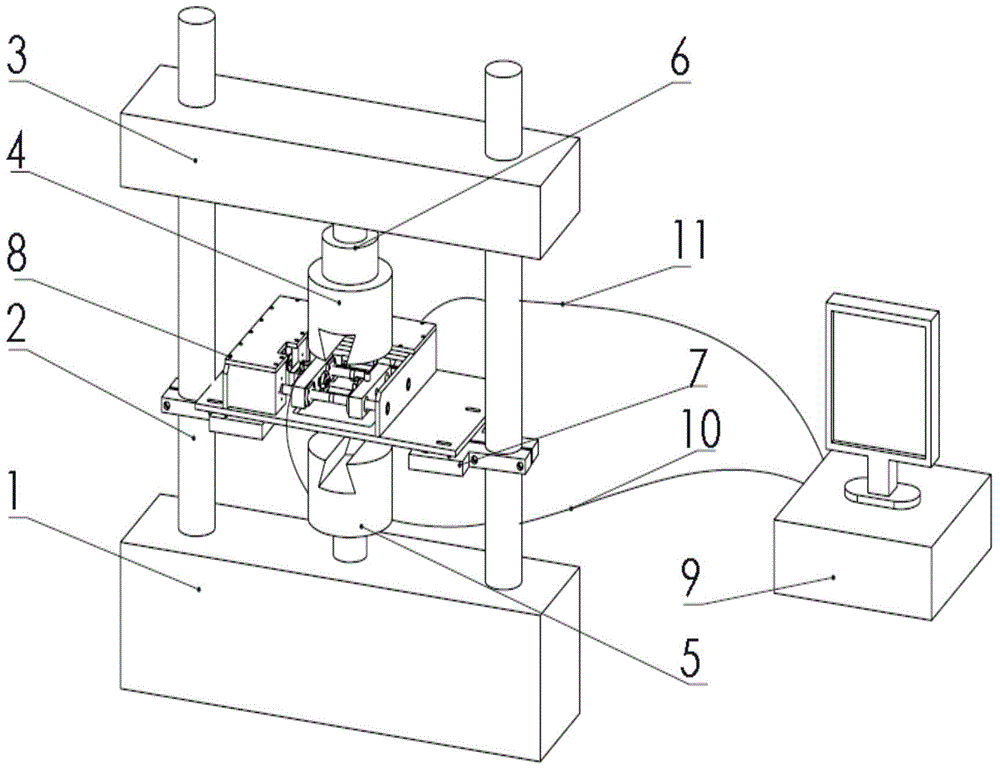

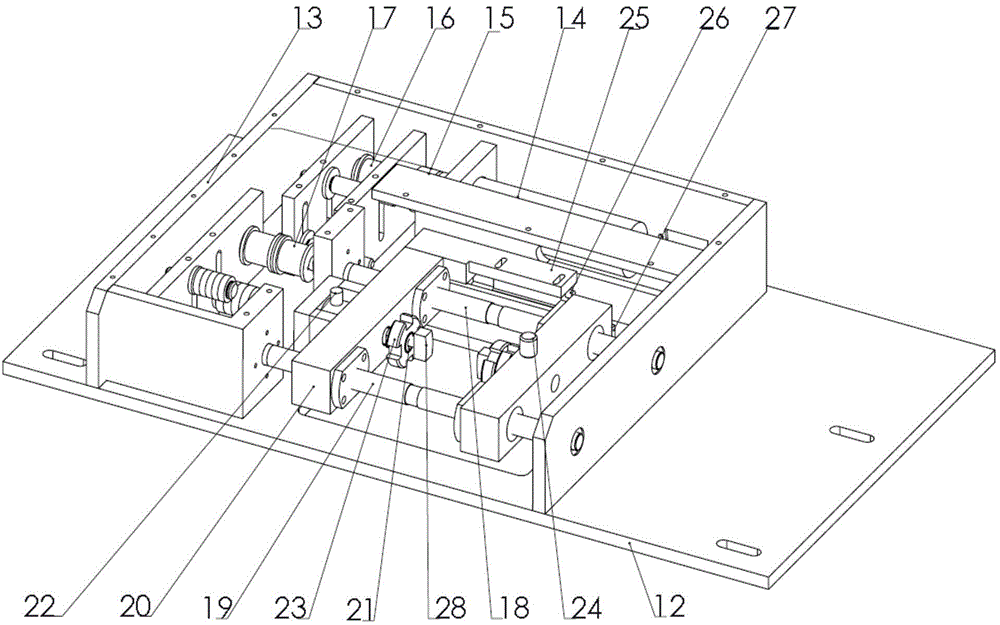

[0045] First, the micro-motion support platform 7 is fixed on the support column 2 of the fatigue testing machine 6 by bolts, while ensuring that the left and right micro-motion support platforms 7 are horizontally aligned; then, the micro-motion device 8 is horizontally placed on the micro-motion support platform 7; Clamp one end of the tested specimen with the upper clamp 4 of the fatigue testing machine 6, and adjust the vertical sliding of the load-bearing beam 3 of the fatigue testing machine 6 and the front, rear, left, and right positions of the micro-movement device 8, so that the front end of the micro-movement pad 28 is in line with the tested specimen. The middle position of the test piece is ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com