A treatment method and treatment equipment for waste gas in wood-based panel industry

A treatment method and treatment equipment technology, applied in the direction of gaseous effluent wastewater treatment, separation method, chemical instrument and method, etc., can solve the problems of large tail gas volume, low organic matter concentration, and unprocessable gas volume in the production of wood-based panels, so as to reduce external waste The amount of pollutants discharged, the obvious environmental benefits, and the effect of improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a treatment method for waste gas from the wood-based panel industry, comprising the following steps:

[0025] (a) The exhaust gas is introduced into the washing tower for spray treatment and then discharged directly to collect the spray liquid;

[0026] (b) After filtering the spray liquid, let it stand for stratification to obtain the first supernatant and the first precipitate;

[0027] (c) aerating and regenerating the first supernatant to degrade and remove the organic matter therein, and then standing and stratifying to obtain the second supernatant and the second precipitation;

[0028] (d) collecting the first precipitate and the second precipitate, and draining the second supernatant;

[0029] (e) pump part of the second supernatant into the washing tower for recycling, change the process of spraying and absorbing with pure water or activated sludge, and spray with a circulating liquid rich in extracellular polymers, It greatly improve...

Embodiment 2

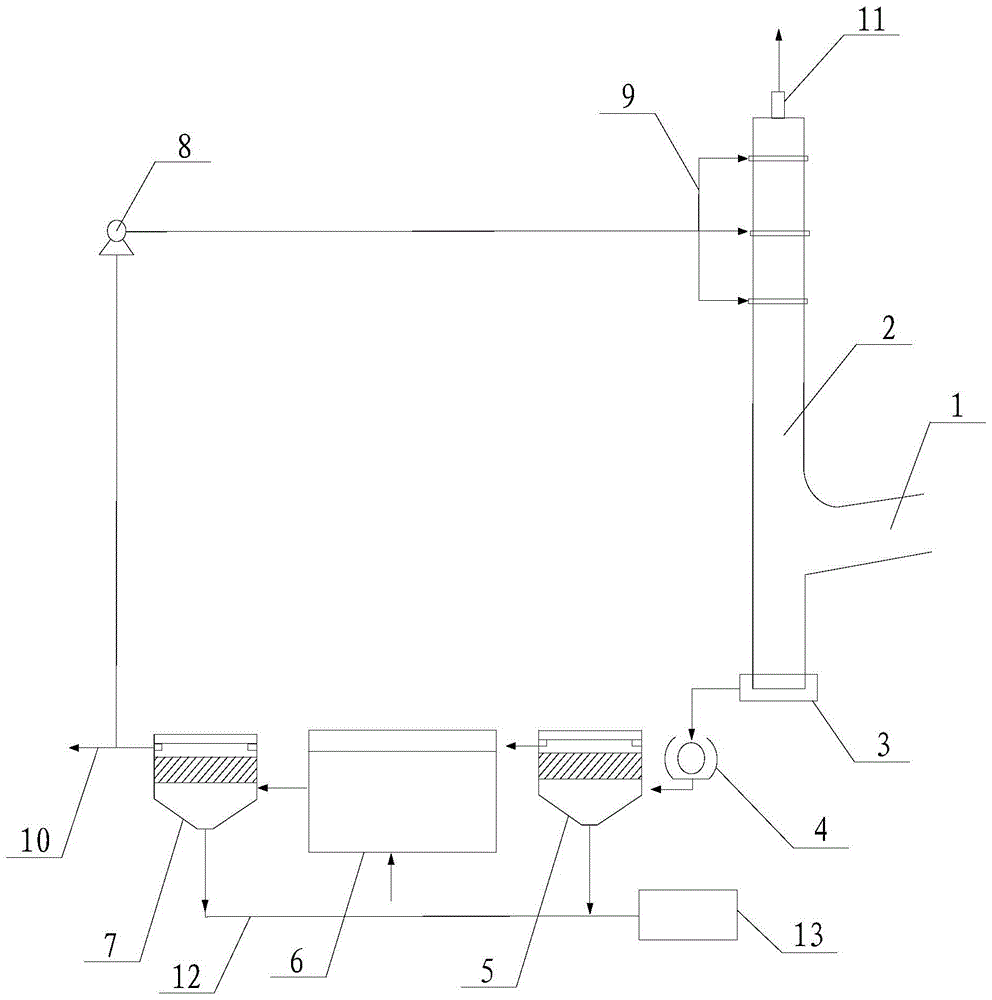

[0032] Such as figure 1 As shown, this embodiment provides a treatment equipment for waste gas in the wood-based panel industry, which mainly includes an air guide pipe 1, a washing tower 2, a collection pipe 3, a microfilter 4, a first sedimentation tank 5, a biological regeneration tank 6 and a second sedimentation tank Pool 7 and other components.

[0033] Wherein, the lower part of the washing tower 2 communicates with the air duct 1, and a dust sensor can be installed in the washing tower 2 for measuring the concentration and particle size of the dust. The collecting pipe 3 is installed at the lower end of the washing tower 2 for collecting the spray liquid sprayed out from the washing tower 2 . The microfilter 4 communicates with the collecting pipe 3 and is used to filter and remove most of the suspended matter in the spray liquid. The first settling tank 5 is connected with the microfilter 4 to remove the remaining suspended matter in the spray liquid after precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com