Full mold casting molten iron introducing type chill

A solid type casting and introduction technology, which is applied in casting molding equipment, molds, cores, etc., can solve problems such as shrinkage porosity defects and chilling effect, and achieve the effects of convenient clamping, good effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

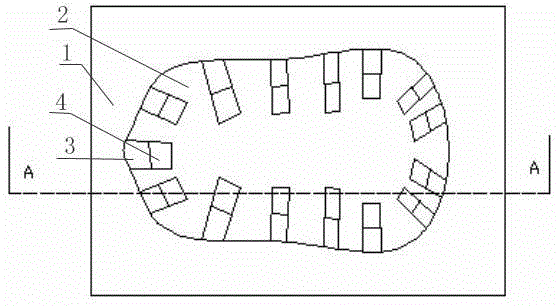

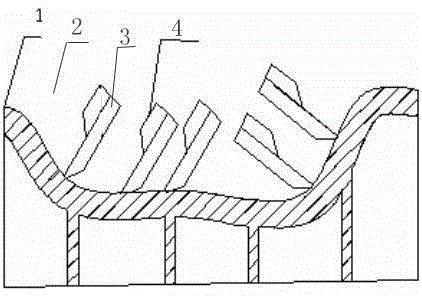

[0013] The present invention as figure 1 , 2 shown.

[0014] The full mold casting molten iron lead-in chiller includes casting a real mold 1, and a plurality of polystyrene foam strips 3 are arranged in the molding sand 2 of the inner curved surface of the casting solid mold 1, and pig iron blocks 4 are pressed on the middle and upper parts of the polystyrene foam strips 3 , the polystyrene foam strip 3 is seamlessly connected with the casting solid mold 1, and the polystyrene foam strip 3 can become a cast iron strip after pouring.

[0015] The polystyrene foam strips 3 are 200-400mm long, 30-100mm wide, and 10-30mm thick, and are distributed in the molding sand 2 at an inclined array spacing of 30-150mm, with an installation inclination angle of 5-45°.

[0016] The angle of the included angle of the inner curved surface of casting real mold 1 is 15-120°.

[0017] The present invention has good experimental effect on complex curved surfaces of automobile molds. The surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com