A kind of preparation method of aluminum-titanium-boron alloy rod

A technology of aluminum-titanium-boron and alloy rods, which is applied in the field of preparation of aluminum-titanium-boron alloy rods, can solve the problem of inconvenient use of powdery refiners, the inability to meet the semi-continuous casting and continuous casting and rolling production of pure aluminum and aluminum alloys, and no Involving aluminum-titanium-boron alloy rods and other issues, to achieve the effect of small size, fine grain structure, and avoid trachoma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

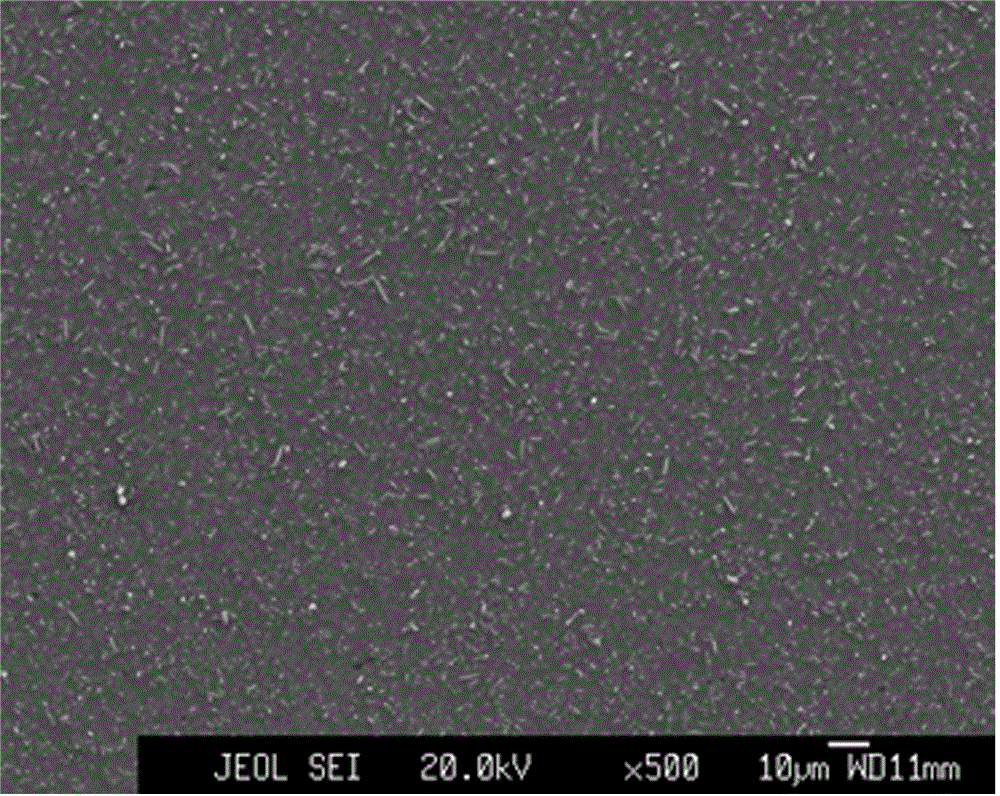

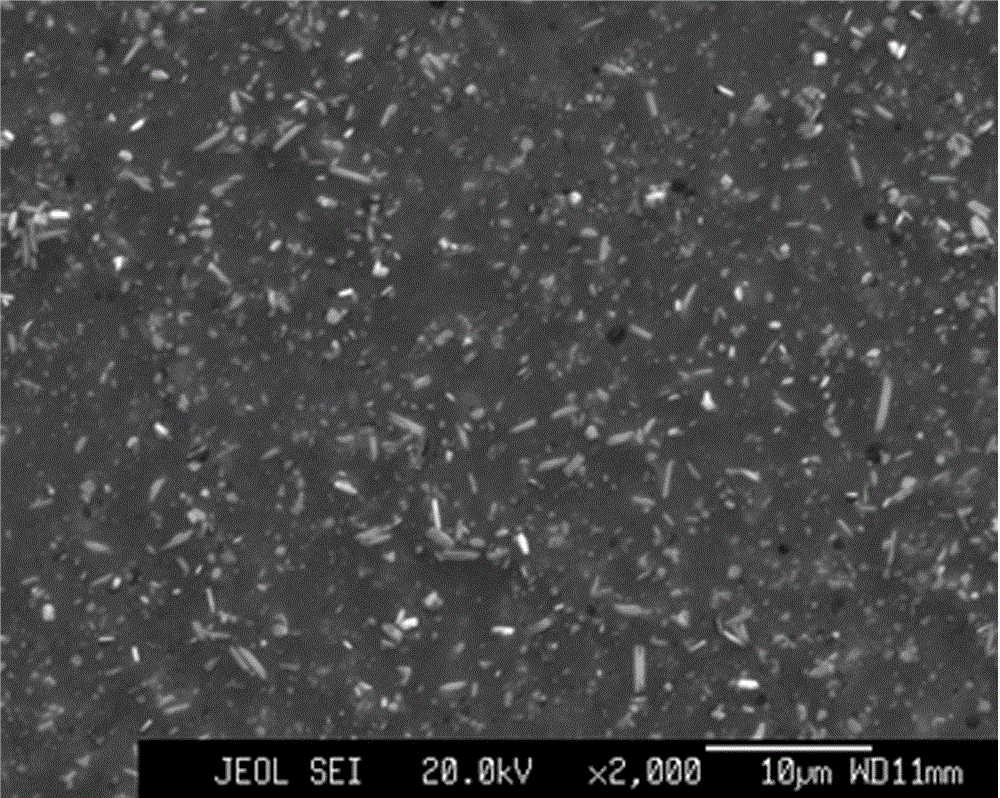

[0035] The aluminum-titanium-boron alloy rod with 5% Ti element content and 1% B element content is prepared by adopting the present invention. The main equipment is an intermediate frequency induction melting furnace, an atomizing powder mill, a vibration screening machine, a cold isostatic press and a horizontal type Extruder, the preparation method is as follows:

[0036] Step 1: Heat and melt the aluminum ingot in an intermediate frequency induction furnace and increase the temperature to 875°C, then add 25% potassium fluorotitanate and 11.5% potassium fluoroborate to the aluminum ingot. After stirring for 80 minutes, remove the surface of the alloy liquid Dross to obtain aluminum titanium boron alloy liquid;

[0037] The second step: transfer the aluminum-titanium-boron alloy liquid to the atomizing powder mill, and atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 810℃, and the atomization nitrogen pr...

Embodiment 2

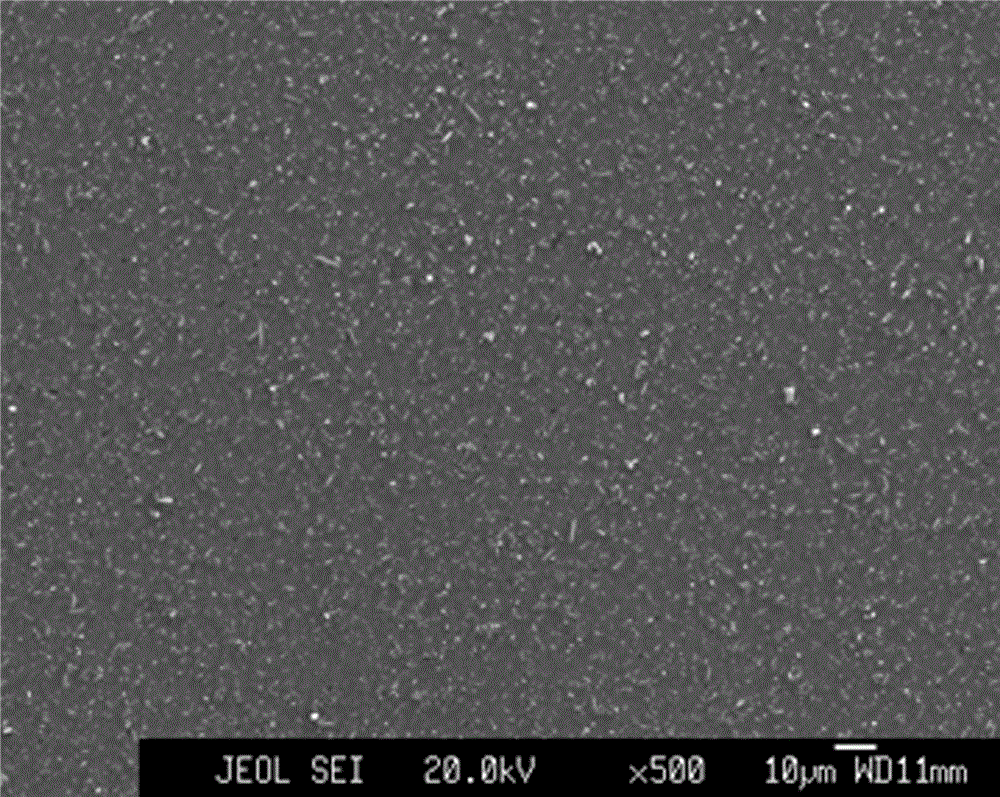

[0051] The aluminum-titanium-boron alloy rod with a Ti element content of 4.5% and a B element content of 0.8% is prepared by adopting the present invention. The main equipment is an intermediate frequency induction melting furnace, an atomizing powder mill, a vibration screening machine, a cold isostatic press and a horizontal type Extruder, the preparation method is as follows:

[0052] Step 1: Heat and melt the aluminum ingot in an intermediate frequency induction furnace and increase the temperature to 850℃, then add 22.5% potassium fluorotitanate and 9.2% potassium fluoroborate, stirring for 60 minutes, remove the surface of the alloy liquid Dross to obtain aluminum titanium boron alloy liquid;

[0053] Step 2: Transfer the aluminum-titanium-boron alloy liquid to the atomizing powder mill, and atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 800℃, and the atomization nitrogen pressure is 2MPa;

[0054]...

Embodiment 3

[0060] The aluminum-titanium-boron alloy rod with a Ti element content of 5.5% and a B element content of 1.2% is prepared by adopting the present invention. The main equipment is an intermediate frequency induction melting furnace, an atomizing powder mill, a vibration screening machine, a cold isostatic press and a horizontal type Extruder, the preparation method is as follows:

[0061] The first step: heat and melt the aluminum ingot in an intermediate frequency induction furnace and raise the temperature to 900℃, then add 27.5% potassium fluorotitanate and 13.7% potassium fluoroborate, stirring for 90 minutes, remove the surface of the alloy liquid Dross to obtain aluminum titanium boron alloy liquid;

[0062] The second step: transfer the aluminum-titanium-boron alloy liquid to the atomizing powder mill, and atomize the aluminum-titanium-boron alloy liquid into powder under the protection of nitrogen, the atomization temperature is 820℃, and the pressure of the atomized nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com