A kind of ti-zr-b grain refiner and its preparation method and application in magnesium alloy

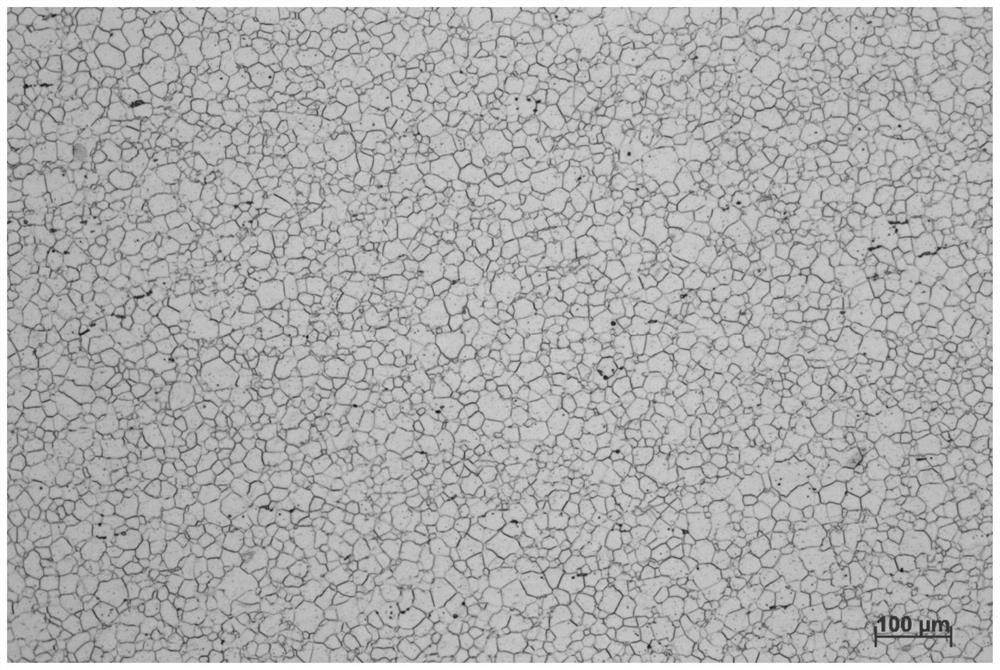

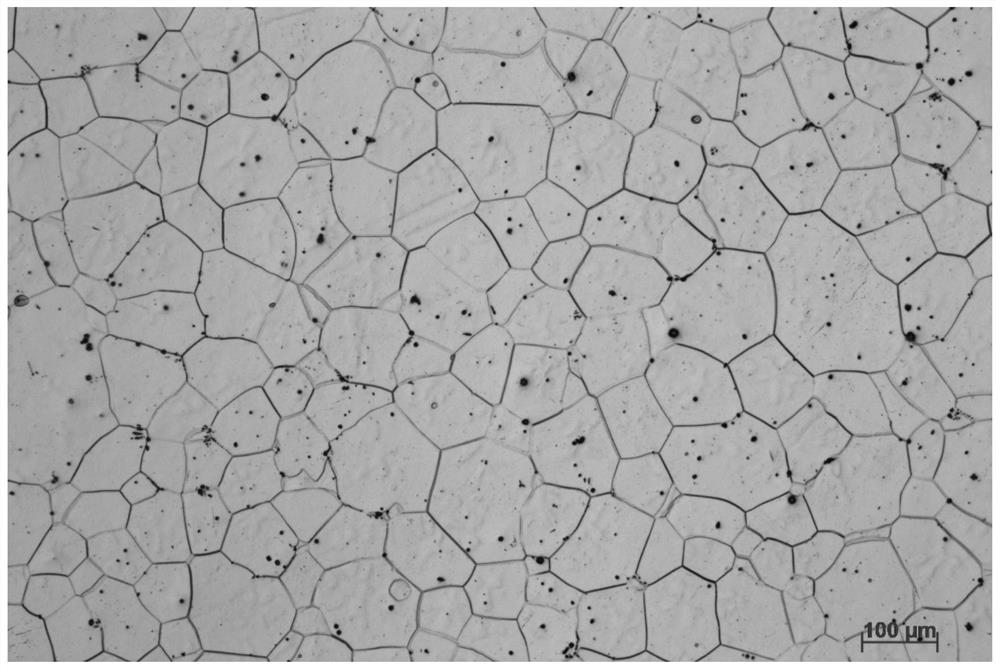

A technology of grain refiner and magnesium alloy, which is applied in the field of metal materials and magnesium alloy grain refinement, can solve the problems of difficult Ti engineering application and low solubility, and achieve uniform microstructure distribution and increased nucleation rate , Improve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the Ti-Zr-B grain refiner whose mass percentage Ti content is 24% and B content is 22% is as follows:

[0033] 1. Select titanium powder and zirconium powder with a particle size of ≤50 microns, and boron powder with a particle size of ≤5 microns as raw materials. After removing the surface oxide scale by a combination of chemical methods and ultrasonic methods, titanium powder, boron powder and zirconium powder Put it into the container in a mass ratio of 24:22:54, add grinding balls, the weight ratio of balls to material is 30:1, seal the container, vacuumize it, and then fill it with high-purity argon gas. Put the sealed container containing the grinding ball into a liquid nitrogen vessel and cool it to -150°C, quickly put it into a planetary ball mill and mix it evenly for 30 minutes. Immerse the container in a liquid nitrogen tank and cool it to -150°C. Repeatedly, the ball mill The rotating speed is 200rpm, and the ball milling time is 4h...

Embodiment 2

[0039] The preparation method of the Ti-Zr-B grain refiner whose mass percentage Ti content is 12% and B content is 19% is as follows:

[0040] 1. Select titanium powder and zirconium powder with a particle size of ≤50 microns, and boron powder with a particle size of ≤5 microns as raw materials. After removing the surface oxide scale by a combination of chemical methods and ultrasonic methods, titanium powder, boron powder and zirconium powder Put it into the container according to the mass ratio of 12:19:69, add grinding balls, the weight ratio of balls to material is 50:1, seal the container, vacuumize it, and then fill it with high-purity argon gas. Put the sealed container containing the grinding balls into a liquid nitrogen vessel and cool to -160°C. Quickly put it into a planetary ball mill and mix evenly for 40 minutes. Immerse the container in a liquid nitrogen tank and cool it to -160°C. Repeatedly, the ball mill The rotating speed is 250rpm, and the ball milling tim...

Embodiment 3

[0046] The preparation method of the Ti-Zr-B grain refiner whose mass percentage Ti content is 25% and B content is 15% is as follows:

[0047] 1. Select titanium powder and zirconium powder with a particle size of ≤50 microns, and boron powder with a particle size of ≤5 microns as raw materials. After removing the surface oxide scale by a combination of chemical methods and ultrasonic methods, titanium powder, boron powder and zirconium powder Put it into the container according to the mass ratio of 25:15:60, add grinding balls, the weight ratio of balls to material is 40:1, seal the container, vacuumize, and then fill with high-purity argon. Put the sealed container containing the grinding ball into a liquid nitrogen vessel and cool it to -140°C, quickly put it into a planetary ball mill and mix evenly for 45 minutes. Immerse the container in a liquid nitrogen tank and cool it to -140°C. Repeatedly, the ball mill The rotating speed is 180rpm, and the ball milling time is 4.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com