A kind of ti-zr-re-mg rare earth magnesium alloy grain refiner and preparation method thereof

A ti-zr-re-mg, grain refiner technology, applied in the field of Ti-Zr-RE-Mg rare earth magnesium alloy grain refiner and its preparation, can solve the problem of affecting the structure and performance of alloys or castings Batch stability, no better, exacerbated problems, etc., to achieve excellent grain refinement ability, improve refinement effect, uniform and fine size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

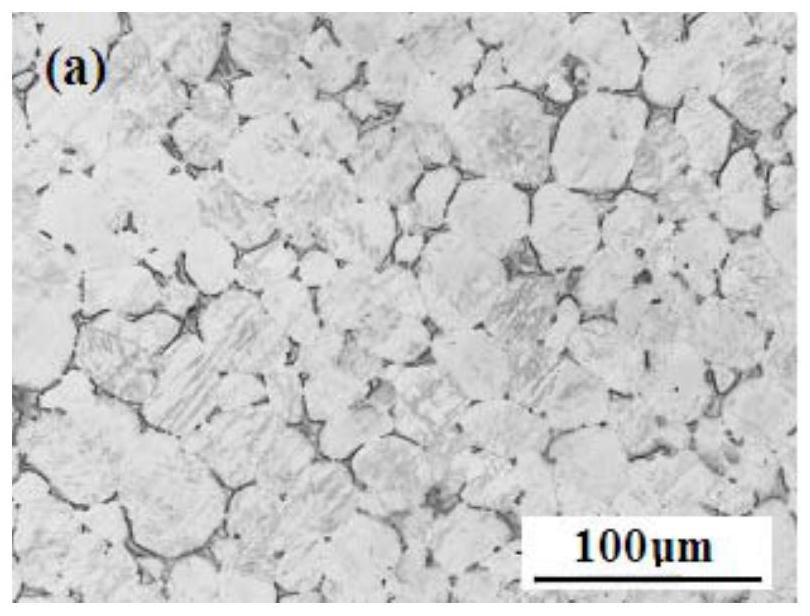

[0034] Preparation of Ti-Zr-RE-Mg grain refiner for refining WE43B magnesium alloy:

[0035] S1, using pure Ti and pure Zr rods as raw materials, preparing the charge according to the mass ratio of 3:2, and using the method of electrode induction melting inert gas atomization to prepare uniformly mixed high-purity Ti-Zr metal powder;

[0036]S2, after crushing pure rare earth Y and pure Mg with a jaw crusher and a ball mill, Y-Mg powder is obtained, and under argon protection, the Y-Mg powder and high-purity Ti-Zr metal powder are combined 1:1 mass ratio immersed in absolute ethanol in a high-energy ball mill jar. Add zirconia ceramic balls, and the ball-to-material ratio is 10:3 (mass ratio); close the ball mill jar. Introduced into argon protective atmosphere, ball milled for 24 hours at a speed of 750 rpm, and the whole process ensures that the tank cooling system always works normally. Transfer the tank to a protective atmosphere, extract the slurry containing Y-Mg powde...

Embodiment 2

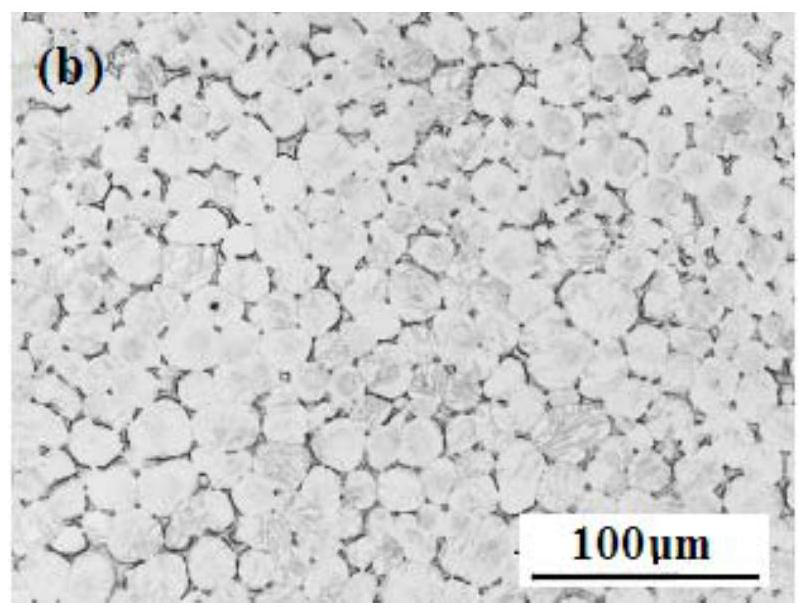

[0040] Preparation of Ti-Zr-RE-Mg grain refiner for refining ZM6 magnesium alloy casing:

[0041] S1, using pure Ti and pure Zr rods as raw materials, preparing the charge according to the mass ratio of 4:3, and using the method of electrode induction melting inert gas atomization to prepare uniformly mixed high-purity Ti-Zr metal powder;

[0042] S2, after crushing pure rare earth Nd and pure Mg with jaw crusher and ball mill, Nd-Mg powder is obtained. Under argon protection, the Nd-Mg powder and high-purity Ti-Zr metal powder are mixed according to The mass ratio of 4:3 is immersed in absolute ethanol in a high-energy ball mill jar. Add zirconia ceramic balls, and the ball-to-material ratio is 10:3 (mass ratio); close the ball mill jar. Introduce argon protective atmosphere, and ball mill for 36h under the condition of rotating speed 500r / min. The whole process ensures that the cooling system of the tank always works normally. Transfer the tank to a protective atmosphere, ...

Embodiment 3

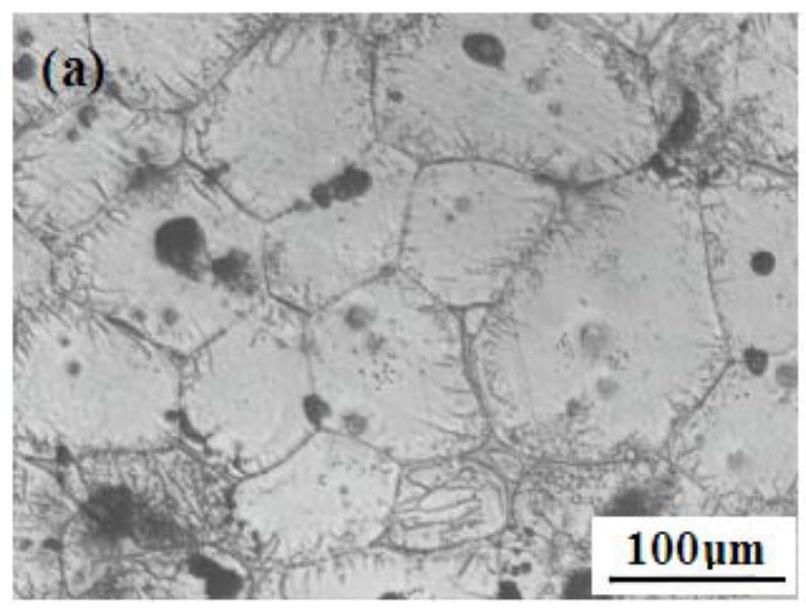

[0046] Grain refiner for a cabin casting of Mg-12Gd-3Y-0.5Zn(VW123Z) magnesium alloy:

[0047] S1, using pure Ti and pure Zr rods as raw materials, preparing the charge according to the mass ratio of 3:5, and using the method of electrode induction melting inert gas atomization to prepare uniformly mixed high-purity Ti-Zr metal powder;

[0048] S2, pure rare earth particles, pure Mg and high-purity Ti-Zr metal powder are immersed in absolute ethanol in a high-energy ball mill in a mass ratio of 3:5. Add zirconia ceramic balls, and the ball-to-material ratio is 10:3 (mass ratio); close the ball mill jar. Introduce argon protective atmosphere, and ball mill for 20h under the condition of rotating speed 800r / min. The whole process ensures that the cooling system of the tank always works normally. Transfer the tank to a protective atmosphere, extract the slurry containing pure RE and Ti-Zr metal powder by filtration, dry and sieve it in an argon protective atmosphere, and store i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com