Laser machining head and laser machining method thereof

A laser processing head and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, limited processing efficiency, and reduced collimation, so as to improve processing efficiency and improve processing efficiency. High and vertical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

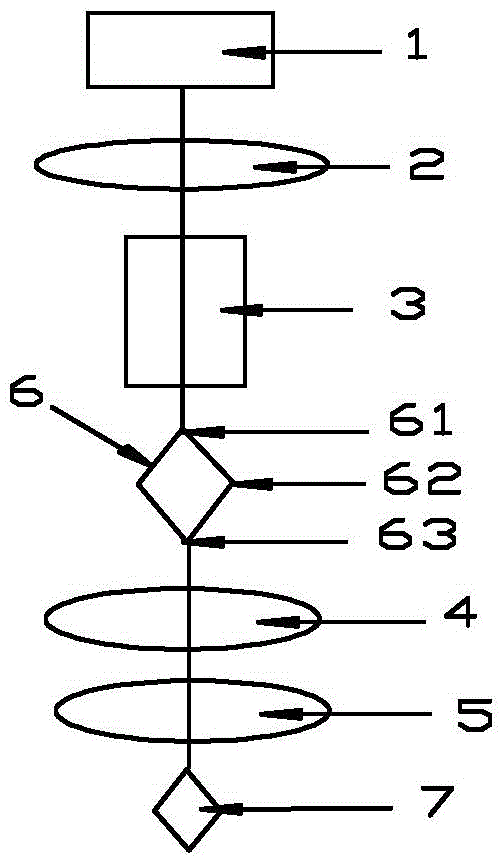

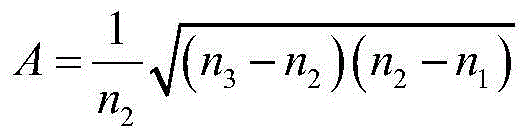

[0028] A laser processing head mainly includes: a laser 1, a focusing lens 2, a biaxial crystal 3 and a zoom system. The zoom system consists of a first convex lens 4 and a second convex lens 5 arranged on a common optical axis, which are arranged in sequence according to the direction of laser transmission: laser 1, focusing lens 2, biaxial crystal 3, first convex lens 4 and second convex lens 5. The focus of the focusing lens 2 is located between the biaxial crystal 3 and the zoom system, the laser output from the laser 1 is parallel to the optical axis of the biaxial crystal 3, and the focusing lens 2 is coated with The film with high transmittance to laser light is coated on the incident surface and exit surface of the biaxial crystal 3, and the film with high transmittance to laser light is coated on the first convex lens 4 and the second convex lens 5. rate film. The biaxial crystal 3 can be rotated to ensure that the converged light beam is parallel to the optical axis...

Embodiment 2

[0052] The same part as embodiment 1 will not be repeated, and the difference is:

[0053] The present invention also provides a method for laser processing using the laser processing head as described above, comprising the following steps:

[0054] (1) After the laser light output by the laser device 1 passes through the focusing lens 2, a converging beam is obtained, and the beam waist radius of the converging beam is ω;

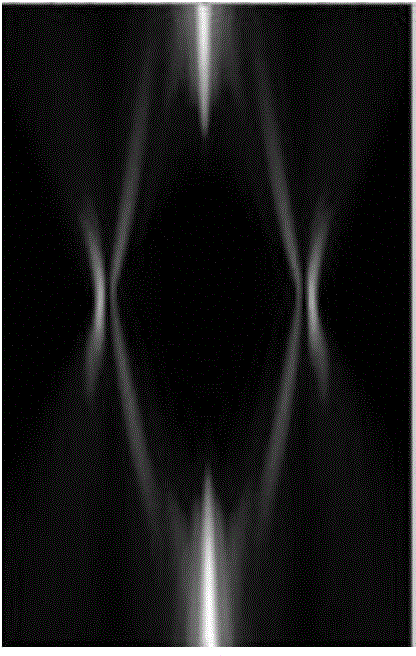

[0055] (2) The converging light beam is incident on the biaxial crystal 3. When it is incident, the converging light beam is parallel to the optical axis of the biaxial crystal 3. After passing through the biaxial crystal 3, a bottle-shaped beam 6 is obtained. The bottle-shaped light beam 6 has a double focus (front Focus 61 and back focus 63), and the focal image plane 63 place is annular;

[0056] (3) Use the focal image plane 62 of the bottle-shaped light beam 6 as the object plane of the zoom system, and use the image plane 7 to punch holes after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com