Glove transferring and stacking manipulator system and glove transferring and stacking method

A technology of manipulators and grasping manipulators, which is applied in the direction of conveyor objects, object stacking, transportation and packaging, etc., can solve the problems of unable to meet the production speed and production process requirements, slow glove transfer speed, low production efficiency, etc., to achieve The working speed is fast, the working environment is pollution-free, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

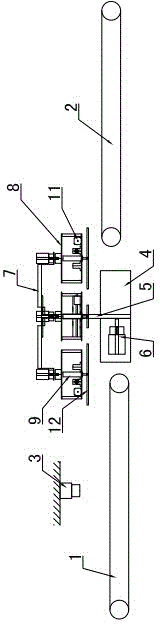

[0027] Embodiment 1, with reference to attached Figure 1-2 : The glove transfer and stacking manipulator system includes a glove feeding belt 1, a glove output belt 2, a visual inspection system 3 and a grabbing manipulator system. A visual inspection system 3 is installed above the glove feeding belt 1, the visual inspection system 3 includes an industrial camera, the direction of the lens of the industrial camera faces the glove feeding belt 1, and the industrial camera is connected to the control system through a data line. A grabbing manipulator system is installed between the glove feeding belt 1 and the glove output belt 2, and the grabbing manipulator system is connected to the control system, and the control system adopts a PLC programmable control system.

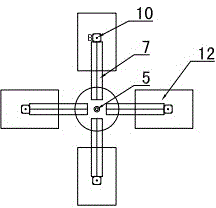

[0028] The grasping manipulator system includes a supporting rotating device, and a plurality of grasping devices rotating with the supporting rotating device as the axis are installed on the upper part of the sup...

Embodiment 2

[0037] Embodiment 2, the grasping device is provided with three evenly distributed around the circumference, and the angle between each is 120°. When using the glove transfer and code stack manipulator system to transfer the code stack, in step d, the main motor 6 drives The rotating shaft 5 rotates 120°, and the glove suction cup 12 rotates 120° at the same time to put down the glove for coding. The rest of the settings are the same as in Example 1.

[0038] In the above-mentioned embodiments, according to actual needs, the grasping devices can also be set to two or more other numbers evenly distributed around the circumference.

[0039] The glove transfer and stacking manipulator system can also use electrostatic adsorption to absorb gloves. At this time, there is no need to provide an air suction hole in the glove suction cup 12, and the glove suction cup 12 is equipped with a static electricity generating device that can generate static electricity in the lower part, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com