Hot slag stone materialization system and process

A technology for hot slag and melting subsystem, which is applied in the field of hot slag recycling, can solve the problem of no blast furnace slag stone formation, and achieve the effects of reducing brittleness, reducing supplementary heat, and using less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

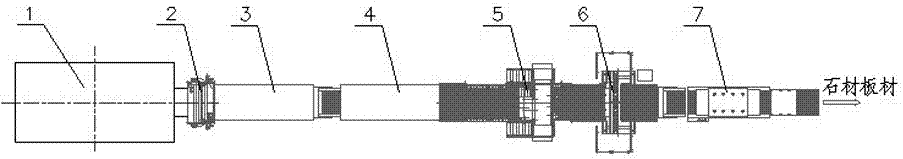

[0046] This embodiment provides a hot slag lithification system, which includes a melting subsystem, a calendering device, a heat preservation and annealing device, a cutting device, and a packaging device according to the process, and a grinding device can be installed between the cutting device and the packaging device. device, or may not be provided with a grinding device.

[0047] The melting subsystem of this embodiment is connected with the calendering device to introduce the melt into the calendering device, a heat preservation and annealing device is arranged after the calendering device, a cutting device is arranged after the heat preservation and annealing device, and a packaging device is arranged after the cutting device; in addition, A grinding device is arranged between the cutting device and the packing device.

[0048]The above-mentioned melting subsystem is used to make the composition, physical properties and chemical properties of the hot slag meet the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com