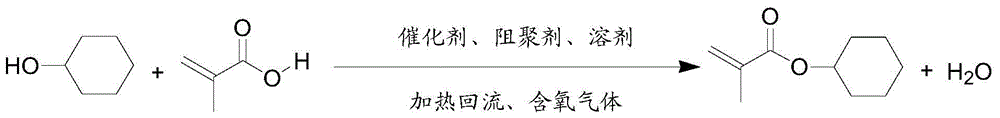

A kind of preparation method of cyclohexyl methacrylate

A technology of methacrylic acid and cyclohexyl ester, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low conversion rate, achieve improved conversion rate, increase conversion rate, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Above-mentioned preparation method comprises the following steps:

[0044] Step (1), adding cyclohexanol, methacrylic acid, solvent, catalyst and polymerization inhibitor to the reactor;

[0045] In step (2), the reaction system obtained in step (1) is heated to a constant temperature after reflux; during the reaction, an oxygen-containing gas is introduced into the reaction system; wherein, the flow rate of the oxygen-containing gas in the late stage of the reaction is greater than that in the early stage of the reaction The flow rate of the oxygen-containing gas, the early stage of the reaction is within 5-8 hours of the beginning of the reaction, and the late stage of the reaction is 5-8 hours after the reaction to the end of the reaction;

[0046] In step (3), after the reaction is completed, the reaction system is cooled, and the cyclohexyl methacrylate product is obtained through neutralization, washing, and vacuum distillation.

[0047]The esterification reactio...

Embodiment 1

[0075] The preparation method of cyclohexyl methacrylate in the present embodiment is as follows:

[0076]Step (1), add 100.0Kg cyclohexanol, 160.0Kg methacrylic acid (the mole of cyclohexanol and methacrylic acid) successively in the reactor that thermometer, water separator, cooling tower, stirring paddle and ventilation pipe are equipped with The ratio is 1:1.8), 64.0Kg cyclohexane, 4.05Kg solid superacid 4.05Kg p-toluenesulfonic acid, 1.725Kg p-hydroxyanisole, 3.61Kg hypophosphorous acid, and add 41.6Kg cyclohexane in the water separator.

[0077] Step (2), under the atmosphere of the mixed gas of compressed air and nitrogen (compressed air: nitrogen = 1:2, volume ratio, the same below), turn on the heating device, control the reaction temperature at 70°C to reflux the reaction system; The flow rate is kept at 1.0m in the first 5 to 6 hours of the reaction 3 / h, then keep at 2.0m until the end of the reaction 3 / h; titrate the acid value with KOH standard solution to 9...

Embodiment 2

[0084] The preparation method of cyclohexyl methacrylate in the present embodiment is as follows:

[0085] Step (1), add 100.0Kg cyclohexanol, 110.0Kg methacrylic acid (the mole of cyclohexanol and methacrylic acid) successively in the reactor that thermometer, water separator, cooling tower, stirring paddle and ventilation pipe are equipped with The ratio is 1:1.3), 40.0Kg toluene, 55Kg cyclohexane, 4.05Kg solid superacid 4.05Kg p-toluenesulfonic acid, 1.725Kg copper sulfate pentahydrate, 2.51Kg p-hydroxyanisole, and add 14.2Kg toluene and 27.4Kg cyclohexane into the water separator.

[0086] Step (2), under the atmosphere of the mixed gas of compressed air and nitrogen (compressed air: nitrogen = 1:1.5), turn on the heating device, control the reaction temperature at 60°C to reflux the reaction system, and the flow rate of the mixed gas is within 5 minutes of the beginning of the reaction. ~ 6 hours to maintain at 1.0m 3 / h, then keep at 3.0m until the end of the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com