A method for oxidative desulfurization of oil-complex iron emulsion

A technology for oxidative desulfurization and iron complexation, applied in chemical instruments and methods, separation methods, and sulfur preparation/purification, etc., can solve the problems of tower blockage and foaming that are not completely solved, and achieve no secondary pollution, source Wide range of effects to improve reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of oil-in-water type oil-complex iron emulsion is as follows:

[0044]Based on the quality of the oil-complexed iron emulsion, add 30wt% catalytically cracked diesel oil to the reactor, and add 2wt% emulsifier, wherein the emulsifier type is a composite emulsifier of Span80 and AEO-3 (mass ratio is 48: 52), keep the temperature at 30°C for 5 minutes, then stir at a stirring speed of 300-500r / min, add 68wt% complex iron aqueous solution dropwise, and stir at 30°C for 30 minutes to prepare the oil-in-water oil-complex iron emulsion .

[0045] The present invention is achieved in such a way:

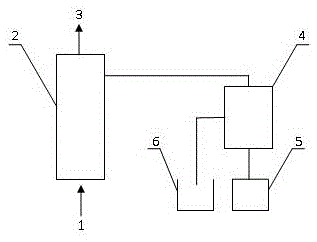

[0046] Contains H 2 S gas 1 enters absorber 2 to contact with oil-complexed iron emulsion, H 2 S is oxidized by complex iron to sulfur, and sulfur dissolves in the surrounding oil phase, releasing H 2 The purified gas 3 of S is discharged from the top of the absorber 2. After the oil-complexed iron emulsion is absorbed and saturated, the oil-complexed iron ...

Embodiment 1

[0050] Removal of H 2 The reaction conditions at S are as follows: In the absorber: the temperature is 50°C, the reaction pressure is 0.5MPa, and the 2 The volume ratio of the hourly flow rate of S gas to the oil-complex iron emulsion is 6:1; in the solid-liquid separator: the temperature for cooling and separating sulfur is 10°C.

[0051] Composition of hydrogen sulfide-containing gas (volume): hydrogen sulfide content is 0.62%, SO 2 COS is 0.01%, and COS is 0.01%. The oil-complexed iron emulsion includes: catalytic diesel oil with a distillation range of 240~260°C, and the Fe ion concentration is 0.06mol / L. Oxidative desulfurization of oil-complexed iron emulsion to purify H in gas 2 S concentration is 10mg / m 3 , the purity of recovered sulfur is 98.5%, demulsification and oil-water separation are carried out every 2 hours, and the absorber is switched at the same time.

Embodiment 2

[0053] Removal of H 2 The reaction conditions at S are as follows: In the absorber: the temperature is 60°C, the reaction pressure is 1MPa, and the 2 The volume ratio of the hourly flow rate of S gas to the oil-complex iron emulsion is 3:1; in the solid-liquid separator: the temperature for cooling and separating sulfur is 5°C.

[0054] Composition of hydrogen sulfide-containing gas (volume): hydrogen sulfide content is 0.18%, SO 2 COS is 0.1%, and COS is 0.03%. The oil-complexed iron emulsion includes: catalytic diesel oil with a distillation range of 260~280°C, and the concentration of Fe ions is 0.08mol / L. After oxidative desulfurization of the desulfurization liquid, the H in the gas is purified 2 S concentration is 6mg / m 3 , the purity of the recovered sulfur is 99.5%, demulsification and oil-water separation are carried out every 3 hours, and the absorber is switched at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com