Preparation method of active large monomers by dehydration and esterification

A technology of active macromonomer, which is applied in the field of preparation of active macromonomer by dehydration esterification, can solve the problems affecting product quality, etc., and achieve high concrete water-reducing rate, high unsaturated bond content, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

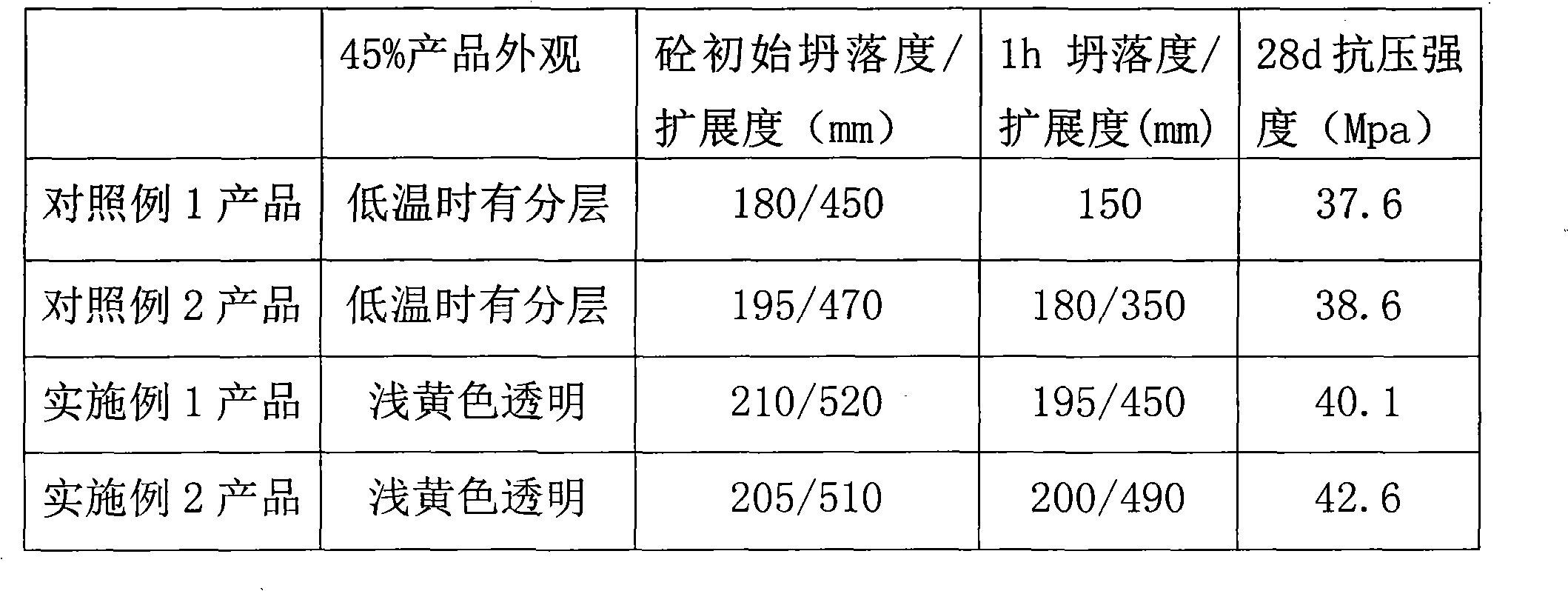

Examples

Embodiment 1

[0018] Feed according to the prescribed order, put methoxypolyethylene glycol and polymerization inhibitor hydroquinone into the reactor and stir for 5-10 minutes, then add methacrylic acid and stir for 3-5 minutes, then inhale the catalyst concentrated sulfuric acid, after the raw materials are fed Start to fill the reactor with nitrogen with a purity of 99.99%, and the filling rate in the first 2.5 hours is 3 to 4m 3 1 bottle of nitrogen gas per hour, the filling flow is 6~8m in the last 3 hours 3 3 bottles of nitrogen gas per hour, after nitrogen filling, heat preservation reaction for 0.5 hours, when the temperature drops below 50°C, add 30% liquid caustic soda with a mass of 0.2-0.5% of the total amount of all materials to neutralize the catalyst, and then mix the ingredients for the next polymerization process.

Embodiment 2

[0020] Put methoxypolyethylene glycol and polymerization inhibitor hydroquinone into the reaction kettle and stir for 5-10 minutes, then add methacrylic acid and stir for 3-5 minutes, then inhale the catalyst concentrated sulfuric acid, and keep the temperature at 120℃±2 After 1.5 hours of esterification reaction at ℃, fill the flow rate of 6~8m within 1 hour 3 / h 1 bottle of nitrogen with a purity of 99.99%, after 0.5 hours of heat preservation reaction, fill it with a flow rate of 6-8m within 2.5 hours 3 3 bottles of nitrogen gas per hour, and keep warm at 120°C±2°C for 0.5 hours. When the temperature drops below 50°C, add 30% liquid caustic soda with a mass of 0.2-0.5% of the total amount of all materials to neutralize the catalyst. The next polymerization process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com