Method for preparing high-purity isobutene from raffinate C4 by means of separation

A technology for raffinating C4 and isobutene is applied in the field of preparation of isobutene, and can solve the problems of low single-pass conversion rate, limited conversion rate, low equipment investment, etc. The effect of selective, simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

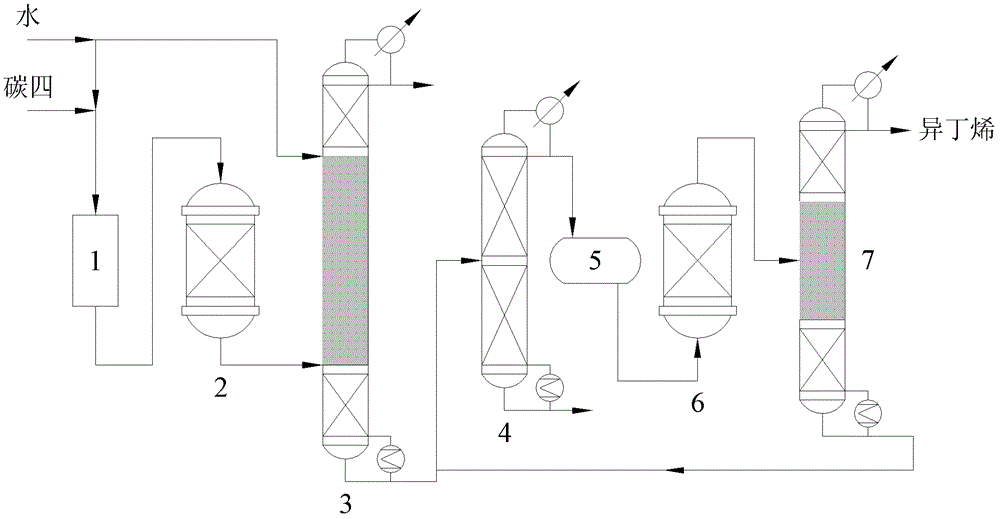

Method used

Image

Examples

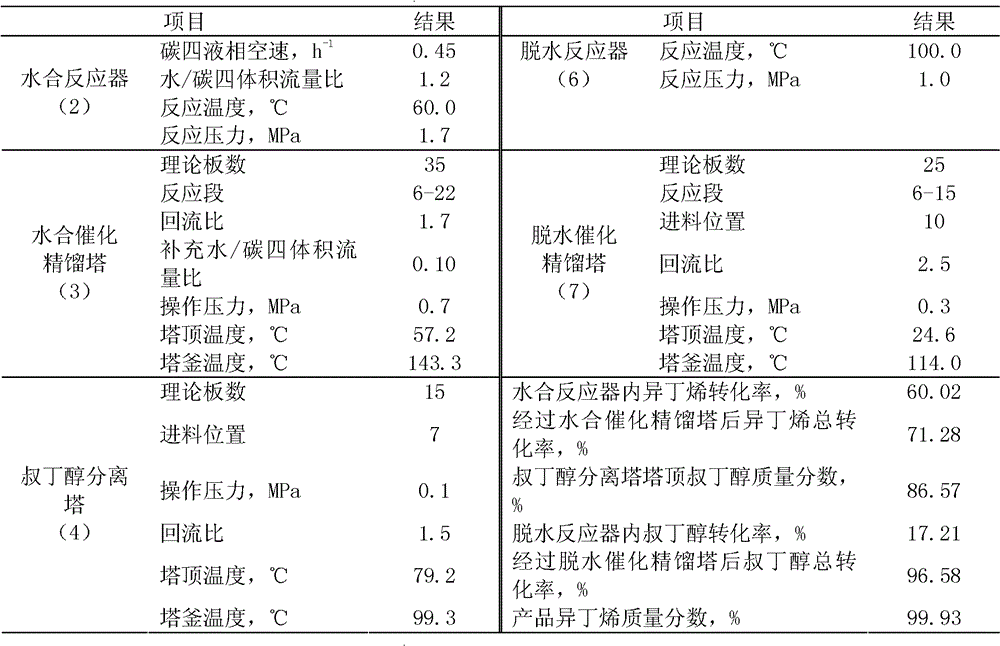

Embodiment 1

[0033] High-purity isobutene is prepared by separating and preparing high-purity isobutene from the by-product C4 fraction of the refinery fluidized catalytic cracking (FCC) unit after extracting butadiene, and the mass percentage content of isobutene in the raffinate C4 is 25.52%. The operating conditions and results are shown in Table 1, and the mass fraction of the product isobutene reaches 99.93%.

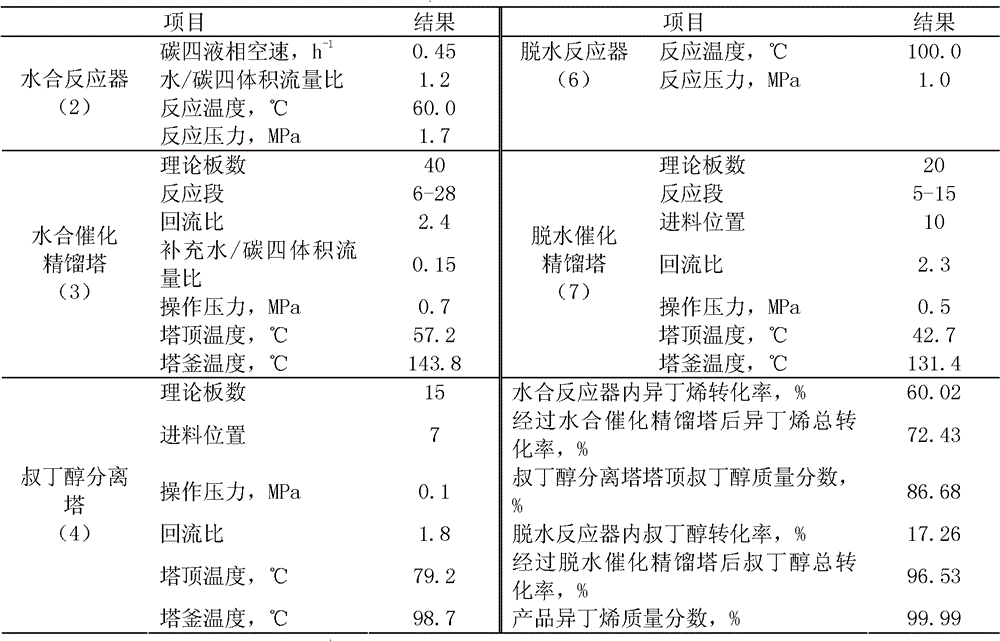

Embodiment 2

[0035] High-purity isobutene is prepared by separating and preparing high-purity isobutene from the by-product C4 fraction of the refinery fluidized catalytic cracking (FCC) unit after extracting butadiene, and the mass percentage content of isobutene in the raffinate C4 is 25.52%. The operating conditions and results are shown in Table 2, and the mass fraction of the product isobutene reaches 99.99%.

Embodiment 3

[0037] High-purity isobutene is separated and prepared by using the by-product C4 fraction of the steam cracking ethylene plant after extracting butadiene as raw material, and the mass percentage content of isobutene in the raffinate C4 is 46.67%. The operating conditions and results are shown in Table 3, and the mass fraction of the product isobutene reaches 99.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com