Production method of diethyl phthalate for flavors and fragrances

A technology of diethyl phthalate and a production method is applied in the production field of diethyl phthalate for flavors and fragrances, and can solve problems such as difficulty of diethyl phthalate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Basic feeding formula

[0027] Phthalic anhydride 12500kg national standard superior product, in line with GB / T15336-2006

[0028] Ethanol 5500kg density is 0.83-0.86g / cm 3 (made by fermenting corn)

[0029] Concentrated sulfuric acid 36kg national standard superior product, in line with GB / T534-2002

[0030] B. Specific operation steps

[0031] 1. Mixing materials: first add ethanol to the mixing tank, the amount of ethanol is 35% of the total ethanol weight, start stirring, if the temperature is too low, use steam to heat up slowly, but the temperature must not exceed 50°C, gradually add 12500kg of phthalic anhydride in the mixing tank. After adding the phthalic anhydride and stirring for 30 minutes, the mixture was transferred to the esterification tank.

[0032] 2. Esterification: After all the mixture is input into the esterification kettle, start stirring, then add 36kg of sulfuric acid, slowly open the steam valve, slowly raise the temperature, fully refl...

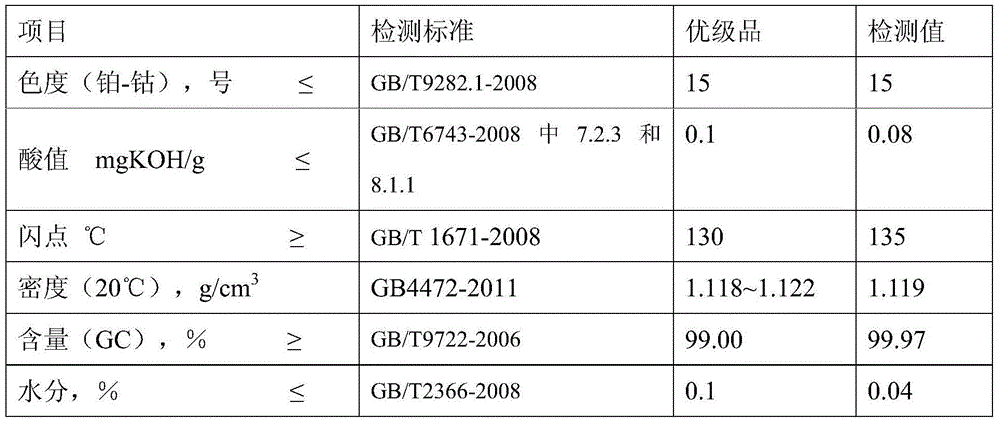

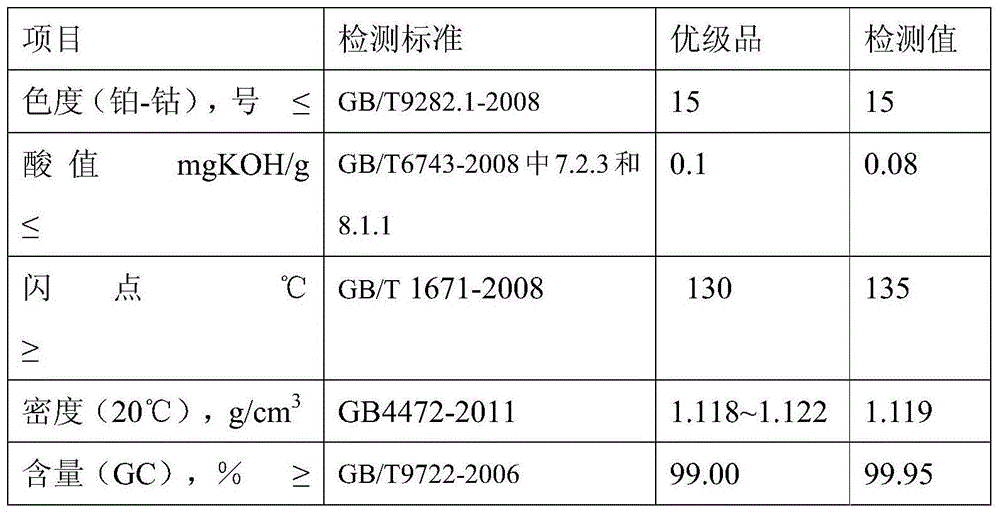

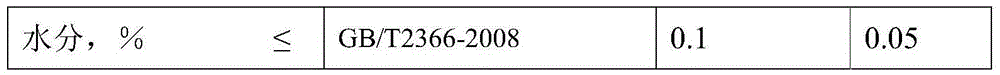

Embodiment 2

[0043] A, the basic formula for feeding

[0044] Phthalic anhydride 12500kg national standard superior product conforms to GB / T15336-2006

[0045]Ethanol 5500kg density is 0.83-0.86g / cm 3 (made by fermenting corn)

[0046] Concentrated sulfuric acid 40kg national standard superior product conforms to GB / T534-2002

[0047] B. Specific operation steps

[0048] 1. Mixing materials: first add ethanol to the mixing tank, the amount of ethanol is 45% of the total ethanol weight, start stirring, if the temperature is too low, use steam to heat up slowly, but the temperature must not exceed 50°C, gradually add 12500kg of phthalic anhydride in the mixing tank. After adding the phthalic anhydride and stirring for 30 minutes, the mixture was transferred to the esterification tank.

[0049] 2. Esterification: After all the mixture is input into the esterification kettle, start stirring, then add 36kg of sulfuric acid, slowly open the steam valve, slowly raise the temperature, fully r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com