Epoxy asphalt mortar and application

A technology of epoxy asphalt and cement, which is applied in building components, building insulation materials, construction, etc., can solve the problems of limiting the scope of use of the cold mix process, wasting the utilization rate of equipment, and unable to store the mixture, and solves the difficulty of production planning and arrangement. , convenient transportation, and the effect of improving the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

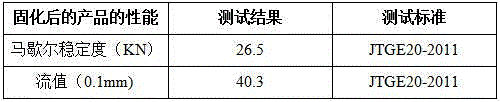

Embodiment 1

[0041] An epoxy asphalt mastic, which is composed of component A of epoxy asphalt resin EP-306 (I), mixed adsorption powder and filler;

[0042] Among them, the mixed adsorption powder is composed of inorganic adsorption powder (diatomite powder, specific surface area: 351cm 2 / g, inside the adsorption powder, with micro-pores and nano-pores) and polymer adsorption powder (tire rubber powder, specific surface area: 809cm 2 / g, the inside of the adsorption powder, which has micro-pores and nano-pores); the inorganic adsorption powder and the polymer adsorption powder account for 5wt% and 25wt% of the epoxy asphalt resin respectively;

[0043] The filler is 20-mesh quartz sand; its dosage is 50wt% of the mass sum of epoxy asphalt resin and mixed adsorption powder.

[0044] The preparation method of the cement is as follows: uniformly mixing raw materials to form a loose cement substance.

[0045] The epoxy mastic was stored at room temperature for one year without any change. ...

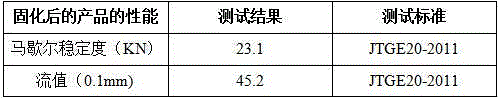

Embodiment 2

[0047] An epoxy asphalt mastic, which is composed of component A of epoxy asphalt resin EP-306 (II), inorganic adsorption powder and filler;

[0048] Among them, the inorganic adsorption powder has a specific surface area of 506 cm 2 / g of ceramic powder (inside the powder, with micro-channels and nano-channels), the dosage is 10wt% of epoxy pitch resin;

[0049] The filler is 20-mesh quartz sand; its dosage is 50wt% of the mass sum of epoxy asphalt resin and inorganic adsorption powder.

[0050] The preparation method of the cement is as follows: uniformly mixing raw materials to form a loose cement substance.

[0051] The epoxy mastic was stored at room temperature for one year without any change.

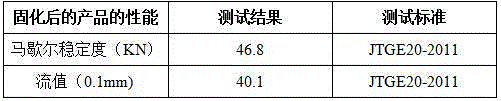

Embodiment 3

[0053] A kind of epoxy asphalt mastic, it is made up of A component of epoxy asphalt resin EP-307, polymer adsorption powder, filler;

[0054] Among them, the polymer adsorption powder has a specific surface area of 632cm 2 / g of tire rubber powder (adsorption inside the powder, with micro-pores and nano-pores), the amount is 50wt% of the epoxy asphalt resin;

[0055] The filler is 20 mesh quartz sand; its dosage is 50wt% of the mass sum of epoxy asphalt resin and polymer adsorption powder;

[0056] The preparation method of the cement is as follows: uniformly mixing raw materials to form a loose cement substance.

[0057] The epoxy mastic was stored at room temperature for one year without any change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com