Hot melt adhesive composition for bookbinding

A composition and hot-melt adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of adhesives sticking to cutters, polluting binding machines, and slow curing of hot-melt adhesives And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

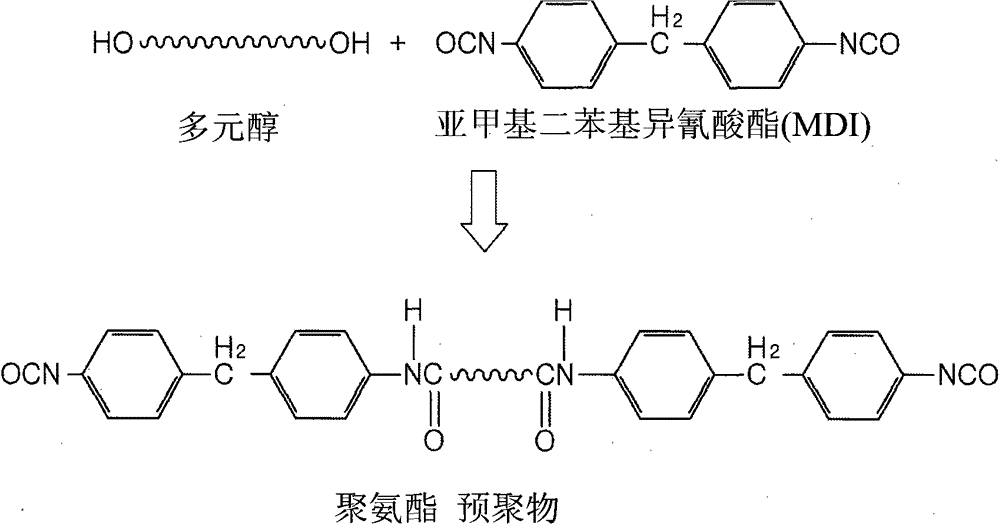

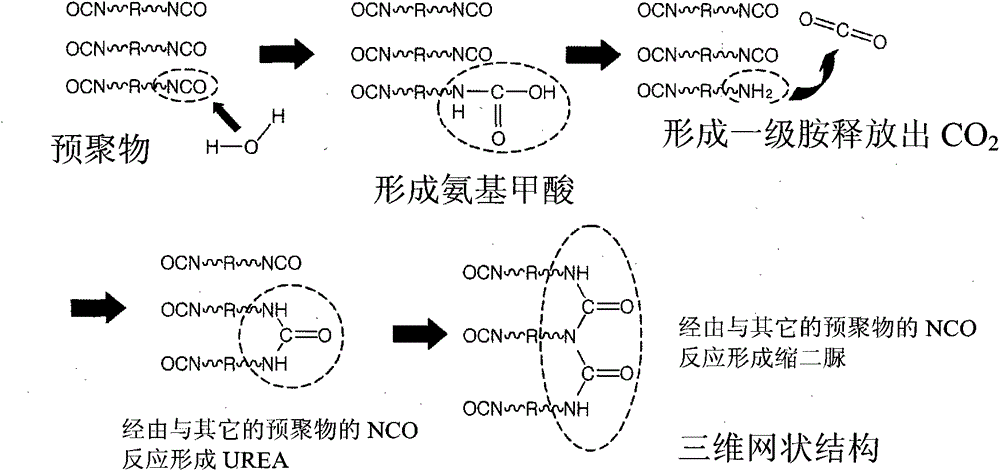

Method used

Image

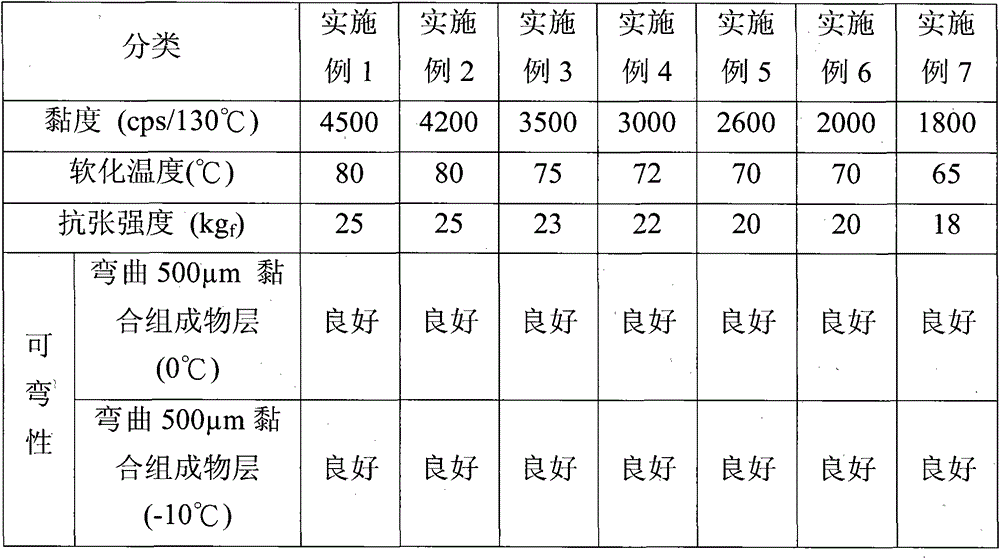

Examples

Embodiment 1

[0046] In the reactor, add 100 parts by weight of polyols, wherein the polyether polyols with a weight average molecular weight of 2000 and the polyester polyols with a weight average molecular weight of 3500 are mixed 1:1 in parts by weight, 20 The styrene-ethylene-butadiene-styrene copolymer of parts by weight, the glyceride of 40 parts by weight, the dipropylene glycol dibenzoate of 4 parts by weight, the calcium oxide of 2 parts by weight, the phenolic antibiotic of 2 parts by weight The oxidizing agent (ANOX-20) and 2 parts by weight of benzophenone were then stirred for 90 minutes while heating the reactor to 120°C. Next, 40 parts by weight of methylene diphenyl isocyanate was added to the stirred mixture, and the mixture was polymerized at 120° C. for 90 minutes. After the polymerization reaction, the bubbles of the polymerization product were removed in a vacuum, and the pressure of the reactor was adjusted at 760 mmHg, thereby preparing a hot-melt adhesive composition...

Embodiment 2

[0048] Except that 35 parts by weight of glyceride and 8 parts by weight of dipropylene glycol dibenzoate were mixed, the method for preparing the hot-melt adhesive composition for bookbinding in Example 2 was the same as that in Example 1.

Embodiment 3

[0050] Except that 30 parts by weight of glyceride and 12 parts by weight of dipropylene glycol dibenzoate were mixed, the method for preparing the hot-melt adhesive composition for bookbinding in Example 3 was the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com