Process for making iron by virtue of COREX furnace

A process and shaft furnace technology, which is applied in the field of ironmaking using COREX furnaces, can solve the problems of low injection volume, small tuyere swirling area, and poor air permeability and liquid permeability of material column, so as to prevent dust pollution and reduce usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

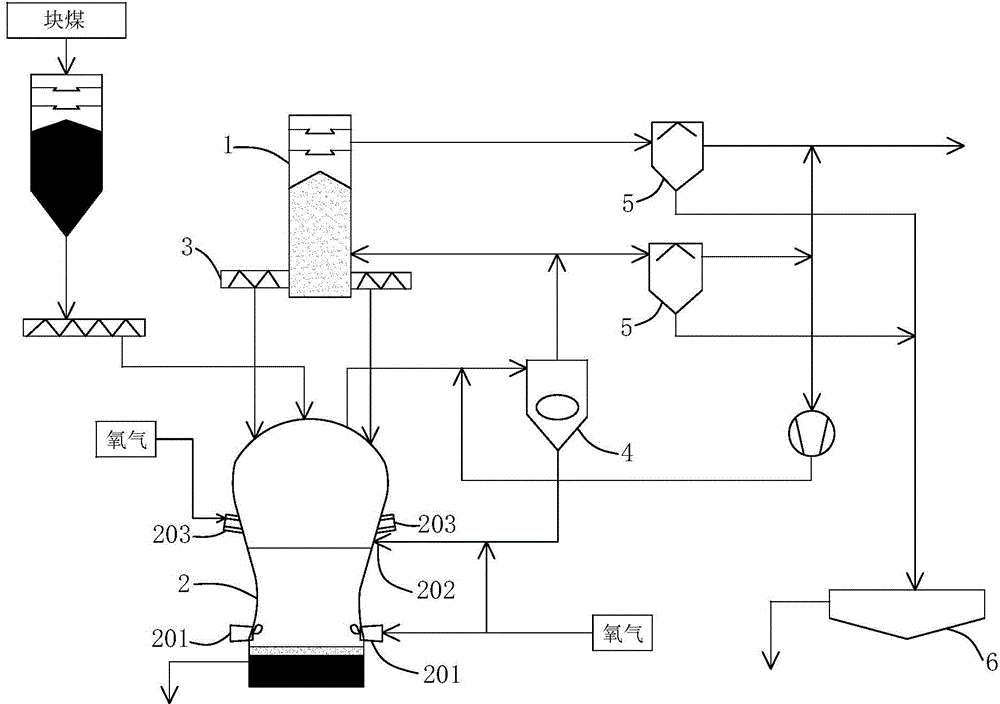

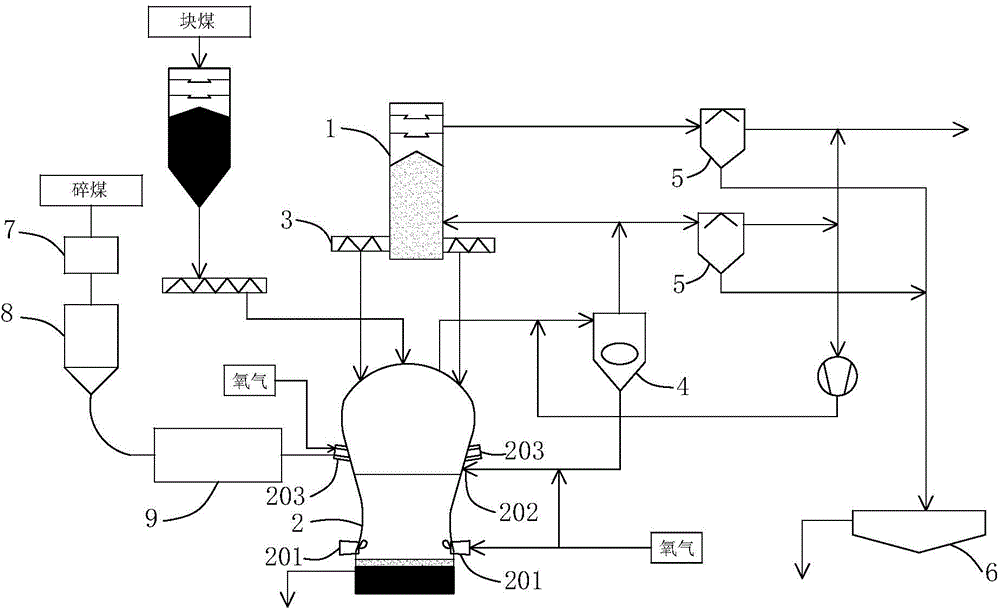

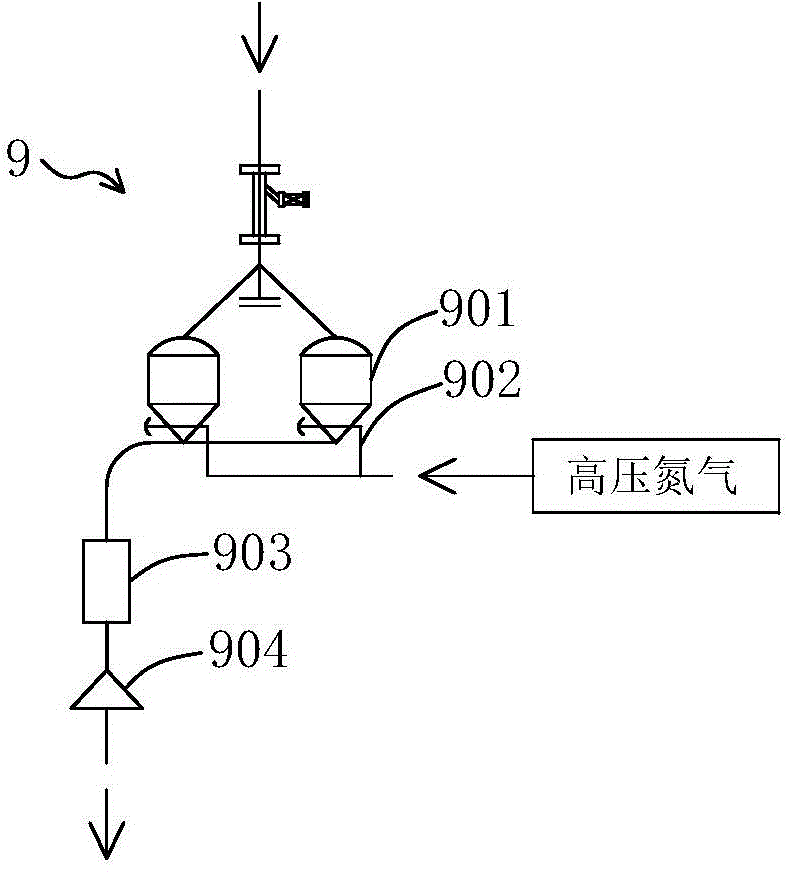

Method used

Image

Examples

Embodiment

[0046] The following table shows the comparison of material consumption under different conditions under the condition of metallization rate of 60% and molten iron hourly output of 150 tons.

[0047] Table 1. COREX theoretical consumption per ton of iron

[0048]

[0049] It can be seen from Table 1 that before this technical solution is implemented, that is, the oxygen burner 203 does not inject coal, according to the material balance and heat balance calculation, it can be known that the ton iron-coke ratio is 250kg, and the fuel ratio is 966kg. But because the excess gas volume is less than 20000NM 3 / h, the factory pressure is difficult to stabilize, and the production operation is difficult (in order to ensure the stability of the factory pressure, the excess gas volume should not be less than 20,000 per hour), which is not feasible. It is necessary to increase the consumption of lump coal to increase the gas volume. Add flux to balance excess heat. Therefore, the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com