Control method of solid solution carbon content in ultra-low carbon bake-hardening steel slabs

A technology of bake hardening and control method, applied in the direction of manufacturing converters, etc., can solve the problems of low hit rate of solid solution carbon content in primary smelting, shorten the smelting time of vacuum refining furnace, and long smelting time, so as to reduce the vacuum refining time, The effect of improving hardening performance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

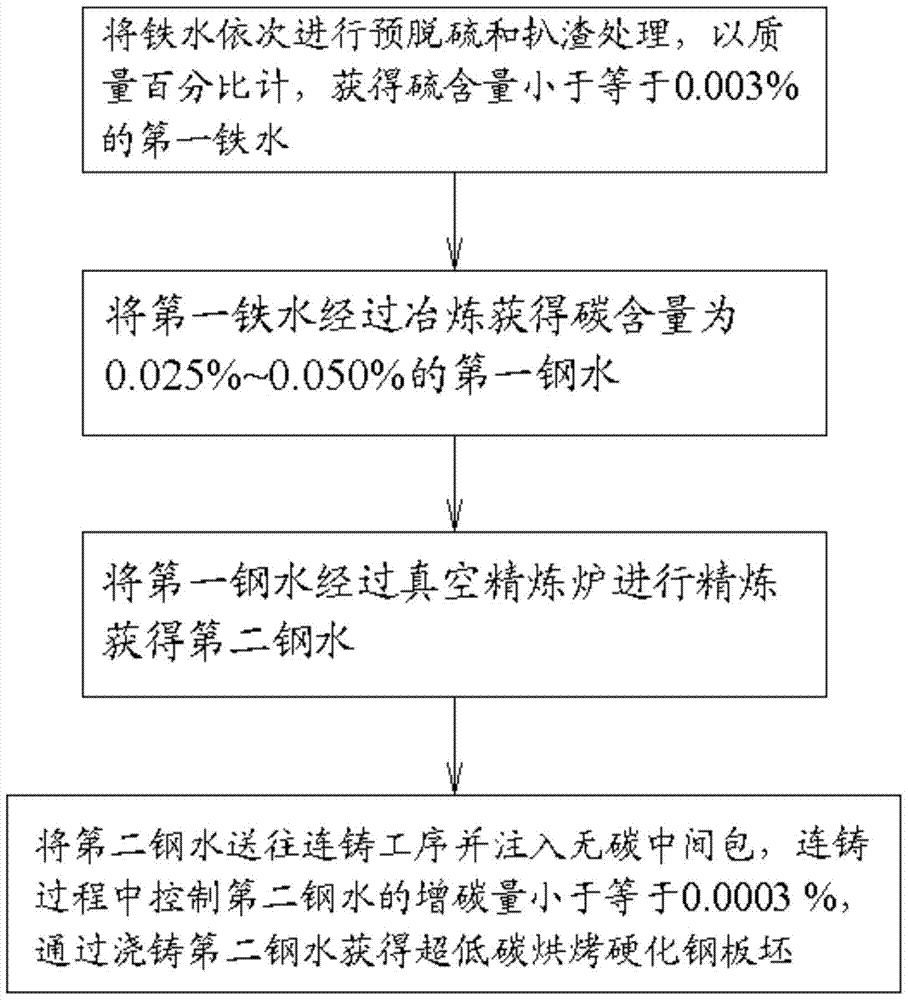

Method used

Image

Examples

Embodiment 1

[0083] The bake-hardening steel CR180BH is produced by using the method for controlling the solid solution carbon content of the ultra-low carbon bake-hardening steel provided by the embodiment of the present invention. The conditions of molten steel entering the RH furnace are C content 0.031%; Si content 0.005%; S content 0.007%; P content 0.031%; Mn content 0.02%; temperature 1625°C; oxygen content 650ppm.

[0084] The temperature and oxygen content are suitable, and no oxygen blowing or scrap addition is required. After refining for 3 minutes, add ferrophosphorus and ferromanganese according to the target P content of 0.036% and target Mn content of 0.35%. 4 minutes after the alloy was mixed, samples were taken to analyze the P and Mn content; the P content was 0.037% and the Mn content was 0.31%; the RH treatment was 15 minutes, and the oxygen value was 425ppm; Enter 60Kg of medium carbon ferromanganese and 13Kg of boron ferroalloy. 21 minutes when the adjustment is com...

Embodiment 2

[0089] The bake-hardening steel CR180BH is produced by using the method for controlling the solid solution carbon content of the ultra-low carbon bake-hardening steel provided by the embodiment of the present invention. The conditions of molten steel entering the RH furnace are C content 0.025%; Si content 0.005%; S content 0.007%; P content 0.031%; Mn content 0.02%; temperature 1646°C; oxygen content 481ppm.

[0090] At the beginning of RH treatment, blow oxygen 30Nm 3 , Add 1.9t of low-carbon steel scrap during the deep decarburization process. After refining for 3 minutes, add ferrophosphorus and ferromanganese according to the target P content of 0.036% and target Mn content of 0.35%. 4 minutes after the alloy was mixed, samples were taken to analyze the P and Mn content; the P content was 0.037% and the Mn content was 0.31%; the RH treatment was 15 minutes, and the oxygen value was 425ppm; Enter 60Kg of medium carbon ferromanganese and 13Kg of boron ferroalloy. 21 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com