Material level detection device and method of straw baler

A technology of material level detection and straw, which is applied in the direction of measuring devices, packaging, liquid level indicators for physical variable measurement, etc., can solve the problems of high maintenance cost, easy error in height, large difference in specific gravity, etc., and achieves simple structure and easy to use Convenience and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

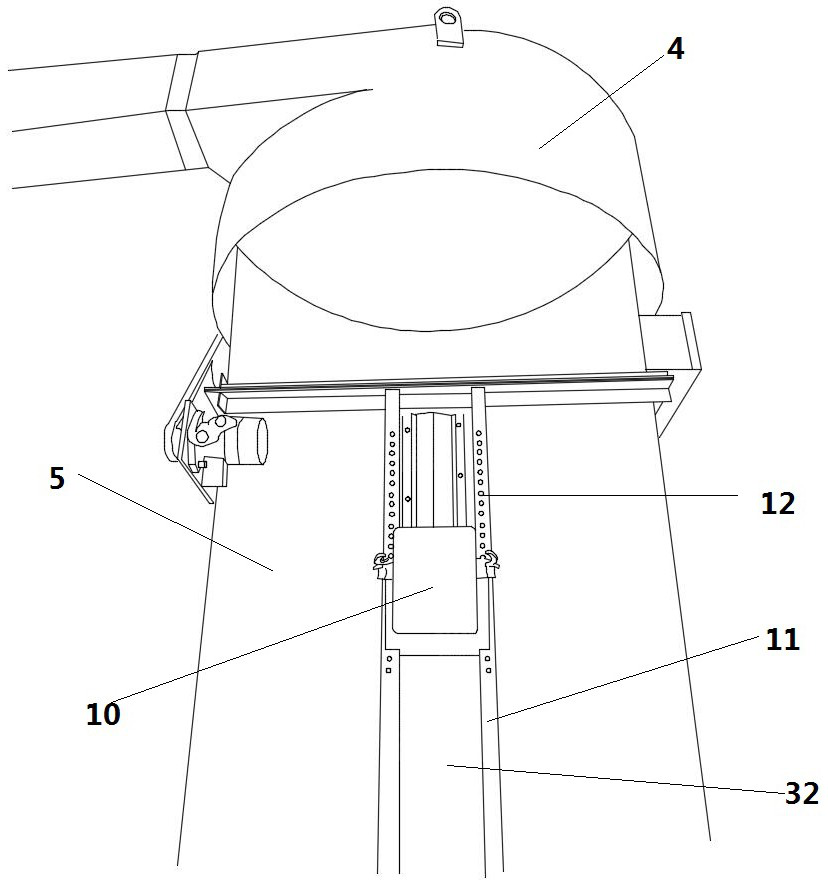

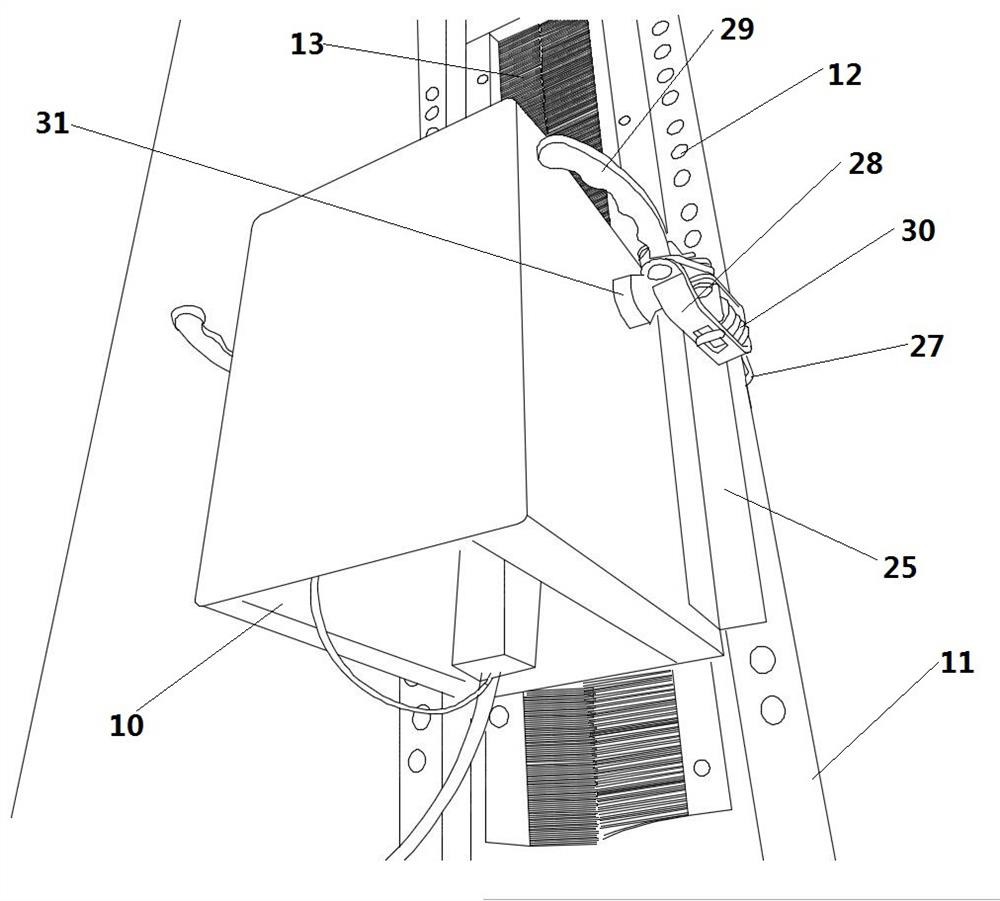

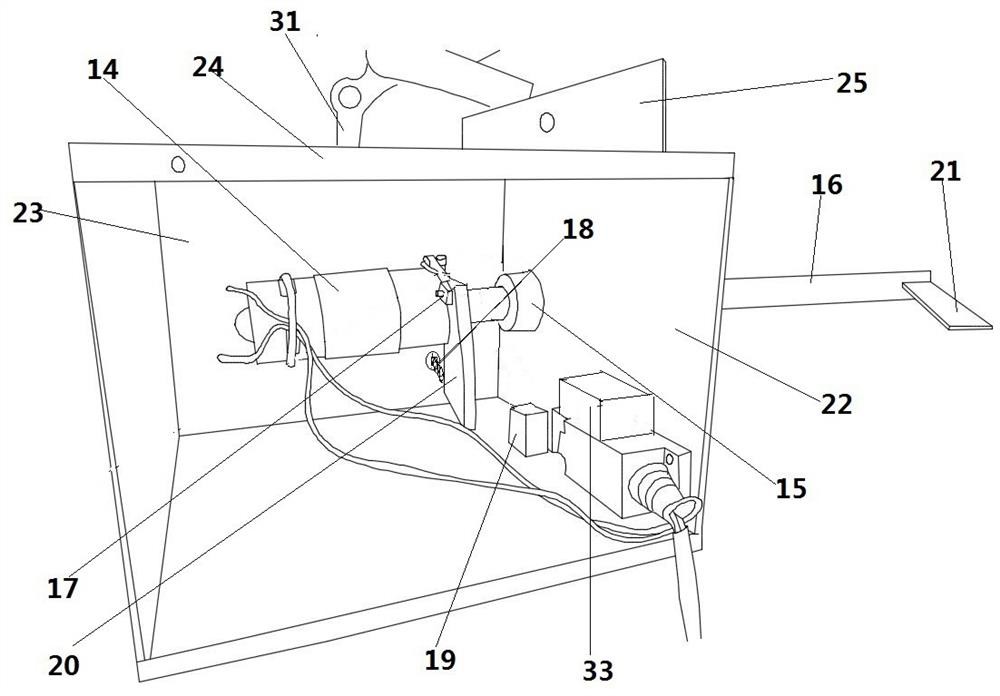

[0027] A material level detection device for a straw baler, comprising a box body 10, a motor, a detection rod 16, a proximity switch 19 and a positioning piece 20; the front panel 22 of the box body 10 is provided with a mounting bearing 15, and the motor is located inside the box body , the output shaft of the motor is connected to the detection rod 16 outside the box body 10 through the installation bearing 15, the detection rod 16 is provided with a detection blade 21, and the motor is suspended in the box body 10 by its output shaft and is close to the side panel of the box body 10 23; The positioning piece 20 is fixedly arranged on the motor housing 14, and the length of the positioning piece 20 is greater than the distance between the outer edge of the motor housing 14 and the side panel 23 of the box body 10; the box body 10 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com