Preparation method of porous graphene

A technology of porous graphene and graphene, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of difficult and precise control of conditions and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

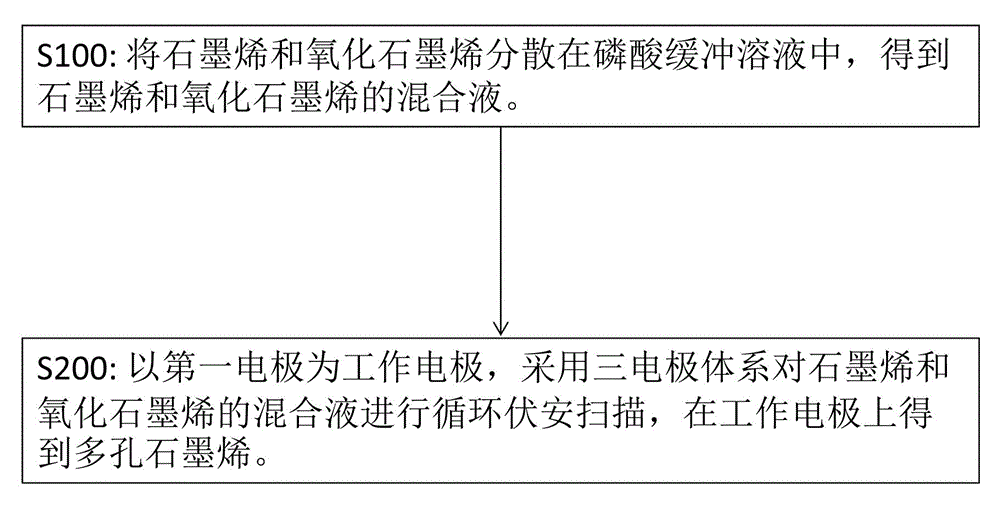

[0023] refer to figure 1 , a kind of preparation method of porous graphene of the present invention comprises:

[0024] Step S100: dispersing graphene oxide and graphene in a phosphate buffer solution to obtain a mixed solution of graphene and graphene oxide.

[0025] In one of the embodiments, step S100 is specifically: dispersing graphene and graphene oxide in phosphate buffer solution, the concentration of graphene in phosphate buffer solution is 1mg / mL, graphene oxide and graphene in phosphate buffer solution The concentration ratio in the mixture is 1:50-5:1 to obtain a mixed solution of graphene and graphene oxide.

[0026] In one embodiment, the pH value of the phosphate buffer solution is 4-6.

[0027] In one embodiment, the graphene oxide is prepared by the Hummers method, which is a classic method for preparing graphene oxide, and the quality of the prepared graphene oxide is reliable. Graphene is obtained by reducing graphene oxide prepared by the Hummers method ...

Embodiment 1

[0039] Graphene and graphene oxide are dispersed in a phosphate buffer solution with a pH value of 4, the concentration of graphene in a 0.1mol / L phosphate buffer solution is 1 mg / mL, and the concentration of graphene oxide in a phosphate buffer solution is 1 mg / mL. mL, to obtain a mixture of graphene and graphene oxide.

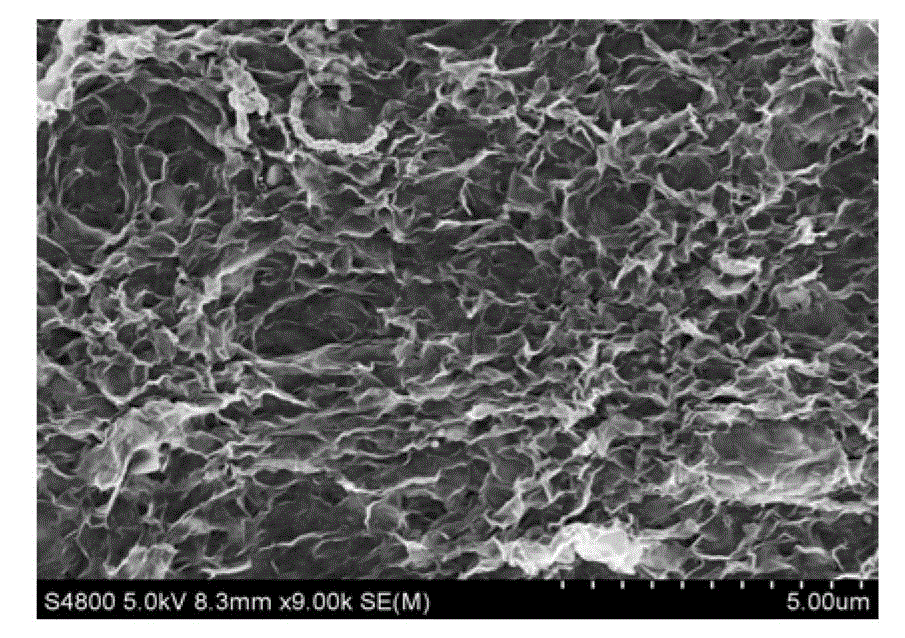

[0040] The glassy carbon electrode is used as the working electrode, the mixture of graphene and graphene oxide is dispersed and dropped on the glassy carbon electrode, and dried, then the modified glassy carbon electrode is used as the working electrode, the counter electrode is a platinum sheet electrode, and the reference electrode is a A saturated calomel electrode was placed in a 0.1mol / L blank phosphate buffer solution with a pH value of 4 for cyclic voltammetry scanning with a scanning potential of 0 V to -2.0 V and a scanning speed of 50 mV / s to obtain porous graphene-modified Working electrode, that is, porous graphene is obtained on the working ele...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that the concentration of graphene is 0.1 mg / mL, the pH value of the phosphate buffer solution is 5, the graphite electrode is used as the working electrode, the counter electrode is a platinum sheet electrode, and the reference electrode is saturated The calomel electrode was placed in a 0.1mol / L blank phosphate buffer solution with a pH value of 5 for cyclic voltammetry scanning, the scanning potential was from 0 V to -2.0 V, and the scanning speed was 50 mV / s, and the work of porous graphene modification was obtained. Electrode, that is, porous graphene is obtained on the working electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com