A silk soaking trolley

A trolley and silk technology, which is applied in the field of soaking device and silk soaking trolley, can solve the problems of inconvenient recovery of used silk soaking liquid, affecting the health of production and processing personnel, and inability to completely discharge parallel discharges, so as to maintain the Concentration, compact structure, the effect of improving soaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing of description, the present invention will be further described.

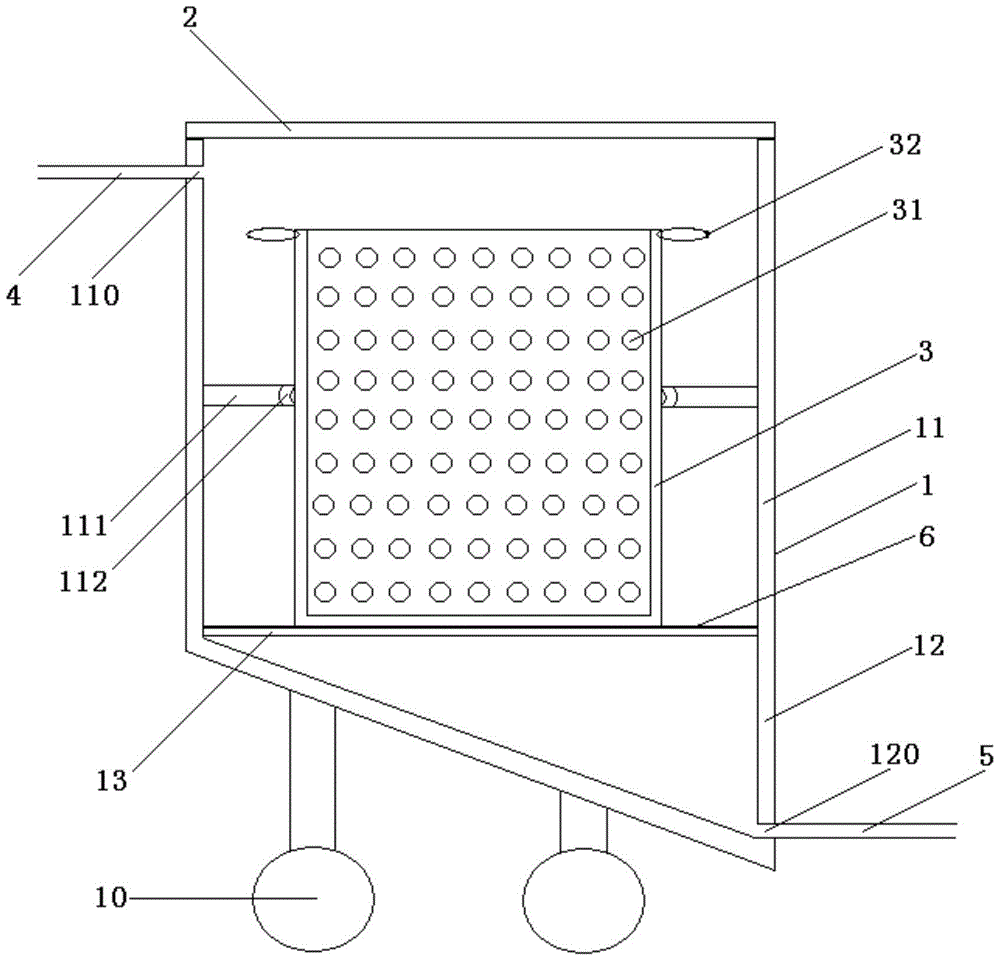

[0020] like figure 1 The shown silk soaking trolley includes a soaking bucket 1 with an open top surface, a cover 2 that can be opened and closed on the top of the soaking bucket 1, an inner bucket 3 set in the soaking bucket 1, and a The moving roller 10 on the bottom surface of the soaking tank 1 ;

[0021] Wherein, the soaking barrel 1 includes an upper barrel 11 for the set inner barrel 3, and a lower barrel 12 connected with the bottom surface of the upper barrel 11; Cylinder; the top surface of the lower barrel 12 is an open flat top surface, which matches the size of the bottom surface of the upper barrel 11, and the bottom surface of the lower barrel 12 is an inclined plane; the top of the side wall of the upper barrel 11 is provided with a liquid inlet The hole 110, the liquid inlet hole 110 is connected with the input pipe 4 for external supply o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com