Paving method of durable tunnel pavement

A durable, tunnel technology, applied in the field of transportation engineering, can solve the problems of hidden safety hazards and construction, poor skid resistance, poor workability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

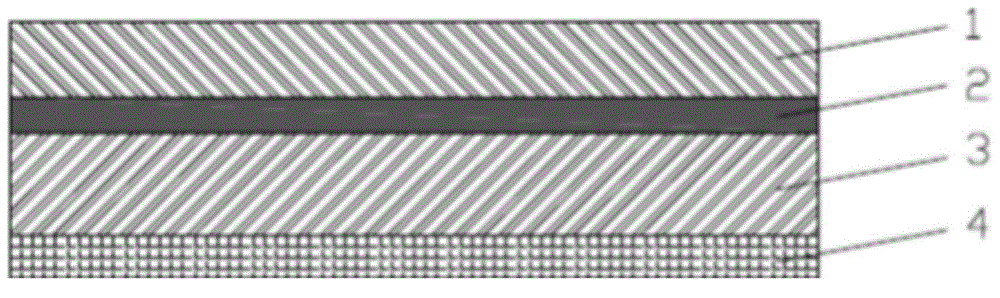

[0064] The pavement method of the durable tunnel pavement of the present embodiment comprises the following steps:

[0065] (1) Sandblast the cement concrete slab to remove the surface laitance; use a synchronous crushed stone sealer to spread rubber asphalt and gravel, the amount of rubber asphalt per square meter is 2.2kg, and the amount of gravel per square meter is 12.0kg, The particle size of the crushed stone is 9.5mm-13.2mm. It is compacted with a 25-ton rubber-tyred road roller and rolled three times. The thickness of the rubber asphalt crushed stone seal layer is 1.0cm;

[0066](2) To pave the lower layer, first pave 4cm of OGFC-13 with a void rate of 20%, after natural cooling, pour cement-based mortar, use a small vibratory roller to assist grouting, and use a sweeper to remove the surface cement laitance after initial setting , natural maintenance for 3-5 days, forming a 4cm perfusion semi-flexible mixture pavement lower layer;

[0067] (3) according to 0.5kg / m 2...

Embodiment 2

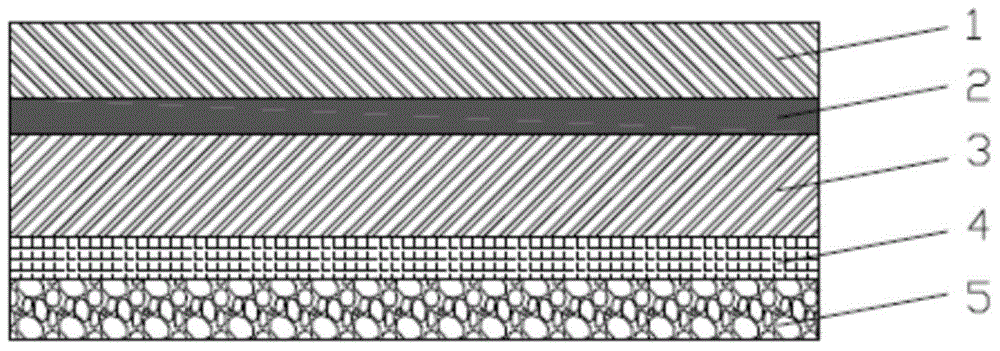

[0072] The pavement method of this implementation durable type tunnel pavement comprises the following steps:

[0073] (1) Sandblast the cement concrete slab to remove the surface laitance; use a synchronous gravel sealer to spread rubber asphalt and gravel, the amount of rubber asphalt per square meter is 2.0kg, and the amount of gravel per square meter is 10.0kg, The particle size of the crushed stone is 9.5mm-13.2mm. It is compacted with a 25-ton rubber-tyred road roller and rolled three times. The thickness of the rubber asphalt crushed stone seal layer is 1.5cm;

[0074] (2) To pave the lower layer, first pave 5cm of OGFC-16 with a void ratio of 22%. After natural cooling, pour cement-based mortar, use a small vibratory roller to assist grouting, and use a sweeper to remove the surface cement laitance after initial setting , natural maintenance for 3-5 days, forming a 5cm perfusion semi-flexible mixture pavement lower layer;

[0075] (3) According to 0.4kg / m 2 Sprinkle ...

Embodiment 3

[0080] The pavement method of the durable tunnel pavement of the present embodiment comprises the following steps:

[0081] (1) Sandblast the cement concrete slab to remove the surface laitance; use a synchronous crushed stone sealer to spread rubber asphalt and gravel, the amount of rubber asphalt per square meter is 2.2kg, and the amount of gravel per square meter is 12.0kg, The particle size of the crushed stone is 9.5mm-13.2mm, and it is compacted with a 25-ton rubber-tyred road roller, rolling twice, and the thickness of the rubber asphalt crushed stone seal layer is 1.5cm;

[0082] (2) To pave the lower layer, first pave 6cm of OGFC-20 with a void rate of 25%, after natural cooling, pour cement-based mortar, use a small vibratory roller to assist grouting, and use a sweeper to remove the surface cement laitance after initial setting , keep in good health for 3-5 days, and form a 6cm perfusion semi-flexible mixture pavement lower layer;

[0083] (3) according to 0.5kg / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com