A High Efficiency Horizontal Condensing Gas Industrial Boiler

A high-efficiency technology for industrial boilers, which is applied in the field of gas-fired boilers, can solve problems such as the inability to absorb high-level latent heat energy of flue gas, and achieve the effects of reducing exhaust gas temperature, increasing furnace temperature, and enhancing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

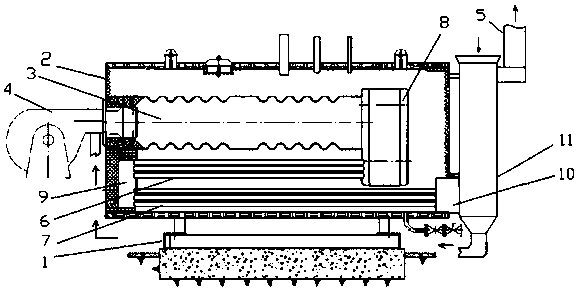

[0023]The present invention includes a boiler base 1, a drum 2, a furnace 3, a burner 4, a chimney 5, a second return condenser 6, a third return condenser 7, a high-temperature backfire chamber 8, a front smoke chamber 9, and a rear smoke chamber 10. Heat exchanger 11 in the rear smoke chamber. In the above structure, the boiler base 1, the drum 2, the furnace 3, the burner 4, the chimney 5, the second return condenser 6, the third return condenser 7, the high temperature combustion chamber 8, the front smoke chamber 9, the rear The smoke chamber 10 is a part of the existing common gas-fired industrial boilers, but a revolutionary change has been made in the installation position, which makes the present invention completely different from the existing common gas-fired industrial boilers, and has achieved unprecedented high thermal efficiency and exhaust gas temperature. Level.

[0024] Shown in the figure, the present invention is significantly different in structure compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com