Ferromagnetic pipeline quantitative lossless evaluating method based on nonlinear magnetic saturation pulsed eddy current

A pulsed eddy current and evaluation method technology, which is applied in the fields of material magnetic variables, measuring devices, and material analysis through electromagnetic means, can solve problems such as reducing the skin depth of eddy currents, reducing material permeability, and failing to detect thick plate defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

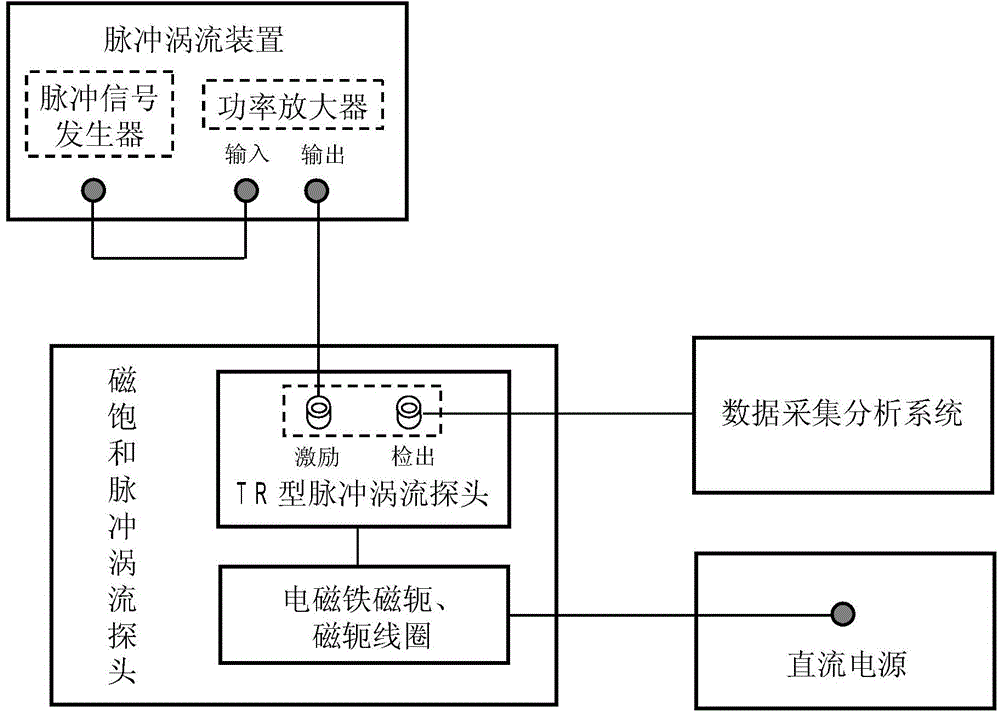

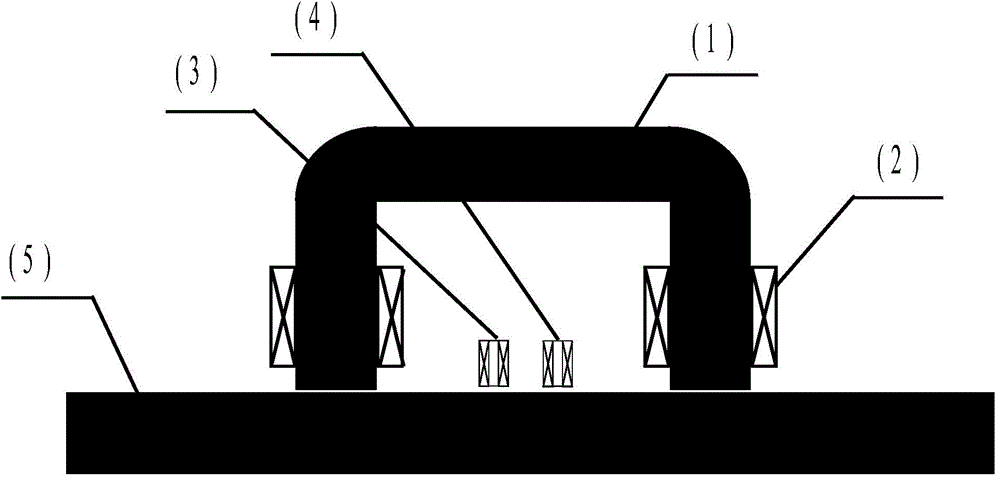

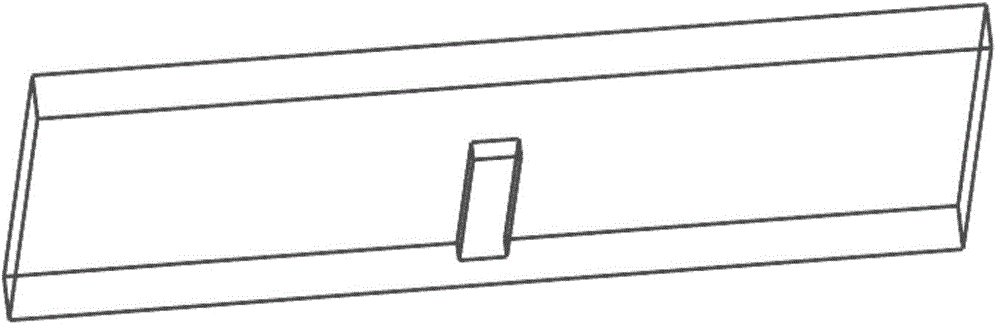

[0051] like figure 1 , figure 2 and image 3 As shown, the detection steps of the method of the present invention are: passing a strong direct current into the yoke coil 2 to form a strong static magnetic field, so that the detected ferromagnetic material 5 is in a state of magnetic saturation, reducing its magnetic permeability and enhancing the skin of eddy currents depth. When the ferromagnetic material 5 to be tested is in a state of magnetic saturation, the excitation probe of the TR-type pulsed eddy current probe, that is, the excitation coil 3, is excited by a pulse signal through the pulsed eddy current device. Transient eddy current, the existence of defects will affect the distribution of the eddy current, thus affecting the distribution of the transient secondary magnetic field generated by the eddy current. The voltage across the detection probe, that is, the detection coil 4, will change accordingly, which is collected by the data acquisition and analysis syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com