Solid propellant flameout critical pressure reduction rate testing method

A technology of solid propellant and depressurization rate, which is applied in the direction of chemical analysis by means of combustion, can solve the problems of difficult control of initial pressure, uncertain pressure of test samples, initial pressure fluctuations, etc., and achieve the effect of expanding the test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

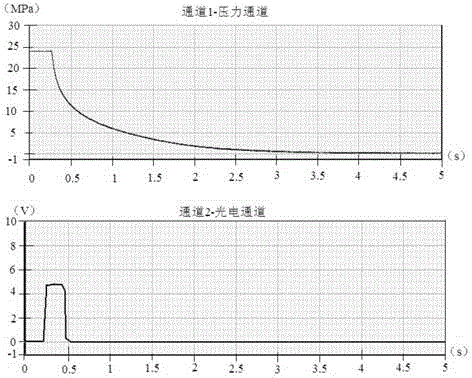

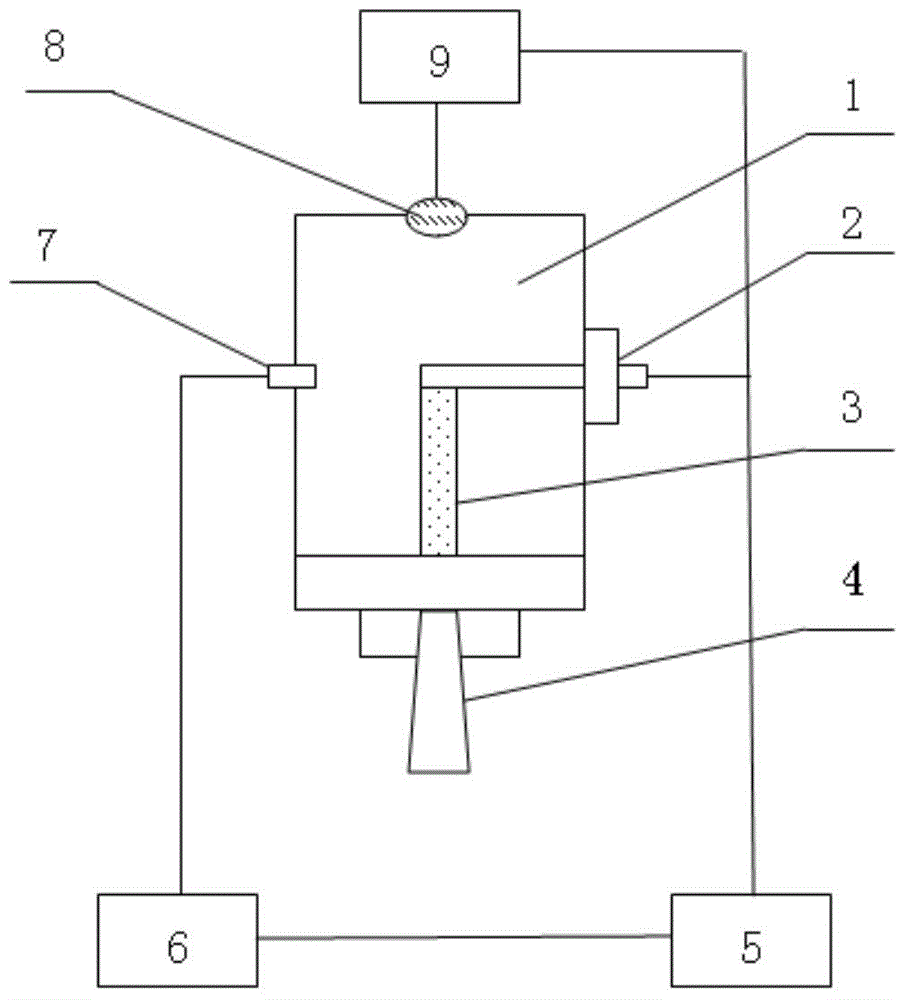

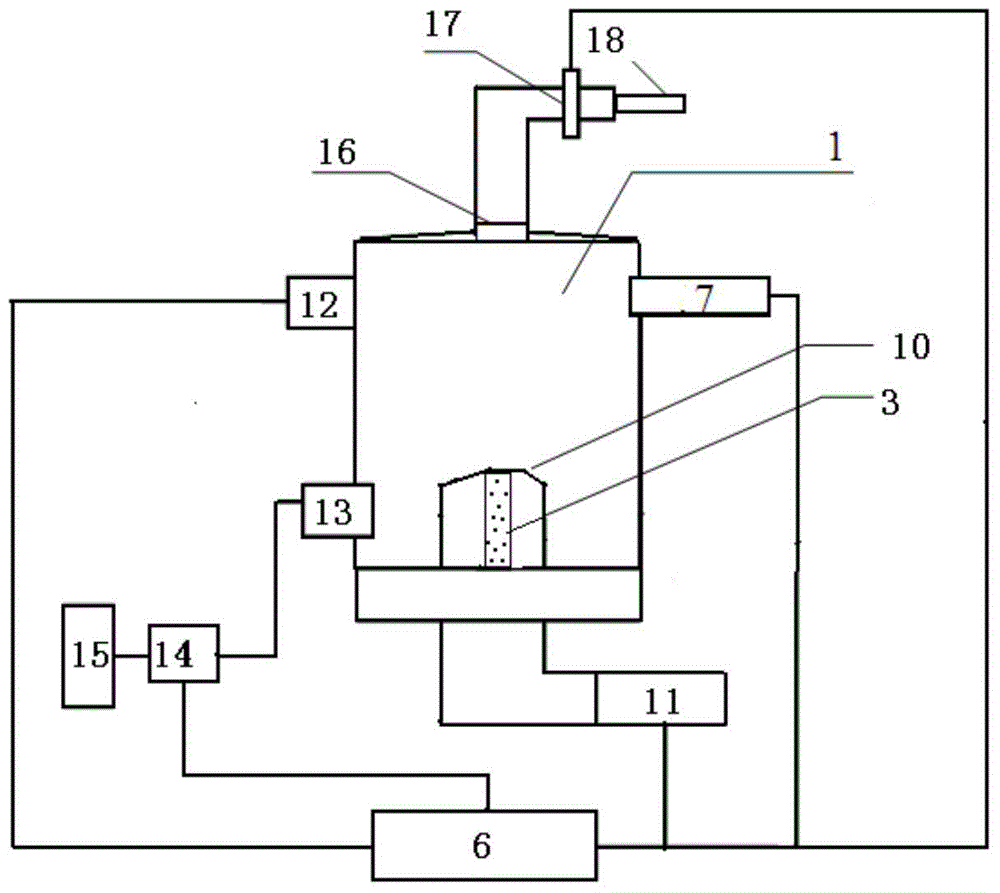

[0032] refer to figure 1 , 2, the main device that the present invention adopts is combustion chamber 1, is made of stainless steel, and volume is about 80ml ± 10ml, should be qualified through resistant 45MPa hydrostatic test. There are holes for testing pressure and testing light intensity on the side wall of combustion chamber 1, and pressure sensor 7 and photoelectric sensor 12 are installed respectively. The pressure sensor 7 adopts a pressure transmitter with a model of CYG41000 and a range of 0-30 MPa; the photoelectric sensor 12 adopts a photomultiplier tube in the infrared band, with a DC output of 0-10V. The lower part of the combustion chamber 1 is provided with an air inlet 13, and the air inlet 13 is connected with a booster pump 14 and a high-pressure gas cylinder 15 with a stainless steel pipe. , cylinder pressure: 13.5±0.5MPa, purity: N 2 ≥99.5%. The top of the combustion chamber 1 is a gas outlet, and a filter screen 16 is installed at the outlet, and is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com