A sensorless predictive torque control system and method for an asynchronous motor

A technology for asynchronous motors and torque prediction, applied in control systems, vector control systems, motor generator control, etc., can solve problems such as insufficient control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

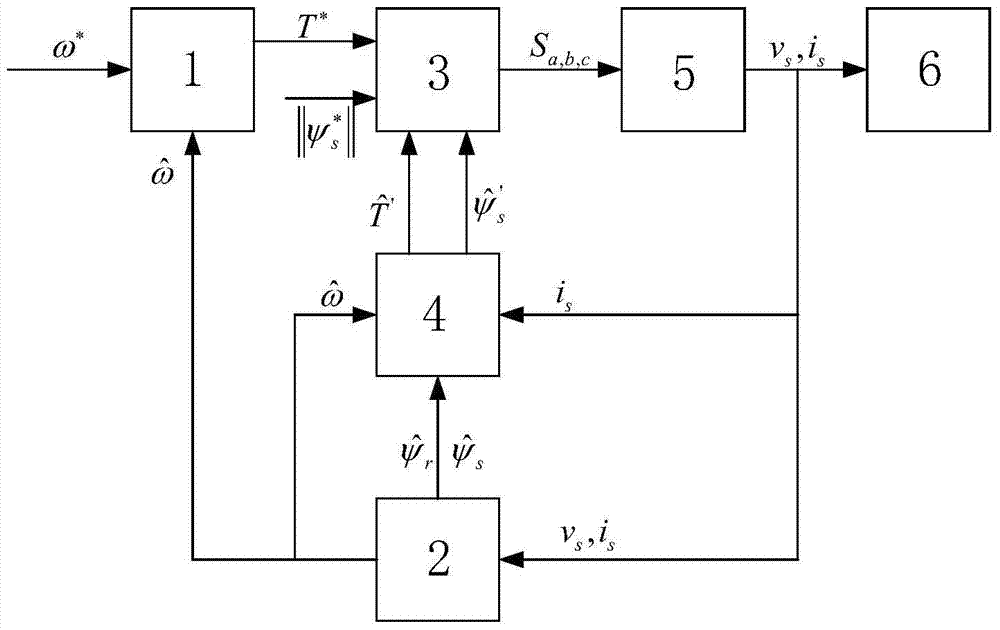

[0098] like Figure 1-2 As shown, a sensorless predictive torque control system for an asynchronous motor according to the present invention includes a first PI controller 1, a model reference adaptive observer 2, and an optimization module 3; the first PI controller 1, and an optimization module 3 The model reference adaptive observer 2 is connected to each other in pairs; the asynchronous motor sensorless predictive torque control system is connected to the inverter 5 when used, and the inverter 5 is connected to the asynchronous motor 6;

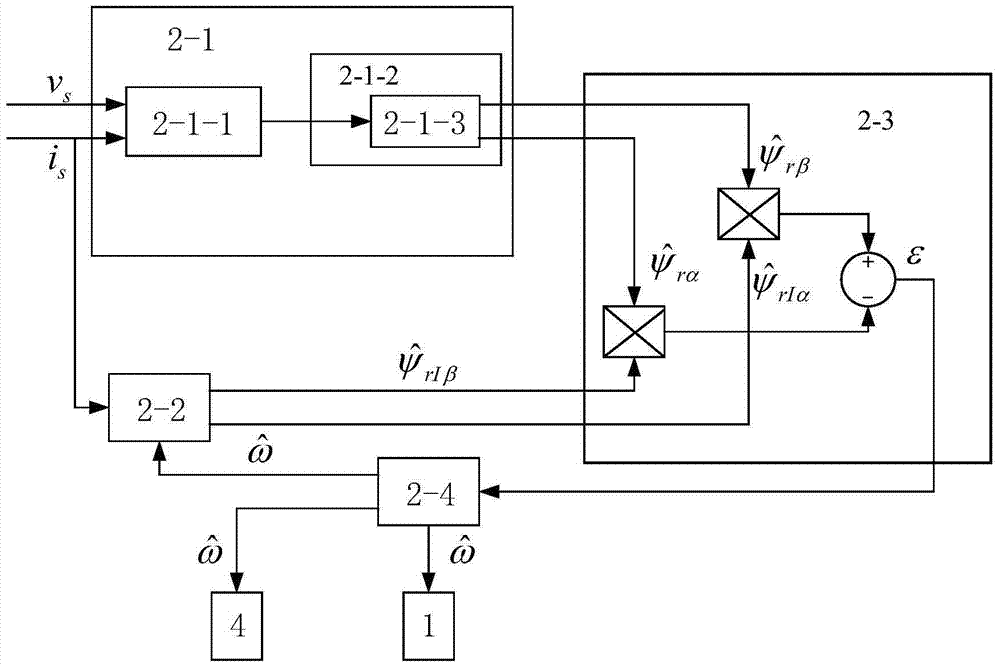

[0099] The model refers to an adaptive observer 2 for the stator voltage v obtained at the output of the inverter 5 s and stator current i s Calculate the observed speed by formula 1-4 The model reference adaptive observer 2 includes a reference module 2-1, an adjustable module 2-2, a rotor flux deviation calculation module 2-3 and a second PI controller 2-4, a reference module 2-1, an adjustable module 2-2 are respectively connected ...

Embodiment 2

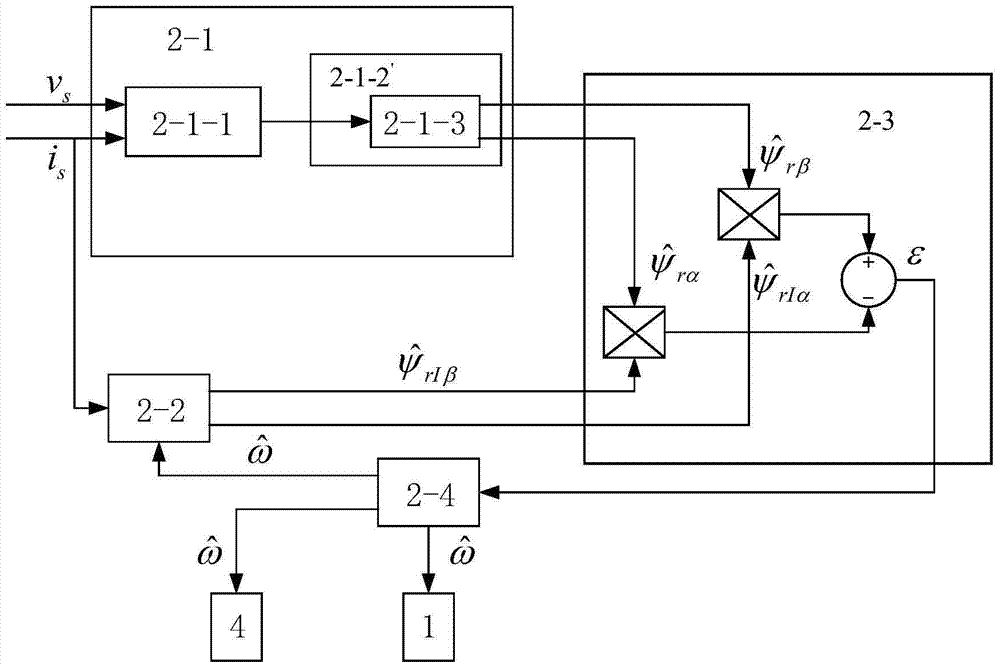

[0133] like figure 1 , 3 As shown, it differs from Embodiment 1 in that:

[0134] The sliding mode compensation module 2-1-2 is replaced by the sliding mode compensation optimization module 2-1-2', and the third PI controller 2-1-3 in the sliding mode compensation optimization module 2-1-2' utilizes Self-adjustable proportional gain of K kp and integral gain K ki The sliding mode gain K is calculated by formula 5, and the sliding mode gain K is used for sliding mode compensation, and formula 1 is corrected to formula 1", the above formula is as follows,

[0135]

[0136]

[0137]

[0138] Among them, Sat(S) is a continuous function with saturation characteristics, x=i sα and i sβ , Δ is a non-negative adjustment parameter.

[0139] In order to further verify the effectiveness of the observer proposed in this implementation example and the overall performance of the sensorless control system based on the observer, this embodiment is applied to an asynchronous m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com