System and method for treating waste gas containing VOCs (volatile organic compounds)

A technology of a treatment system and a treatment method, applied in the field of waste gas treatment, can solve the problems of large atmospheric emissions, incomplete VOCs adsorption, and reduced desorption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

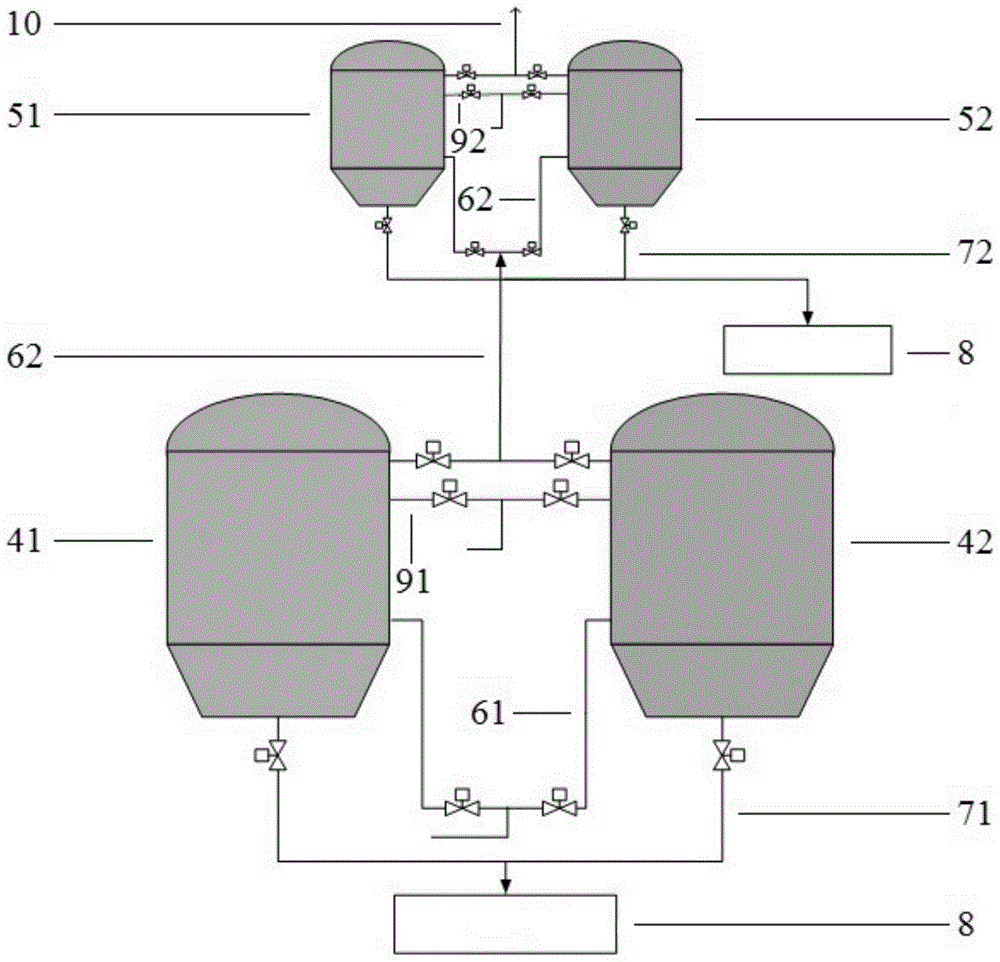

[0068] Adopt the treatment system and the treatment method of VOCs waste gas provided by the present invention to process the battery production enterprise waste gas, specifically as follows:

[0069] Adsorption: VOCs-containing exhaust gas (VOCs concentration greater than 6500ppm) enters the first-stage adsorption tank through the first-stage exhaust gas delivery pipeline, removes VOCs in the exhaust gas through activated carbon adsorption, and then enters the second-level adsorption tank through the second-level exhaust gas delivery pipeline, and is again adsorbed and desorbed by activated carbon After removing the VOCs in the exhaust gas, it is discharged to the atmosphere through the clean gas discharge pipe, and the emission concentration of VOCs is less than 45.5ppm;

[0070] Desorption: High-pressure water vapor enters the first-level desorption tank and the second-level desorption tank through the first-level steam delivery pipeline and the second-level steam delivery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com