A water heater liner welding positioning device

A water heater liner and welding positioning technology, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inaccurate positioning and low efficiency, and achieve the goals of reducing weld seams, improving product quality, and avoiding false welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

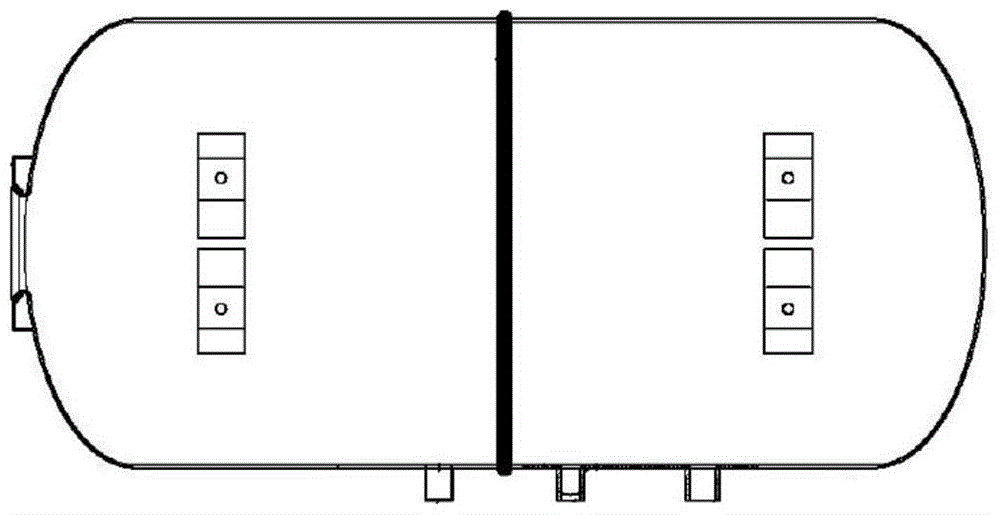

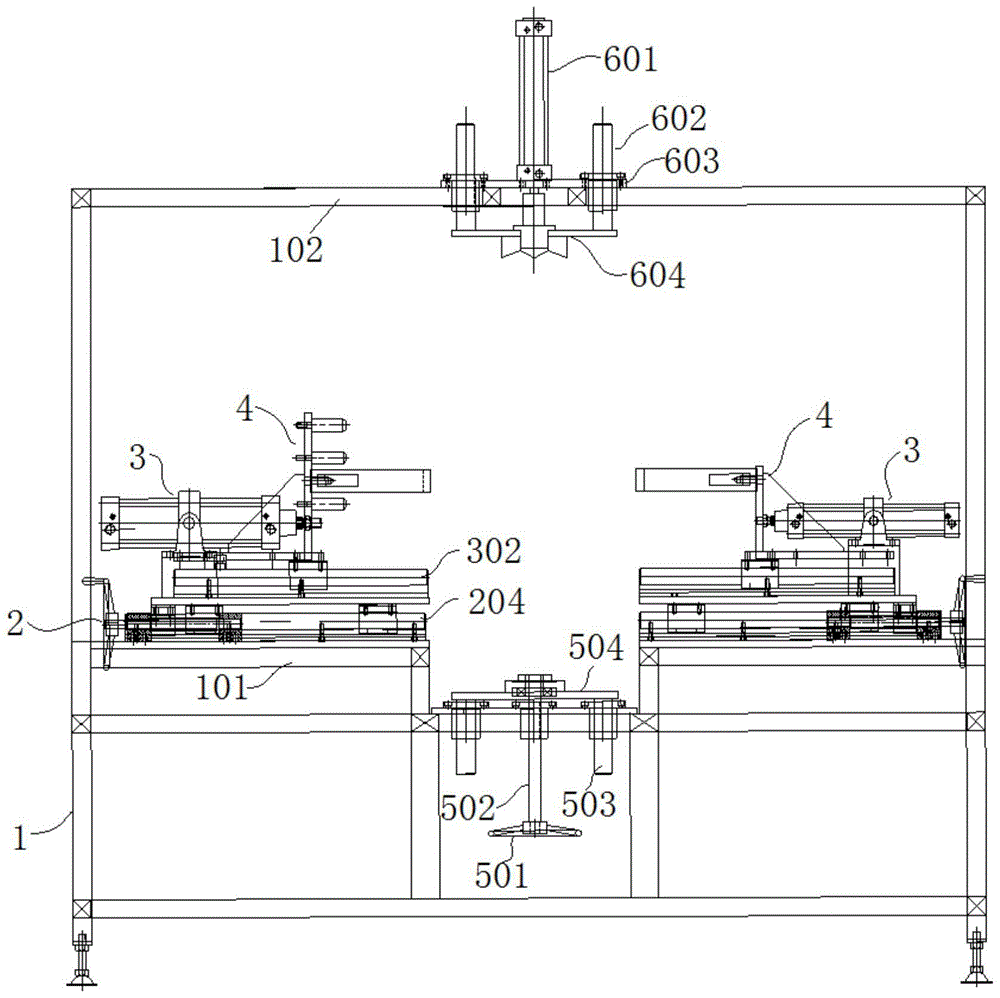

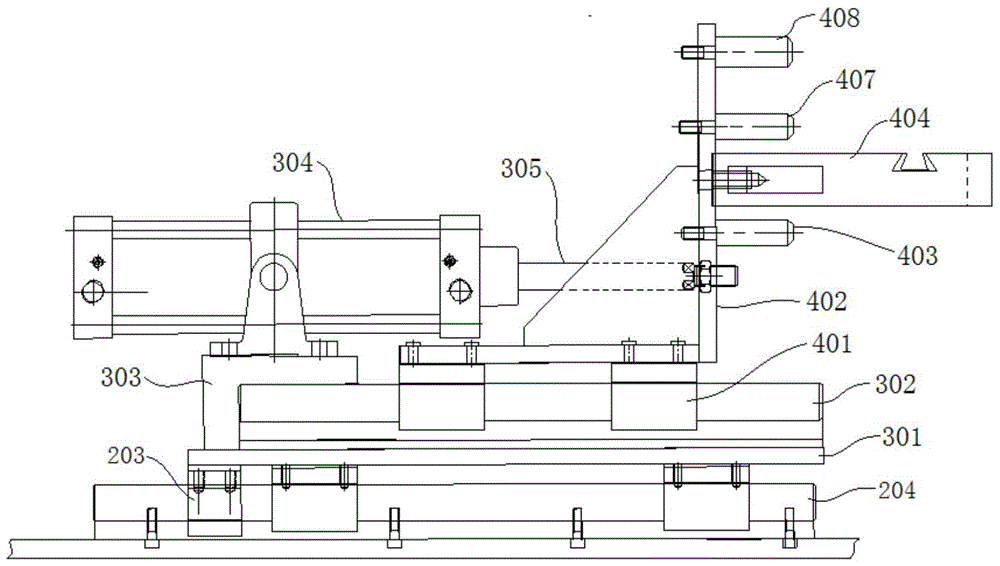

[0032] to combine figure 2 , A water heater liner welding positioning device of this embodiment is mainly composed of a bracket 1, clamping devices installed on both sides of the bracket 1 and a support table between the two clamping devices. A workbench 101 is arranged on both sides of the support 1 , and the clamping device is arranged on the workbench 101 . The clamping device includes a linear slide rail assembly 2 , a pressing assembly 3 and a centering assembly 4 . Wherein, the linear slide rail assembly 2 is arranged on the bracket 1, and a slide rail connecting plate 301 is provided in the pressing assembly 3, and the slide rail connecting plate 301 is slidably connected with the first slide rail 204 in the linear slide rail assembly 2; The centering assembly 4 is slidably connected to the pressing assembly 3 , and the pressing assembly 3 controls the centering assemblies 4 on both sides of the support table to engage with each other.

[0033] to combine figure 2 ...

Embodiment 2

[0041] combine figure 2 , a water heater liner welding positioning device of this embodiment, its structure is the same as that of Embodiment 1, the difference is that a top beam 102 is arranged on the top of the bracket 1 in this embodiment, and a top beam 102 is set on the top beam 102 There is a top hold-down device. The top pressing device includes a longitudinal pressing hydraulic cylinder 601, a top slide bar 602, a top fixing plate 603 and a top pressing sleeve 604. The longitudinal pressing hydraulic cylinder 601 is fixedly connected with the top beam 102 through the top fixing plate 603, and the longitudinal pressing hydraulic pressure The piston rod of the cylinder 601 drives the top pressing sleeve 604 to move up and down. Two top sliding rods 602 are arranged symmetrically with respect to the longitudinal compression hydraulic cylinder 601, and the top sliding rods 602 are slidingly connected with the top fixing plate 603, and the lower ends of the top sliding ro...

Embodiment 3

[0044] A water heater liner welding positioning device of this embodiment has the same structure as that of Embodiment 2, the difference is that in this embodiment, each centering collar 404 is provided with two spot welding ports 405 at intervals .

[0045] According to Embodiments 1 to 3, for the welding positioning device of the present invention, in specific use, the process is as follows:

[0046] Step 1. According to the height of the upper cylinder of the water heater liner, then turn the bottom handwheel 501 to adjust the height of the bottom support plate 504 to correspond to the height of the upper cylinder of the water heater liner; turn the side handwheel 201 to adjust the centering assembly 4 horizontal intervals to suit the size of the inner tank of the water heater;

[0047] Step 2. Buckle the upper body of the water heater liner upside down on the bottom support plate 504, the opening of the water heater liner is engaged with the circular sleeve, centered axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com