Painting paper added with blanching bamboo pulp meal and fiber grafting agent and preparation method of painting paper

A technology of grafting agent and bamboo pulp, which is applied in the field of calligraphy and painting paper and its preparation with bleached bamboo pulp and fiber grafting agent, can solve the problems of poor viscose filtration performance, bamboo Problems such as difficulties in selling pulp, etc., to achieve the effect of improving the use value, good ink absorption and ink retention, and long-term storage without discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A calligraphy and painting paper pulping process, comprising the following:

[0030] A, slurry composition and percentage by weight are: bleached bamboo pulp 20%, bleached bamboo pulp 80%;

[0031] B. The components and weight percentages of auxiliary materials are as follows: 1.5% talcum powder consumption, 1.0% fiber grafting agent consumption, and 0.5% oleander gum consumption.

[0032] C. Mix the above slurry evenly in the slurry mixing tank, and the mixing time is 0.5h;

[0033] D. Transporting the slurry treated in step C to a paper machine for papermaking to obtain painting and calligraphy paper.

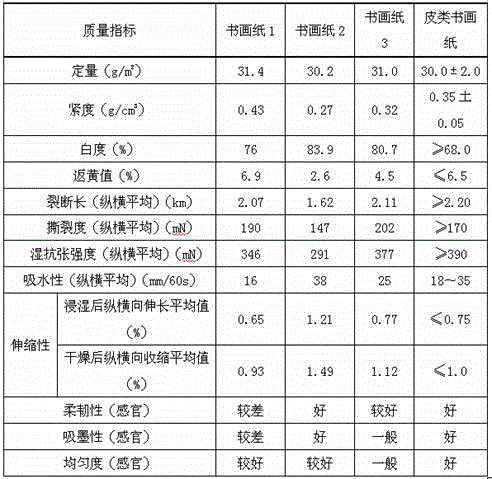

[0034] The quality of the calligraphy and painting paper prepared in Example 1 was compared with the quality of bleached bamboo pulp calligraphy and painting paper (the product was obtained from a calligraphy and painting paper factory in Jiajiang) and the national standard for leather calligraphy and painting paper. The results are shown in Table 1.

[0035]Table 1 ...

Embodiment 2

[0041] A calligraphy and painting paper pulping process, comprising the following:

[0042] A, slurry composition and percentage by weight are: bleached bamboo pulp 40%, bleached bamboo pulp 60%;

[0043] B. The components and weight percentages of auxiliary materials are as follows: 1.0% talcum powder consumption, 0.75% fiber grafting agent consumption, and 0.3% oleander gum consumption.

[0044] C. Mix the above slurry evenly in the slurry mixing tank, and the mixing time is 1.5h;

[0045] D. Transporting the slurry treated in step C to a paper machine for papermaking to obtain painting and calligraphy paper.

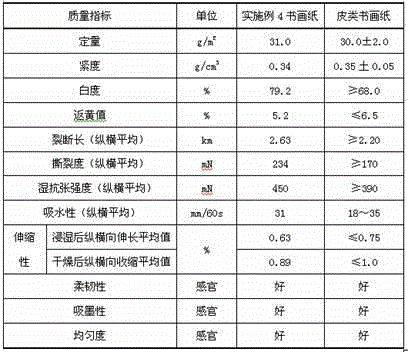

[0046] The quality of the calligraphy and painting paper prepared in Example 2 is compared with the national standard for leather calligraphy and painting paper, and the results are shown in Table 2.

[0047] Table 2 Comparison of the quality of calligraphy and painting paper and leather calligraphy and painting paper in Example 2

[0048]

[0049] By comparison...

Embodiment 3

[0051] A calligraphy and painting paper pulping process, comprising the following:

[0052] A, slurry composition and percentage by weight are: bleached bamboo pulp 60%, bleached bamboo pulp 40%;

[0053] B. The components and weight percentages of auxiliary materials are: 0.75% talcum powder consumption, 0.5% fiber grafting agent consumption, and 0.1% oleander gum consumption.

[0054] C. Mix the above slurry evenly in the slurry mixing tank, and the mixing time is 1.0h;

[0055] D. Transporting the slurry treated in step C to a paper machine for papermaking to obtain painting and calligraphy paper.

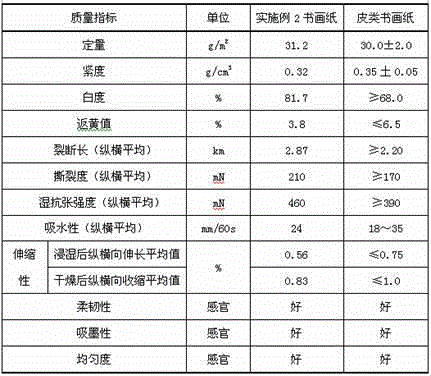

[0056] The quality of the calligraphy and painting paper prepared in Example 3 is compared with the national standard for leather calligraphy and painting paper, and the results are shown in Table 3.

[0057] Table 3 Comparison of the quality of calligraphy and painting paper and leather calligraphy and painting paper in Example 3

[0058]

[0059] By contrast, it can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com