Backlight assembly

A technology of backlight components and backplanes, applied in the direction of optical components, optics, light guides, etc., can solve the problems of low cost, insufficient hardness, and easy damage of plastic structures, and achieve the effects of material saving, low cost, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

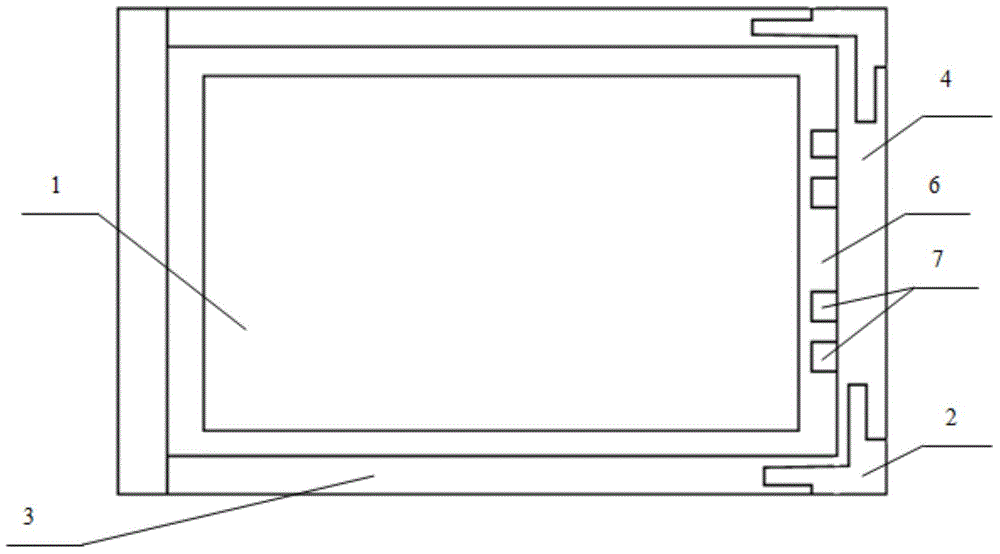

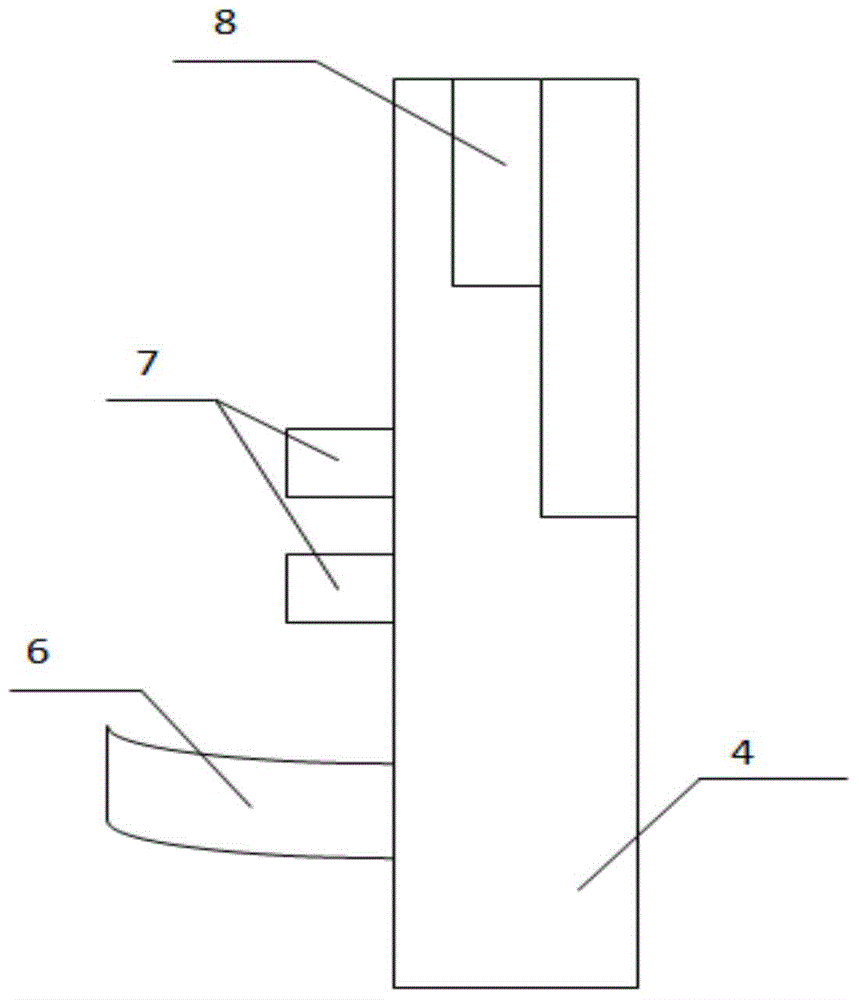

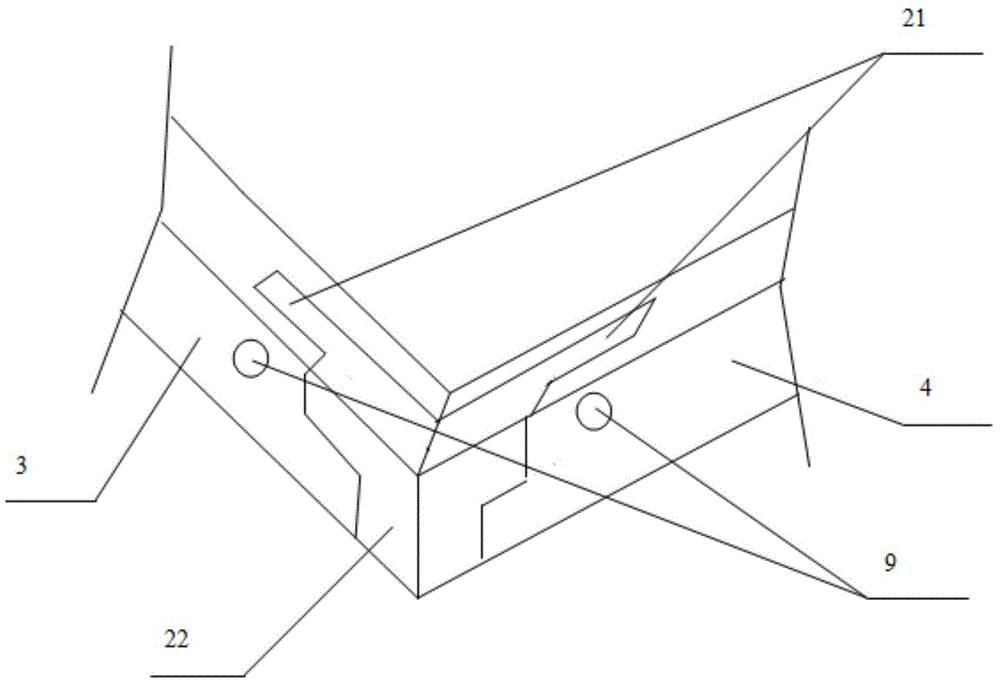

[0021] A backlight assembly, including a backplane 1, a frame, and a connector 2. From the backplane 1, a reflective sheet, a backlight light source, and an acrylic light guide plate are sequentially arranged from bottom to top. The backplane 1 is made of tempered glass, and the cross-section It is arc-shaped; the frame is made of aluminum alloy, including a horizontal frame 3 and a vertical frame 4, the horizontal frame 3 has a U-shaped groove matching the horizontal side of the back plate 1, and the vertical frame 4 has a The U-shaped groove 6 matching the vertical side of the backboard 1, the backboard 1 is installed in the four-sided U-shaped groove frame surrounded by two horizontal frames 3 and two vertical frames 4; the horizontal frame 3 and the vertical frame The frame 4 is connected through the connecting piece 2 .

[0022] The four sides of the backboard 1 are provided with cushion layers, which can increase the friction between the backboard 1 and the frame, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com