Heat pump type fruit and vegetable drying machine

A technology for dryers, fruits and vegetables, applied in dryers, drying, heat pumps, etc., can solve the problems of long processing time, low production efficiency, secondary pollution, etc., and achieve significant energy saving effect, small drying heat loss, The effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

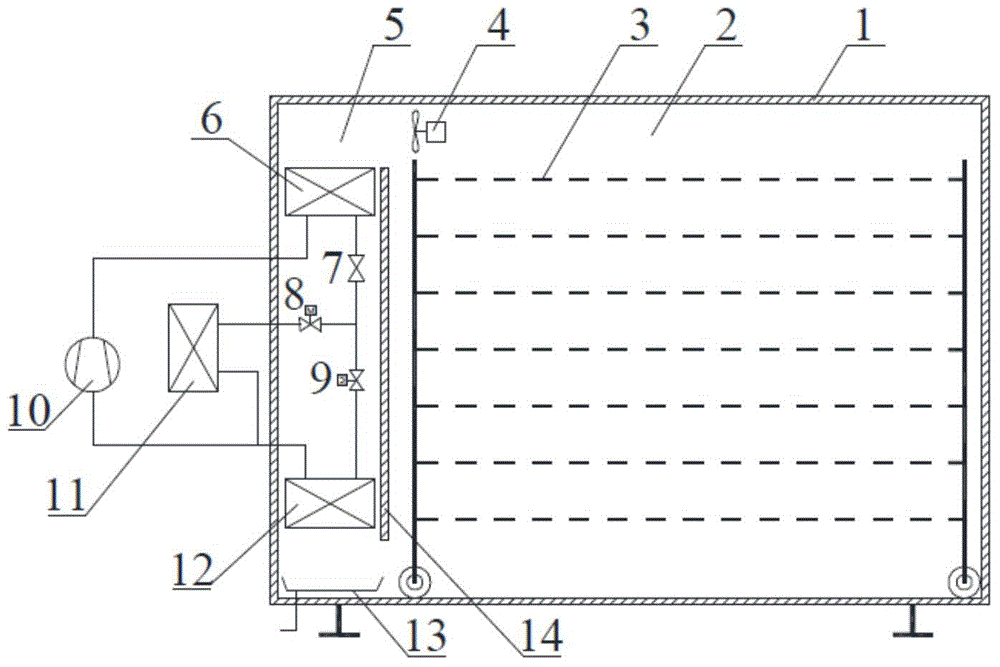

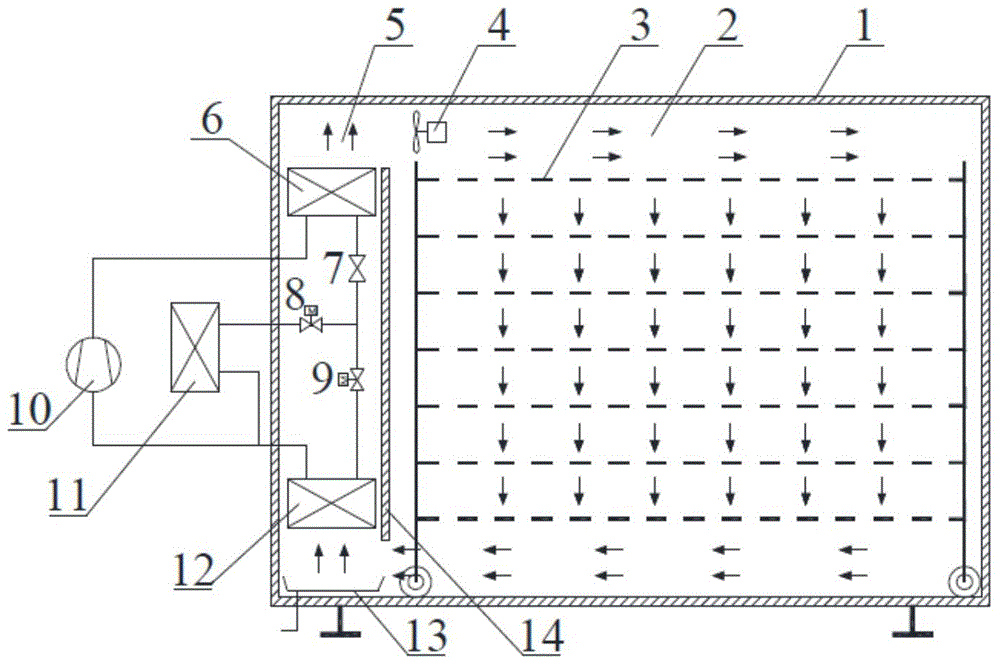

[0017] like figure 1 As shown, a heat pump type fruit and vegetable dryer consists of a drying box 1, an inner partition 14, a circulating fan 4, a fruit and vegetable tray rack 3, a compressor 10, a condenser 6, a first evaporator 11, and a second evaporator 12. The throttling valve 7, the first electromagnetic shut-off valve 8, the second electromagnetic shut-off valve 9, and the water tray 13 are composed. The drying box 1 is made of a 10cm thick polyurethane insulation board, and the side wall is provided with an inlet and outlet door; the inner partition 14 separates the drying box into two parts, an air treatment chamber and a drying chamber. A certain gap is reserved at the top of the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com