Slab lens for realizing plane wave focusing by adopting metastructure surface

A technology of flat lens and metasurface, applied in lens, optics, instrument, etc., can solve the problems of poor image quality, difficult lens processing, etc., and achieve the effect of great flexibility and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

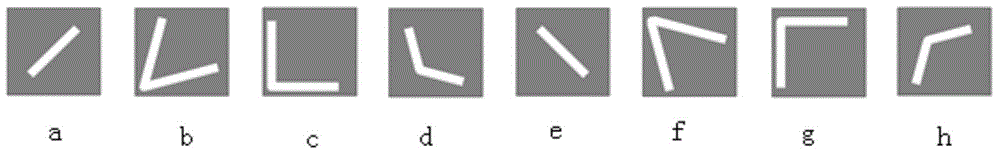

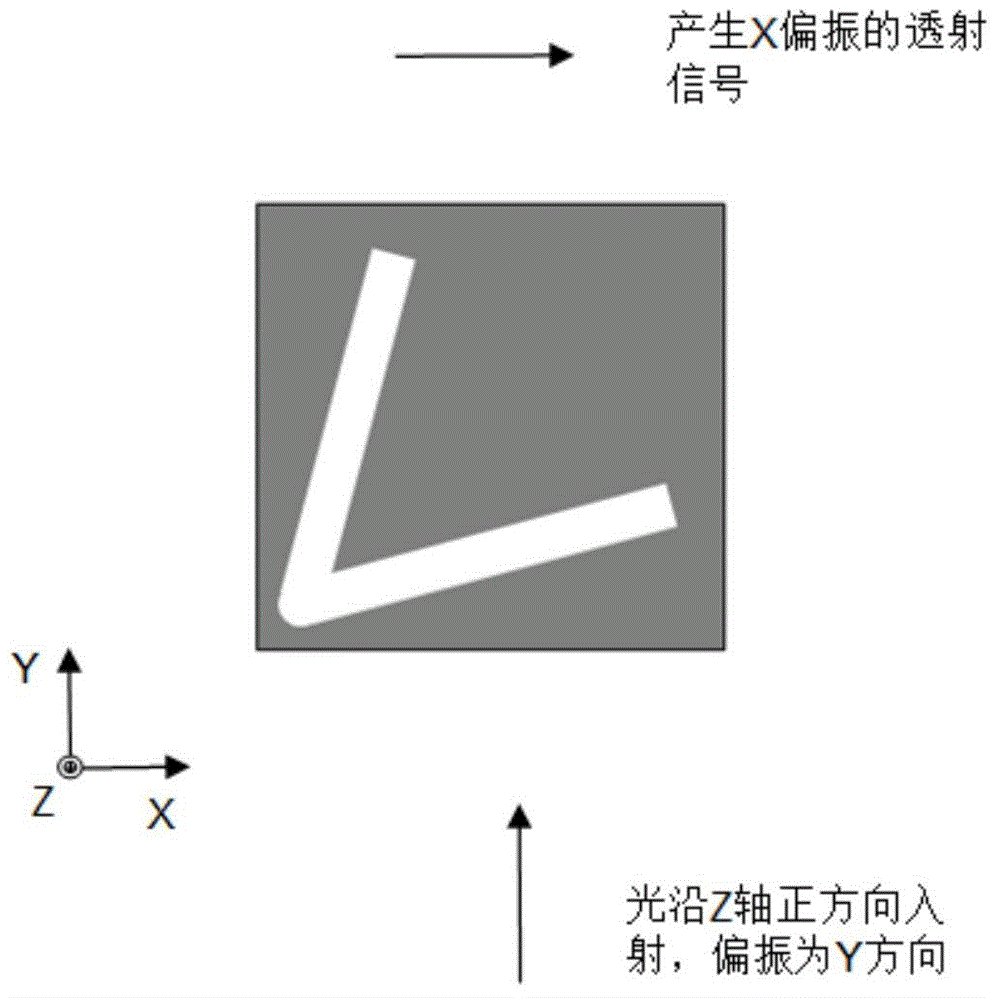

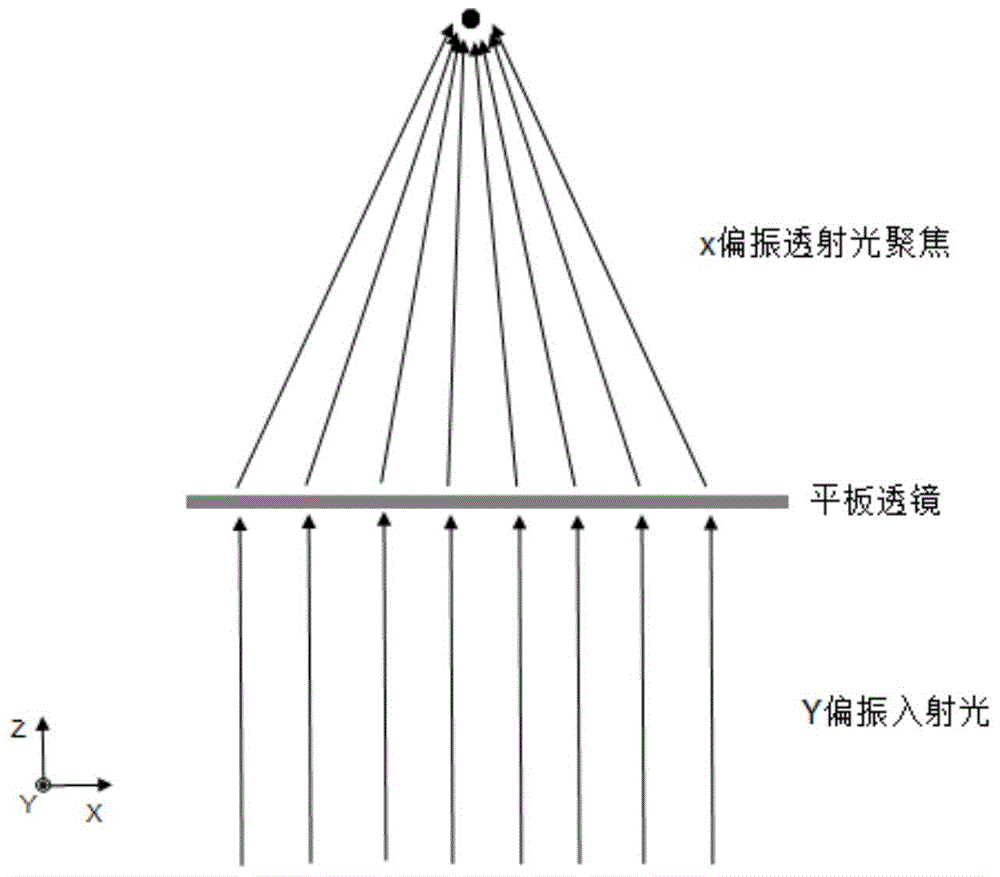

[0021] Firstly, the V-shaped structure parameters of different phases are obtained through theoretical simulation. For a flat lens, the higher the spatial resolution, the better, so it is necessary to adjust the area occupied by a single V-shaped structure as small as possible. By adjusting the opening angle and length and width of the V-shaped structure, the phase and conversion efficiency of vertically polarized light can be adjusted. Figure 4 It is a schematic diagram of the smallest unit of the V-shaped hole distribution of 8 different phases of the flat lens of the present invention.

[0022] In the present invention, for incident plane wave wavelength is 1550nm, design 8 kinds of V-shaped structural units to be square (see figure 1 ), the side length is 550nm, which is about one-third of the wavelength, so it has better spatial resolution. By adjusting the opening angle and length of the V-shaped structure, when a beam of Y-polarized plane waves is incident on its su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com