Mask plate, manufacturing method of mask plate and OLED device packaging method

An encapsulation method and mask technology, which are applied to electric solid-state devices, semiconductor devices, organic semiconductor devices, etc., can solve the problems of easy breakage and poor bending resistance of the encapsulation part of flexible OLED devices, so as to ensure bending resistance. Folding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

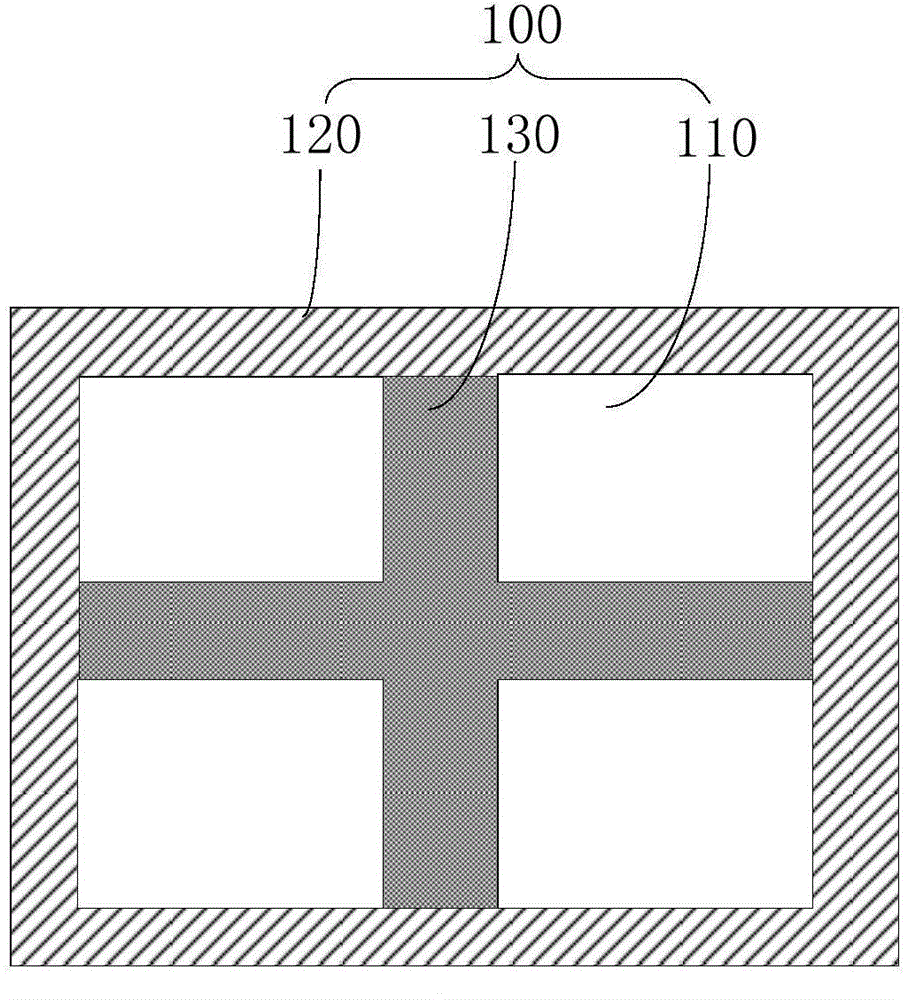

[0025] refer to figure 1 , a structural schematic diagram of the first embodiment of the mask plate of the present invention, the mask plate 100 includes a hollowed out area 110 and a non-hollowed out area 120 arranged around the hollowed out area 110; It is arranged in the hollowed out area 110 and connected to the non-hollowed out area 120 from the beginning to the end.

[0026] The hollow area 110 is a part removed by laser cutting, photolithography and etching to form a hollow shape. During coating, a large amount of coating material can pass through the hollow area 110 to form a thicker film layer.

[0027] The non-hollowed-out area 120 is the part that has not been processed. During coating, the coating material cannot pass through the non-hollowed-out area 120 and cannot form a film layer.

[0028] The semi-hollowed-out area 130 is a partially hollowed-out area and a partially non-hollowed-out area. During coating, a small amount of coating material can pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com