Production method for composite material elastomer navigation mark floating drum

A production method and composite material technology, applied in the field of navigation mark production, can solve the problems of low production efficiency, time-consuming, and the navigation mark buoy can not meet the technical progress of navigation mark, and achieve the effect of convenient and fast production, material quality, and good product integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

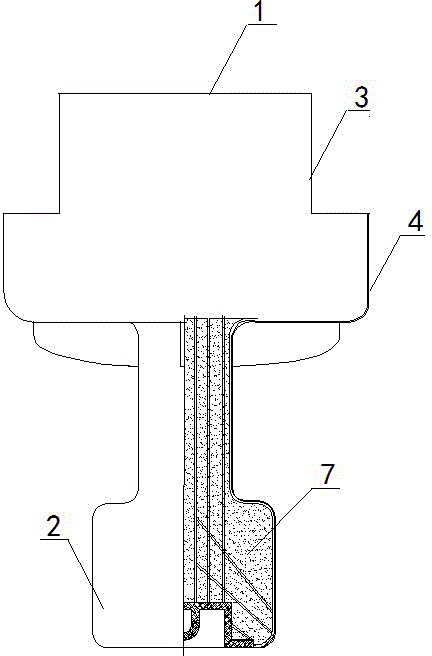

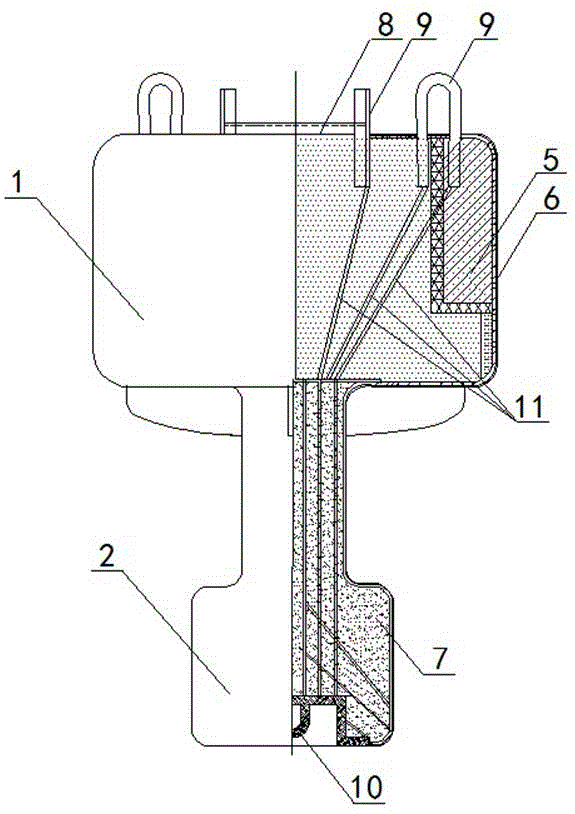

[0021] (1) First make the master model of floating drum, press figure 1 Shown shape makes the model of buoyant drum, and buoyant drum of the present invention is segmented cylinder shape, comprises drum body 1 and tailpipe 2, and drum body 1 is divided into the upper side 3 of the upper part of the drum, and the lower side 4 of the lower part of the drum body. Embodiment The diameter of the side 3 on the drum body is 1900 millimeters, the diameter of the lower side 4 of the drum body is 2400 millimeters, the height of the lower side 4 of the drum body is 970 millimeters, and the height of the side 3 on the drum body is 1460 millimeters. After the mold is made, press The conventional method for preparing FRP composite material is to prepare the main body of drum body 1 and tailpipe 2 with FRP composite material on the mold, so that the thickness of drum body 1 and tailpipe 2 reaches 8-12 mm; the preparation steps are:

[0022] Spray the gel coat on the surface of the product on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com