Tempered vacuum glass and production method thereof

A vacuum glass and glass technology, which is applied in the field of tempered vacuum glass and its production, can solve the problems of tempered glass strength decrease, glass annealing, residual stress decrease, etc., and achieve the effect of improving quality, not easy to fall off, and improving pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

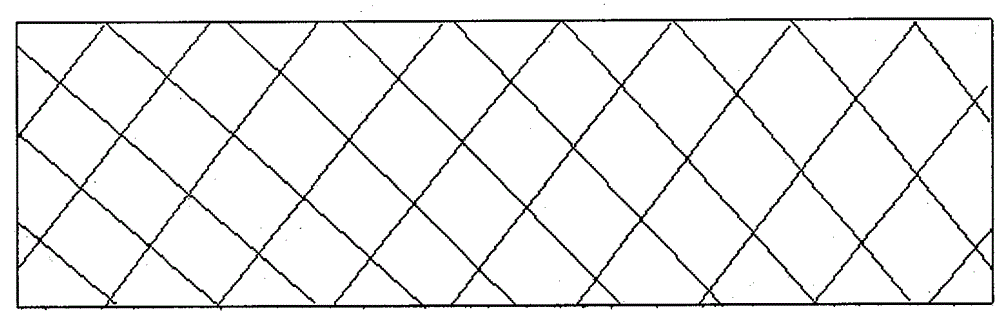

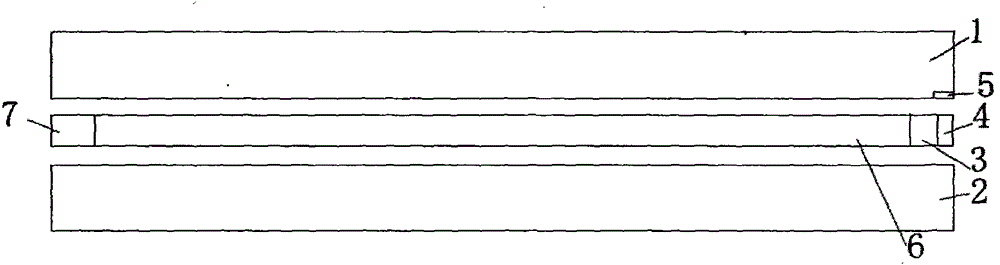

[0043] Such as figure 2 Shown, a kind of toughened vacuum glass, comprises upper glass 1, lower glass 2 and is arranged on the support 6 between the two, and support 6 is a mesh support (such as image 3 ), the size of the mesh support is smaller than the size of the upper and lower glass by 3cm, the upper and lower glass is sealed with PVB material 3 around, and an exhaust groove 5 is arranged on one side, so that the two pieces of glass are hollow to form a vacuum chamber, The outer side of the PVB material 3 is further sealed with tin 4, the width of the tin is preferably 0.3 cm, and the width of the PVB material is preferably 2 cm.

[0044] The production method of above-mentioned tempered vacuum glass is:

[0045] 1) According to the shape and size of the tempered vacuum glass to be produced, cut two pieces of glass of the required size, and perform edge grinding, chamfering, cleaning and drying;

[0046] 2) Place a mesh support between the upper and lower glass, and r...

Embodiment 2

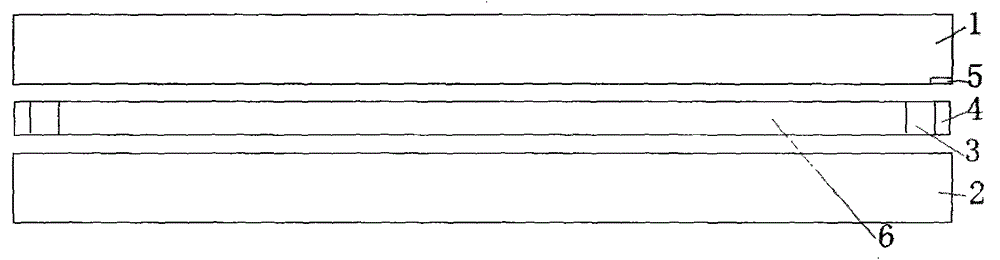

[0051] Such as figure 1 Shown, a kind of toughened vacuum glass, comprises upper and lower glass and is arranged between the mesh support (such as image 3 ), the size of the support is smaller than the size of the upper and lower glass 2.5cm, the upper and lower glass is sealed with PVB material around, and an exhaust groove 5 is arranged on one side, so that the two pieces of glass are hollow to form a vacuum chamber, and the PVB material 3 The outer side is further sealed with tin 4, the width of tin is 0.5cm, and the width of PVB material is 2cm.

[0052] The production method of above-mentioned tempered vacuum glass is:

[0053] 1) According to the shape and size of the tempered vacuum glass to be produced, cut two pieces of glass of the required size, and perform edge grinding, chamfering, cleaning and drying;

[0054] 2) Place a mesh support between the upper and lower glass, and reserve a space of 2.5cm around the glass;

[0055] 3) Coating PVB material on the four ...

Embodiment 3

[0059] A kind of tempered vacuum glass, including upper, middle and lower glass and the dot-shaped protruding substances arranged in arrays between two glasses (such as Figure 4 ), its overall size is smaller than the size of the upper and lower glass by 2cm, and one side corresponding to the upper, middle and lower glass is sealed with PVB material, and an exhaust groove is arranged on the side, the width of the PVB material is 2cm, and the other sides The frame is printed with low temperature solder.

[0060] The production method of above-mentioned tempered vacuum glass is:

[0061] 1) According to the shape and size of the tempered vacuum glass to be produced, cut two pieces of glass of the required size, and perform edge grinding, chamfering, cleaning and drying;

[0062] 2) Print dot-shaped protrusions arranged in an array in the middle of the upper, middle and lower glass, and reserve a space of 2 cm around the glass;

[0063] 3) Coat one side of the upper, middle an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com