A whole fraction crude benzene hydrogenation process

A technology of whole distillate and crude benzene, which is applied in the field of coal chemical industry, can solve the problems of easy coking and prolong the operation period, and achieve the effect of reducing pressure, expanding sources and accelerating catalyst coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

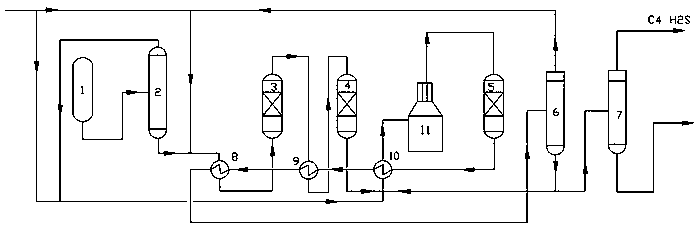

Method used

Image

Examples

Embodiment 1

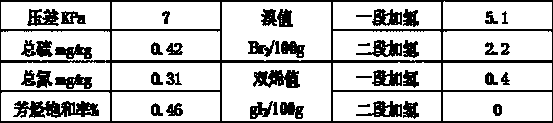

[0039] The raw material is coking crude benzene, and its components and mass fraction are as follows: total aromatics 93.4%, diene value 1.5gI 2 / 100g, bromine value 6.4gBr 2 / 100g, total sulfur 6546mg / kg, total nitrogen content 899mg / kg. The hydrogenation reaction conditions are as follows: one-stage hydrogenation reaction temperature is 70℃, pressure is 2.0MPa, and space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 400:1; the reaction temperature of the second stage hydrogenation is 210℃, the pressure is 4.0MPa, and the space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 600:1; the three-stage hydrogenation reaction temperature is 270℃, the pressure is 3.0MPa, and the space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 600:1, and there is no circulating material at the entrance of the three-stage reactor. After 90 days of continuous operation of the hydrogenation reaction, the results are shown in Table 2.

[0040] Table 2. Example 1...

Embodiment 2

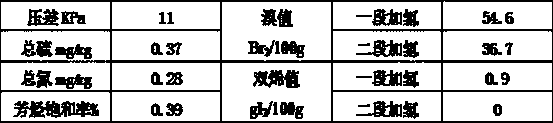

[0043] The raw material is crude benzene from coal-to-liquid, and its components and mass fraction are as follows: total aromatics 52.7%, diene value 9.8gI 2 / 100g, bromine value 68.3gBr 2 / 100g, total sulfur 3582mg / kg, total nitrogen content 940mg / kg. The hydrogenation reaction conditions are: one-stage hydrogenation reaction temperature is 150℃, pressure is 4.0MPa, and space velocity is 0.5h -1 , Hydrogen-to-oil volume ratio 800:1; second-stage hydrogenation reaction temperature is 190℃, pressure is 2.0MPa, space velocity is 2.0h -1 , Hydrogen-oil volume ratio 800:1; three-stage hydrogenation reaction temperature 310℃, pressure 2.0MPa, space velocity 0.5h -1 , The volume ratio of hydrogen to oil is 300:1, and the volume ratio of fresh feed to recycled feed in the three-stage reactor is 1:2. After 90 days of continuous operation of the hydrogenation reaction, the results are shown in Table 3.

[0044] Table 3. Hydrogenation results of Example 2

[0045]

Embodiment 3

[0047] The raw material is a 1:1 mixture of crude benzene from coking and crude benzene from coal to oil. The components and mass fractions are as follows: total aromatics 75.6%, diene value 6.1gI 2 / 100g, bromine value 36.8gBr 2 / 100g, total sulfur 4516mg / kg, total nitrogen content 873mg / kg. The hydrogenation reaction conditions are: one-stage hydrogenation reaction temperature is 110℃, pressure is 3.0MPa, and space velocity is 2.0h -1 , The volume ratio of hydrogen to oil is 600:1; the second-stage hydrogenation reaction temperature is 160℃, the pressure is 3.0MPa, and the space velocity is 0.5h -1 , The volume ratio of hydrogen to oil is 400:1; the three-stage hydrogenation reaction temperature is 350℃, the pressure is 4.0MPa, and the space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 450:1, and the volume ratio of fresh feed to recycled feed in the three-stage reactor is 1:1. After 90 days of continuous operation of the hydrogenation reaction, the results are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com