Fluidized bed hydrogenation system and hydrogenation method

A hydrogenation system and fluidized bed technology, applied in the field of hydrogenation, can solve the problems of low utilization rate of reactor effective space, inconvenient maintenance and repair, low utilization rate of catalyst, etc. The effect of long maintenance and operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

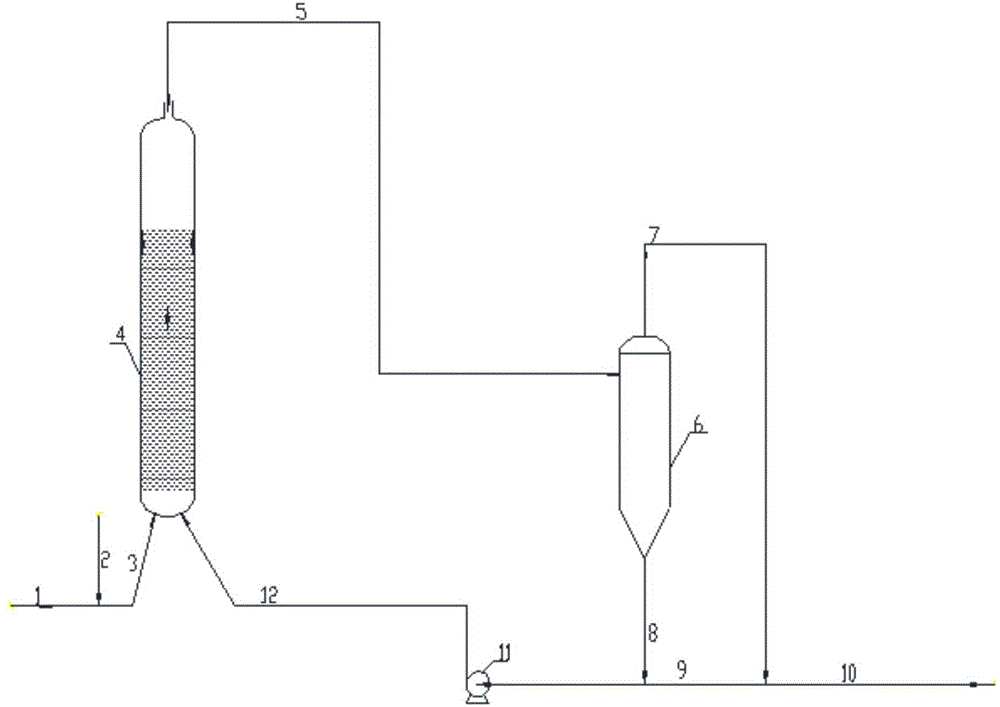

[0038] Such as figure 1 Shown, a fluidized bed hydrogenation system.

[0039] Including: a fluidized bed hydrogenation reactor 4 and an intermediate separation tank 6; the bottom of the fluidized bed hydrogenation reactor 4 is provided with a raw material inlet and a circulating oil inlet, and the top outlet of the fluidized bed hydrogenation reactor 4 is connected to the intermediate separation tank. The outlet pipeline at the bottom of the separation tank 6 is divided into two branches, one is connected to the bottom of the fluidized bed hydrogenation reactor 4, and the other branch is combined with the pipeline at the top of the intermediate separation tank 6 and sent out of the boundary.

[0040] in,

[0041] The fluidized bed hydrogenation reactor 4 is an upflow fluidized bed reactor.

[0042] The catalyst bed layer of the fluidized bed hydrogenation reactor 4 is an ebullated bed.

[0043] The bottom of the intermediate separation tank is conical with a taper of 30 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com