Modified kerosene composition

A technology of composition and kerosene, which is applied in the field of kerosene composition and fuel with improved antiknock performance, can solve the problems of no antiknock agent addition, etc., and achieve the elimination of fuel knock combustion, the improvement of limit knock power, and the induction period of spontaneous combustion prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

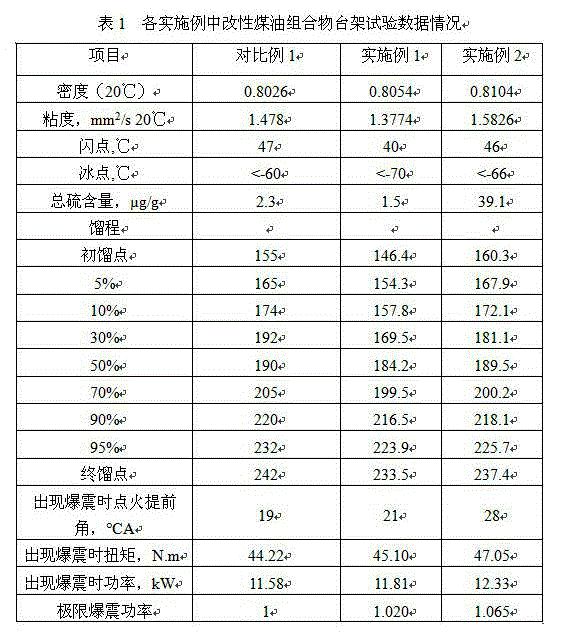

[0016] No. 3 jet fuel and xylene meeting GB6537-2006 are added into the container, wherein No. 3 jet fuel accounts for 87% of the total mass, and then mixed uniformly to form a modified kerosene composition. The flash point index of the modified kerosene composition is 40°C, the freezing point index is less than -70°C, used for bench test of ignition heavy oil piston engine. Compared with No. 3 aviation kerosene, the limit detonation power increased by 2.0%. The test results are shown in Table 1.

[0017] This test is a horizontally opposed four-cylinder water-cooled four-stroke aviation piston engine cylinder direct injection test prototype. In order to protect the safety of the engine, the experimental program selects the engine speed at 2500 rpm, the throttle opening at 36%, and the mixture gas concentration at 0.90 (power mixture concentration), and compares the maximum ignition advance angle height without knocking phenomenon when using different fuels. .

Embodiment 2

[0019] Add No. 3 jet fuel and isobutenylamide isoheptyl ester conforming to GB6537-2006 into the container, wherein No. 3 jet fuel accounts for 95% of the total mass, and then mix uniformly to form a modified kerosene composition. The modified kerosene composition The flash point index is 46°C, and the freezing point index is less than -66°C, which is used for bench test of ignition heavy oil piston engine. The test method is the same as in Example 1. Compared with No. 3 aviation kerosene, the limit detonation power has been improved by 6.5%. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com